Abstract

Due to the vibration (dynamic) effect on the path of the load from the rolling stock, reinforced concrete sleepers cannot withstand. Hidden and obvious defects appear in them, sometimes leading to their complete destruction. The article presents the results of a computational analysis of prestressed reinforced concrete sleepers performed using finite element mechanical and mathematical modeling in the ANSYS 2021 R2 program. Comparative strength static and dynamic calculations were performed for experimental sleeper samples of “version 1 concrete grade B40” (type Sh-1) and “version 2 concrete grade B50” (type SH-2). The results of laboratory and full-scale (operational) tests of prestressed reinforced concrete sleepers after their installation on experimental sections of the railway line are presented. The purpose of this study was to identify the main causes of cracking and failure of reinforced concrete sleepers, in order to produce improved samples of prestressed concrete sleepers. The economic development of the railways of the Republic of Kazakhstan, as well as the operational safety of passengers and cargo, directly depends on this.

1. Introduction

Railroad track is a complex system consisting of the base, subgrade, ballast, sleepers, fasteners and rails [1-3]. On the territory of Kazakhstan there are railroad tracks where there are problems with reinforced concrete sleepers at the national company JSC NC KTZh and private companies such as Integra Construction KZ LLP, Kazrailways LLP, Tengizchevroil LLP and others. Due to vibration (dynamic) impact on the track load from the rolling stock reinforced concrete sleepers do not withstand [4-6]. Hidden and obvious defects appear in them, sometimes leading to their complete destruction. The economy, development and operational safety of passengers and cargoes directly depend on this.

For example, according to the results of MDK measurements, 864 broken reinforced concrete sleepers were identified on the sections of the overhaul of the track Sary-Oba – Yerkenshilik in 2019, 889 broken sleepers were identified on the sections of 2020, and 571 broken sleepers were identified on the sections of 2021. In this regard, the national company JSC NC KTZh identified this problem and raised the issue of its solution. The program and methodology of testing of pre-stressed reinforced concrete sleepers for railway lines, track gauge 1520 mm, type SH version 2 (Concrete B40 and B50) was initiated. Firm BENT LLP, R.W.S. Concrete LLP, Magnetik LLP, KazSpal JSC, InnoTrack LLP and NORD Production Group LLP are domestic producers of prestressed reinforced concrete sleepers according to German technology Vollert of carousel type. These companies take an active part in the development and testing of new designs of reinforced concrete sleepers.

To predict the failure-free operation time of reinforced concrete sleepers on railroads, finite element models were calculated in the program ANSYS 2021 R2, which takes into account all possible defects in sleepers that appeared during the operation period [7], [8]. The obtained data are in full agreement with the data obtained during in-situ tests of prestressed reinforced concrete sleepers [9-11] with different fasteners [12-14]. In [15], [16], studies on a comparative review of American, European and Chinese standards for railway concrete sleepers and a review of agropotential wastes as constituents of railway sleepers are presented, confirming the adequacy of the results presented in this paper.

2. Modeling and analysis of dynamic characteristics

Finite element mechanical and mathematical modeling of prestressed reinforced concrete sleepers was carried out in the ANSYS 2021 R2 program. Comparative strength static and dynamic calculations of sleepers for concrete grades B40 and B50 were performed, the initial data were rearranged in Table 1.

Table 1Initial data for performing strength calculations of sleepers for concrete grades B40 and B50

Structure | Nominal size of under-rail platform | Min/max size | Maximum deviation | Concrete grade |

Firm BENT LLP | 193 | 193 | +8; –3 | B40 |

NORD Production Group LLP | 193 | 193 | +8 | B50 |

LLP Magnetik | 203 | 203 | +8; –3 | B40 |

JSC KazShpal | 193 | 193 | +8; –3 | B40 |

InnoTrack LLP | 210 | 210 | 0 | B50 |

R.W.S. Concrete LLP | 193 | 193 | +8; –3 | B50 |

Comparative calculations of the load-bearing capacity of sleepers. Vertical load 145 kN; The under-sleeping area is fixed as absolutely flat.

