Abstract

Original calculation schemes of the motor-axle bearing and the distribution of heat flows in the process of heat removal from the surface layer of lubricant to the axle journal of the wheel pair and to the motor-axle bearing liner are proposed, taking into account its middle layer. In order to substantiate the maximum amount of heat released in the motor-axle bearings of a freight diesel locomotive of the 2TE10 series and caused by the action of friction forces in the zone of contact their with the journals of the axles of the wheel pairs, taking into account the theoretical foundations of heat transfer and the accepted assumptions in the specified calculation schemes, analytical dependencies were obtained to determine the quantities characterizing heat removal from the mentioned motor-axial bearings using three flows. As a result of implementing the proposed analytical dependencies and performing numerical calculations, it was proved that the operation of the studied motor-axial bearings is carried out in the semi-fluid friction mode and at negative temperatures of the external (atmospheric) air, their normal operation is not ensured due to the low proportion of heat removal by the lubricant, which does not exceed 1.5 percent, and therefore, this leads motor-axial bearings to premature wear and failure, and thereby reduces the operational reliability of the wheel-motor unit of diesel locomotives.

Highlights

- An analysis of the improvement of heat transfer processes in motor-axial bearings has been performed.

- A design scheme of a motor-axial bearing and heat removal from the surface layer of lubricant to the neck of the axle of the wheelset has been developed.

- The calculation of temperature fields at various loads and rotational speeds is performed.

- Optimal bearing designs and materials for improving heat transfer are proposed.

1. Introduction

Motor-axle sliding bearings are an antifriction liner in the form of a Babbitt layer coating and the surface of the wheel pair axle journal, separated by an oil film of axial oil, which are the responsible and connecting link of the wheel-motor unit of the locomotive.

Therefore, in order to ensure high operational reliability of the wheel-motor unit, the corresponding technical condition of the motor-axle bearings requires diagnostics of failures in order to eliminate them in advance and promptly.

Reliable and timely determination of the technical condition of motor-axial bearings is an urgent task for enterprises of the locomotive complex involved in the operation and repair of this unit.

The physical processes occurring in sliding bearings are complex and depend on many external and internal factors. In general, all problems arising during operation related to the technical condition of sliding bearings can be divided into three groups [1, 2]: problems with the condition of the working surfaces of the bearing; problems with the size of the gap between the journal of the wheelset axle and the antifriction liner; problems with the bearing capacity of the oil film.

In addition, the main and basic disadvantages of a typical motor-axial bearing are [3, 4]:

– Low load-bearing capacity of the oil wedge of the liner (increased wear and scuffing of the babbitt, heating).

– Lubricant entering through the gap of the motor-axle bearing along the axis of the wheelset into the gear housing (mixing lubricant compositions).

– Intensive consumption of lubricant compositions.

– Moisture entering the motor-axial bearing (stimulating the corrosive aggressiveness of petroleum acids, which have a destructive effect on non-ferrous metals).

– Dust entering the motor-axial bearing (decreased lubrication quality, increased likelihood of heating).

– Negative impact on the environment.

In addition, studies [5-7] by employees of the Department of Locomotives and Locomotive Economy of the Tashkent State Transport University noted a violation of the temperature regime of traction electric motors during the movement of rolling stock in real operating conditions of mainline diesel locomotives.

Recommendations and proposals of scientists [8-13] to improve the operational reliability of various types of bearings, including axle bearings of high-speed trains, obtained as a result of justification of vibration parameters and thermal characteristics for real operating conditions, undoubtedly have great scientific interest and of enormous practical significance, however, they did not study at all the issues related to the motor-axial bearings of traction electric motors of diesel locomotives.

The scientific novelty of this study is in the analysis of heat transfer processes in the motor-axial bearings of traction electric motors of diesel locomotives, taking into account the operating conditions [6-8]. The study of thermal fields under long-term operation conditions makes it possible to identify critical overheating zones. The results of the study can be used in the modernization of elements of the cooling system of locomotive traction electric motors in order to improve their operational reliability and efficiency in route of rolling stock.

This article is devoted to the theoretical analysis and assessment of the influence of temperature and lubrication conditions in the friction zone of motor-axle bearings with the axle journal of a wheelset on heat generation and heat dissipation, taking into account the ambient temperature (outside air).