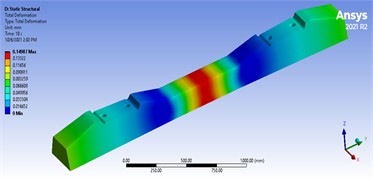

As a result of the calculation, it was found that the stress-strain state of the sleepers does not exceed the maximum permissible value when the base of the sleeper zone is absolutely flat. All sleepers can withstand a maximum vertical load of 27 tons. However, it can be observed that a standard sleeper with concrete grade B40 deforms more than a B50 sleeper with a thickened sub-rail.

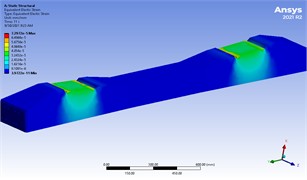

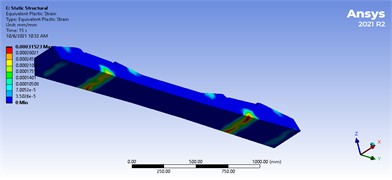

Fig. 1Calculation of the bearing capacity of sleepers (Elastic deformation)

a) Sleeper with concrete grade B50, thickness 210 mm. Elastic deformation was 0.04 mm

b) Sleeper with concrete grade B40, thickness 193 mm. Elastic deformation was 0.067 mm

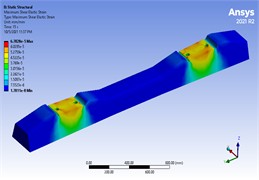

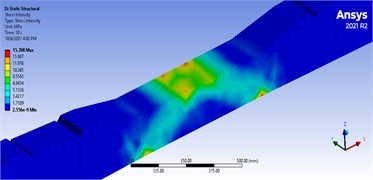

Calculation of the bearing capacity of sleepers in the presence of subsidence in the sleeper zone. The calculation results showed that in case of subsidence in the under-track zone, sleepers of B40 grade with a thickness of 193 mm cannot withstand the applied maximum load. A crack is formed under the sleeper in the area under the rails. B50 sleepers with thickness of 210 mm can withstand vertical load of 145kN.

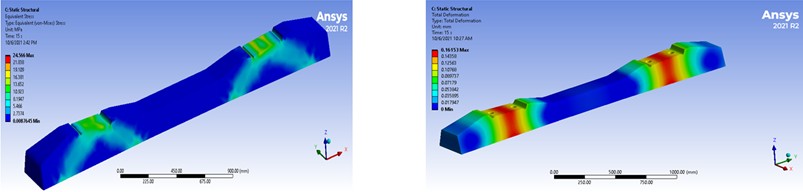

Stress-strain state of the central zone of sleepers. Stress intensity for sleepers B50 150 mm was 15 MPa, and for sleepers B40 with a center zone thickness of 145 mm 18.5 MPa. If the dynamic component from vibration is taken into account, the fracture occurs on B40 sleepers.

Fig. 2Calculation of the bearing capacity of sleepers (subsidence in the sleeper zone)

a) Compressive strength exceeded Fracture strength

b) Sleeper with concrete grade B50, thickness 210 mm Equivalent stresses amounted to 22 MPa at compressive strength 29 MPa

c) Sleeper with concrete grade B40 thickness 193 mm Equivalent stresses were 34 MPa at compressive strength of 36 MPa

Fig. 3Stress-strain state of sleepers (central zone)

a) Sleeper with concrete grade B50, thickness 150 mm stress 15 MPa

b) Sleeper with concrete grade B40, thickness 145 mm stress 18.5 MPa

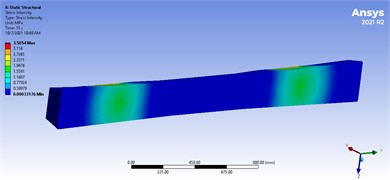

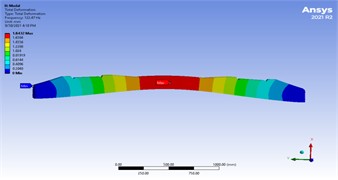

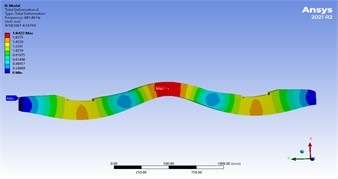

Results of dynamic calculations. Dynamic calculations show that the unevenness of the sleeper zone leads to the appearance of forced vibrations under the influence of train load. Coincidence of forced vibrations with natural frequencies of sleepers leads to resonance phenomena causing sleeper failure (cracks in the central and closer to the under-rail part. Red zones). The maximum amplitude of vibrations amounted to 1.8 mm.

Fig. 4Deformable finite element model of sleepers (dynamics)

a) Sleeper with concrete grade B50

b) Sleeper with concrete grade B40

3. Test methodology

Program and methodology of tests of prestressed reinforced concrete sleepers for elastic rail coupling with threaded rail attachment to the sleeper. At the first stage prototypes of “execution 1” (type Sh-1) and “execution 2” (type Sh-2) were manufactured. LLP “R.W.S Concrete” (R.W.S. Concrete) provided pre-stressed reinforced concrete sleepers for railroads of 1520 mm gauge with/without rail fastening (drawing RWS 2020 Sh-02 (type Sh-1) according to GOST 33477-2015 in the amount of 100 pcs. Firm “BENT” LLP provided a batch of sleepers of Sh-2 type (GOST 33320-2015) in the amount of 100 pcs for full-scale operational tests in the laboratory of “InnoTrack” LLP. Together with the Research Center of “KazTsZhT” LLP, preliminary (factory) tests (Figs. 5 and 6) and their subsequent laying on the railroad were carried out.

Fig. 5Testing of concrete specimens

a) Bending tests

b) Determination of cubic strength of concrete

c) Outrigger Sdue S3

d) Outrigger Sdu 9

Fig. 6Testing of reinforced concrete sleeper

4. Test results

The test results of concrete specimens (cubes and prisms) concrete class B50 are summarized in Table 2.

Table 2Design stresses of 16.5 m and 23.6 m spans

Name of indicators | Designation ND designation for test methods | ND requirements | Actual results |

Concrete strength, MPa, not less | GOST 10108-2012 | 65,5 | 66.2 |

Frost resistance F1 300: | GOST 10060-2012 | 8 cycles | 8 cycles |

– weight loss, % not more | 2 | 1 | |

– strength, MPa, not less | 58,9 | 63.9 | |

Concrete water permeability, not less | GOST 12730.5-84 | W8 | W14 |

Resistance of concrete to air penetration, s/cm3 | 9,5-13,7 | 32,7 |

The results of preliminary (factory) tests of reinforced concrete sleepers of concrete class B40 and B50 of InnoTrack LLP and Firma BENT LLP are presented in Table 3.

Table 3Technical indicators of preliminary (factory) tests of reinforced concrete sleepers of concrete class B40 and B50

No | Name of indicators | Technical indicators of sleeper samples | |||||

В40 | В50 | ||||||

1 | Crack resistance of sleepers | Sample 1 | Sample 2 | Sample 3 | Sample 1 | Sample 2 | Sample 3 |

7 days after demolding | 7 days after demolding | ||||||

Under-rail cross-section (height) | 10.6 MPa (269 kN) (210 mm) | 10.2 MPa (258.9 kN) (210 mm) | 10.4 MPa (264 kN) (210 mm) | 12.5 MPa (317 kN) (210 mm) | 11.4 MPa (289 kN) (210 mm) | 11.9 MPa (302 kN) (210 mm) | |

Middle section (height) | 5.3 MPa (134 kN) (150 mm) | 5.1 MPa (129 kN) (150 mm) | 5.2 MPa (132 kN) (150 mm) | 5.5 MPa (139 kN) (150 mm) | 6.2 MPa (157 kN) (150 mm) | 7.0 MPa (177 kN) (150 mm) | |

2 | Weight of sleeper | 274 | 274 | ||||

3 | Dowel bursting | Sdu 25 – 100 kN | Sdu 25 – 93 kN | ||||

4 | Compressive strength of concrete cube specimens | 43,9 MPa | 40,65 MPa | 41,56 MPa | 55,7 MPa | 58,1 MPa | 53,04 MPa |

5 | Flexural strength of concrete prism specimens | 2000 kgf = 5,4 MPa 1600 kgf = 4,33 MPa 1800 kgf = 4,9 MPa | |||||

6 | Protective layer thickness: | ||||||

From top | Less -25 mm | Less -25 mm | |||||

Bottom | At least 30 mm | At least 30 mm | |||||

Table 4Technical parameters of preliminary (factory) tests of reinforced concrete sleepers of concrete class B40 and B50

No | Name of indicators | Technical indicators of sleeper samples | |||||||

В40 | В50 (Hр-193 mm)1 | В50 (Нр-210 mm)2 | |||||||

1 | Crack resistance of sleepers | Sample 1 (1 day) | Sample 2 (9 day) | Sample 1 | Sample 2 | Sample 3 | Sample 1 | Sample 2 | Sample 3 |

Under-rail section (height) | 147 kN (196 mm) | 190 kN (195 mm) | 216 kN (194 mm) | 166 kN (190 mm) | 173 kN (191 mm) | 162 kN (207 mm) | 175 kN (209 mm) | 176 kN (218 mm) | |

Middle section (height) | 106 kN (142 mm) | 120 kN (146 mm) | 178 kN (147 mm) | 161 kN (145 mm) | 160 kN (148 mm) | 197 kN (161 mm) | 166 kN (154 mm) | 168 kN (157 mm) | |

2 | Sleeper weight | 260 кг | 290 кг | ||||||

3 | Dowel breakout | Dowel SDUe S3 - 100 kN | Dowel SDU 9 - 60 kN | Dowel SDUe S3 - 95 kN | |||||

4 | Compressive strength of concrete cube specimens3 | 36,28 MPa | 53,44 MPa | ||||||

5 | Flexural strength of concrete specimen-prisms4 | 21,9 kgf = 2,14 MPa 19,1 kgf = 1,87 MPa | |||||||

6 | Protective layer thickness: | ||||||||

-from top | 26 mm | 28 mm | 29 mm | 26 mm | 27 mm | 28 mm | 39 mm | 37 mm | |

-bottom | 32 mm | 34 mm | 36 mm | 33 mm | 36 mm | 58 mm | 49 mm | 48 mm | |

**These sleepers were demolished on 04.11.2020, i.e. 11 months passed from the moment of demolition to the moment of testing **These sleepers were demolded on 20.10.2021 at 05:00, i.e. 6 hours passed from the moment of demolding to the moment of testing ***These concrete cube specimens were demolded on 13.10.2021, i.e. 7 days have passed from the moment of demolding to the moment of testing ****These concrete specimen-prisms were demolded on 21.10.2021 at 08:00, i.e. 3 hours elapsed from the moment of demolding to the moment of testing. | |||||||||

The results of preliminary (factory) tests of reinforced concrete sleepers of concrete class B40 and B50 of NORD Production Group LLP, Magnetic LLP and R.W.S. Concrete LLP are presented in Table 4.

5. Discussion of the results

After a short period of operation of sleepers of type Sh-1 and type Sh-2 laid on the main tracks, defects of sleepers were made at the following experimental sites.

1st section - Shiderty station 14.12.2021 - inspection of prestressed reinforced concrete sleepers type SH-2 with concrete grade B50 introduced in operational (full-scale) tests 12.11.2021 on the section Ereimentau-Ekibastuz, Bozshakol-Shiderty odd track 258 km pk 4-5. Number of laid sleepers: 100 sleepers produced by InnoTrack LLP and 95 sleepers produced by Firma BENT LLP. Established speed of trains movement: 110-80 km/hour, freight intensity of the section: 61.8 mln tn km br/km.

During the inspection it was found out that no defects were found on sleepers produced by Firma BENT LLP during the operational tests. On one sleeper produced by InnoTrack LLP in the joint of the equalizing span after laying there was a defect in the form of a crack from the outer recess of the under-rail platform to the bottom of the sleeper. There are no rails hijacking, sleeper’s displacement according to the diagram. Rail gauge 1520-1524 mm.

2nd section - Shymkent station 29.03.2022g - inspection of pre-stressed reinforced concrete sleepers type SH-1 with concrete grade B40, and type SH-2 with concrete grade B50, produced by R.W.S Concrete LLP put into operational testing 08.12.2021. on the section Shymkent-Arys 2, Igilik-Badam odd track 3262km pc, 3261km pc. Number of laid sleepers: 200 pcs. Established speed of trains: 120-80 km/hour, freight intensity of the section: 36.6 mln km br/km, missed tonnage: 634+490.6 mln km br/km.

During the inspection it was found that no defects of sleepers were detected during the operational tests. There are no rail hijackings, sleepers mixing on the epurea. Rail gauge is 1519-1520 mm. At repeated screwing of screws of Sh-1 type with concrete grade B40 one screw was broken. According to the readings of the track measuring car for 21.03.2022g. 3261 km-3262 km by 150 points (satisfactory, number of 2 degree - 72 pieces). During re-inspection of the 1st section - station. Shiderty 09.09.2022 Yereymentau-Ekibastuz section, Bozshakol-Shiderty odd track 258 km PK 4-5. Date of laying sleepers: 9-12.11.2021 y, freight intensity of the section for 2021: 56.07 million tons km br. / km, set train speed: 110-80 km/hour, rail gauge 1520-1524 mm, it was revealed that the sleepers of InnoTrack LLP laid in the railroad track at the section 258 km pk4 have the following defects: sleepers with a transverse crack in the middle - 8 pcs; chipped sleepers on the right side from the end - 2 pcs; under-rail crack on the left - 16 pcs; sleepers with a transverse crack on both sides - 7 pcs; sleepers with a transverse crack on the internal chipping with an opening of 5 mm - 1 pc.

During the inspection of the sleepers laid in the railroad track of «Firm BENT» LLP on the section 258 km pk4 it was found that: no bonding on the left - 3 pcs; under-rail crack on the right - 2 pcs; under-rail crack on the left - 5 pcs; under-rail spalling of concrete - 4 pcs; transverse crack - 2 pcs; longitudinal crack on the left - 5 pcs; sleepers with under-rail crack on the right with 10 mm opening, broken terminal - 1 pc; destruction of sleeper on the left, rubbing on the right - 2 pcs; longitudinal crack on the left up to the middle of the sleeper - 2 pcs.

6. Conclusions

For the period from 12.11.2021 to 09.09.2022 on the section Ereimentau-Ekibastuz, Bozshakol-Shiderty odd track 258 km pk 4-5 laid experimental prestressed reinforced concrete sleepers type SH-1 and type SH-2, on which passed 56.07 million tons of br/km with the established speed of trains 110-80 km/hour. Sleepers received the following defects: transverse cracks - in the middle and on both sides, on the inner spall with an opening of 5 mm; under-rail crack - on the left and right, with an opening of 10 mm, broken terminal, lack of bonding, spalls on the right side of the sleeper from the end, destruction of the sleeper, longitudinal crack on the left to the middle of the sleeper.

In the program ANSYS 2021 R2 it is realistic to monitor the stress-strain state of reinforced concrete sleepers, to perform calculations of bearing capacity in the presence of subsidence in the under-tie zone, the central zone of sleepers, as well as to simulate the dynamic operation of sleepers, taking into account all the identified defects during the period of operation.

The obtained results will help manufacturers of reinforced concrete sleepers to produce sleepers able to withstand vibrations and increased dynamic loads from rolling stock.

References

-

M. H. Murray and J. Bian, “Ultimate limit states design of concrete railway sleepers,” Proceedings of the Institution of Civil Engineers – Transport, Vol. 165, No. 3, pp. 215–223, Aug. 2012, https://doi.org/10.1680/tran.10.00048

-

F. Çeçen, B. Aktaş, H. Öztürk, I. Öztürk, and M. B. Navdar, “Improving LUR testing accuracy and practicability for prestressed concrete sleepers through bending stiffness and visco-plastic deflection-based analysis techniques,” Case Studies in Construction Materials, Vol. 22, p. e04545, Jul. 2025, https://doi.org/10.1016/j.cscm.2025.e04545

-

M. Siahkouhi, X. Li, V. Markine, and G. Jing, “Experimental and numerical study on the mechanical behavior of Kunststof Lankhorst Product (KLP) sleepers,” Scientia Iranica, Vol. 28, No. 5, pp. 2568–2581, Mar. 2021, https://doi.org/10.24200/sci.2021.57165.5096

-

S. A. Kosenko, I. S. Bondar, M. Y. Kvashnin, and G. I. Chekmareva, “Ensuring the passage of freight trains with increased axle loads on railway bridges,” Transportation Research Procedia, Vol. 61, pp. 627–635, Jan. 2022, https://doi.org/10.1016/j.trpro.2022.01.101

-

I. S. Bondar, G. B. Karibaeva, and A. K. Kurbenova, “Vibration diagnostics of transportation structures on railroads,” Vibroengineering Procedia, Vol. 54, pp. 109–115, Apr. 2024, https://doi.org/10.21595/vp.2024.24093

-

L. Raif, B. Puda, J. Havlík, and M. Smolka, “Design of high-speed turnouts and crossings,” in IOP Conference Series: Materials Science and Engineering, Vol. 236, p. 012044, Sep. 2017, https://doi.org/10.1088/1757-899x/236/1/012044

-

K. Aniołek and J. Herian, “Numerical modeling of load and stress on the contact surface of a turnout and a railway vehicle,” Journal of Transportation Engineering, Vol. 139, No. 5, pp. 533–539, May 2013, https://doi.org/10.1061/(asce)te.1943-5436.0000510

-

I. S. Bondar, D. T. Aldekeyeva, and Z. K. Ospanova, “Stress-strain states of reinforced concrete spans of a railroad overpass using a spatial finite element model,” Vibroengineering Procedia, Vol. 54, pp. 320–326, Apr. 2024, https://doi.org/10.21595/vp.2024.24086

-

A. Németh et al., “Laboratory and numerical investigation of pre-tensioned reinforced concrete railway sleepers combined with plastic fiber reinforcement,” Polymers, Vol. 16, No. 11, p. 1498, May 2024, https://doi.org/10.3390/polym16111498

-

N. I. Begmatov and N. R. Muhammadiyev, “Experimental determination of the rigidity of a rail thread,” Railway Transport: Current Challenges and Innovations, Vol. 3, No. 1, pp. 5–11, Jan. 2021, https://doi.org/10.24412/2181-953x-2021-1-5-11

-

R. P. Randi, L. M. Trautwein, and A. C. Dos Santos, “Aspects of modeling prestressed concrete sleepers subjected to positive moment test at midspan,” Buildings, Vol. 14, No. 8, p. 2387, Aug. 2024, https://doi.org/10.3390/buildings14082387

-

A. M. Zhangabylova, I. S. S. Bondar, M. Y. Kvashnin, A. M. Ablyazova, and A. D. Konyasbai, “Analysis intermedii clausorum ferriviariorum operationis sub onere operationali,” Bulletin of KazATK, Vol. 133, No. 4, pp. 55–65, Apr. 2024, https://doi.org/10.52167/1609-1817-2024-133-4-55-65

-

G.-A. Khalfin and K. Umarov, “The work of intermediate rail fasteners on mountain sections of railways,” in 3rd International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2021 AS), Vol. 2612, p. 040023, Jan. 2023, https://doi.org/10.1063/5.0126396

-

V. Hovorukha, “Studying and improving intermediate rail fastening of rail transport,” in E3S Web of Conferences, Vol. 109, p. 00028, Jul. 2019, https://doi.org/10.1051/e3sconf/201910900028

-

X. Li, S. I. Doh, G. Jing, B. W. Chong, A. L. Suil, and S. C. Chin, “A comparative review on American, European and Chinese standard for railway concrete sleeper,” Physics and Chemistry of the Earth, Parts A/B/C, Vol. 124, p. 103073, Dec. 2021, https://doi.org/10.1016/j.pce.2021.103073

-

S. C. Khong, J. J. Yee, S. I. Doh, and S. C. Chin, “A review of agro-potential waste as a constituent in railway sleepers,” Physics and Chemistry of the Earth, Parts A/B/C, Vol. 128, p. 103238, Dec. 2022, https://doi.org/10.1016/j.pce.2022.103238

About this article

The authors have not disclosed any funding.

The authors would like to thank JSC NC KTZh, Firma BENT LLP, R.W.S. Concrete LLP, Magnetik LLP, KazSpal JSC, InnoTrack LLP and NORD Production Group LLP for the information provided.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.