2. Objects and methods of research

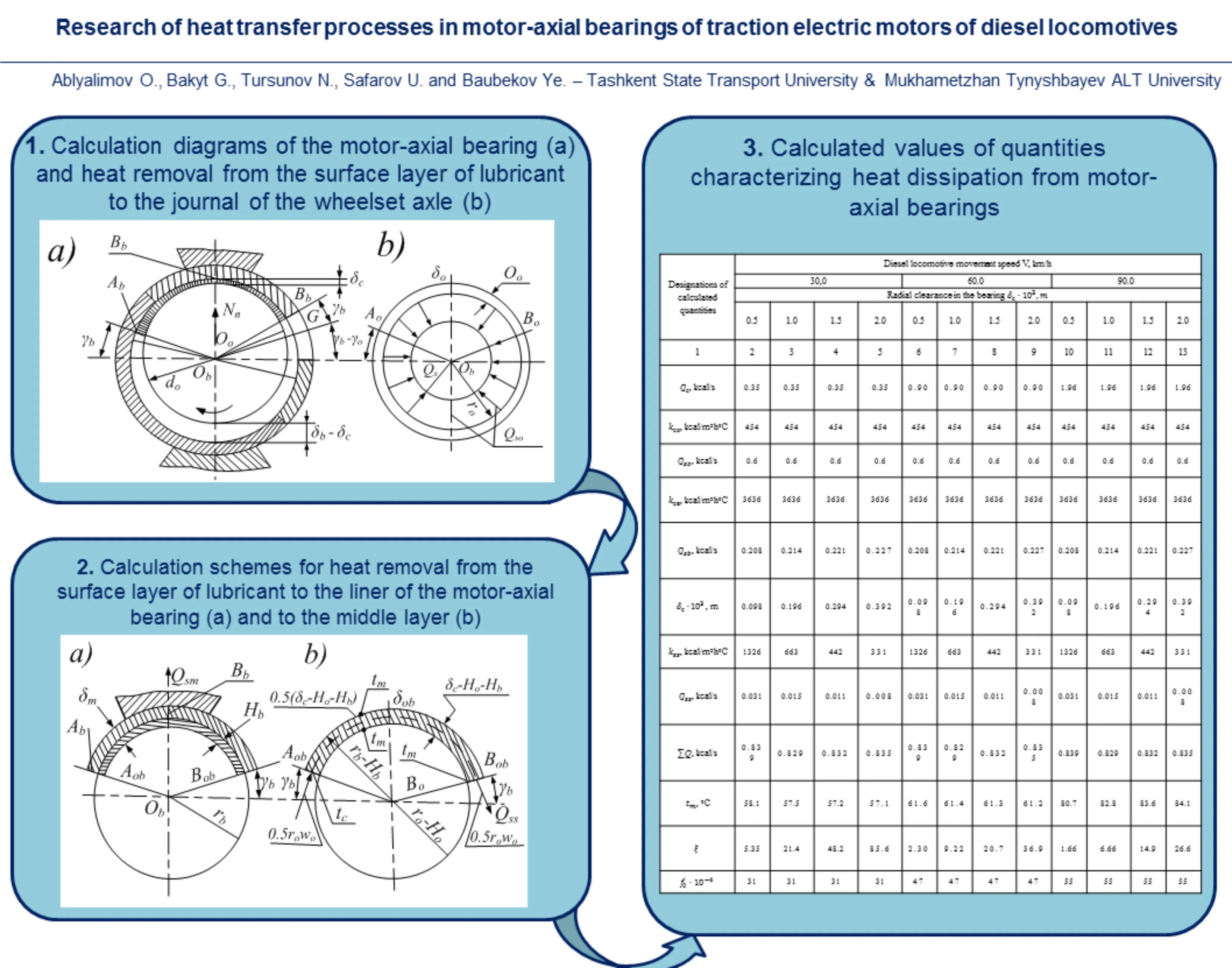

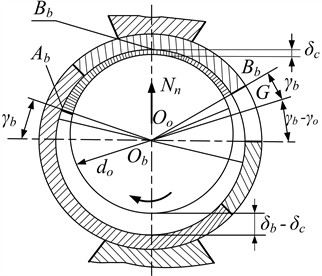

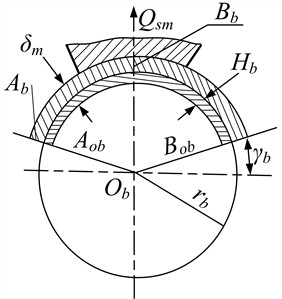

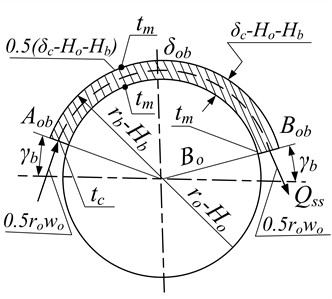

To study the influence of the temperature regime in the friction zone of the motor-axle bearing (MAB) with the wheel pair axle journal, calculation diagrams were drawn up (Fig. 1 and Fig. 2), taking into account the distribution of heat flows perceived by the wheel pair axle journal, the MAB liner and lubricant (grease).

Fig. 1Calculation diagrams of a) the motor-axial bearing and b) heat removal from the surface layer of lubricant to the journal of the wheelset axle

a)

b)

The following designations are introduced on the design diagrams: – heat released during MAB operation; – reduced radial load on the MAB liner; , , – length, radius and rotational speed of the bearing surface of the wheel pair axle journal; – thickness of the surface layer of lubricant, equal in magnitude to the height of micro-irregularities on the surface of the axle journal; – angle within which the loading zone is located; – thickness of the surface layer of lubricant, equal in magnitude to the height of micro-irregularities on the surface of the liner; – heat removed by the axle neck; , – radius and thickness of the insert MAB; – heat removed through the insert MAB; – average thickness of the lubricant layer in the loading zone; – radial clearance in the MAB; , – centers of rotation of the MFB liner and the axis of the wheelset; – heat removed by the lubricant; – average heating temperature of the surface layers of the lubricant in the loading zone; – average temperature of the middle layer of lubricant in the loading zone.

Fig. 2Calculation schemes for heat removal a) from the surface layer of lubricant to the liner of the motor-axial bearing and b) to the middle layer

a)

b)

Using the accepted notations, we will analyze the heat transfer in the motor-axial bearings of diesel locomotives of type 2TE10 (Fig. 1(a)).

It is known that during the operation of a motor-axial bearing, the heat generated due to the action of friction forces can be determined by the dependence [14, 15], namely:

where – mechanical equivalent of heat, ; – average friction coefficient depending on the lubrication mode.

The heat generated in the motor-axial bearing is removed by three main flows.

In the first flow, heat is transferred to the neck of the wheelset axle, then to the wheel center with a bandage, effectively cooled by atmospheric air when the diesel locomotive moves (see Fig. 1(b)), that is:

where – first flow heat transfer coefficient; – atmospheric air (environment) capacity.

In the second flow, heat is transferred to the section of the liners (see Fig. 2(a)) of the motor-axial bearing, located within the loading zone (corner ), that is:

where – heat transfer coefficient of the second stream; – heating temperature of the outer surface of the liners in the loading zone.

In the third flow, heat is removed from the surface layers , , (Fig. 2(b)) and , , to the middle layer, moving relative to the latter with an average linear speed of 0.5, that is:

where – third flow heat transfer coefficient.

Under normal operating conditions of motor-axial bearings, the maximum amount of heat removed by all three flows must exceed the amount of heat released from the action of friction forces, namely:

or taking into account Eqs. (1-4) we have the following:

from where, after transformations, it is possible to determine the average heating temperature of the lubricant in the surface layers in contact with the axle journal and liners of motor-axial bearings.

To determine the friction coefficient , we first use the well-known dependence [16] to determine the coefficient [16-18], which characterizes the type of rubbing bodies, their material and geometric dimensions, as well as the time and modes of heat release, taking into account the calculation schemes (Fig. 1 and Fig. 2), that is:

where 𝜂 – dynamic viscosity of the lubricant.

Preliminary analysis and calculations carried out using Eq. (7) showed that motor-axial bearings operate in the semi-fluid friction mode, therefore the friction coefficient will be determined by the formula [16]:

3. Results and their discussion

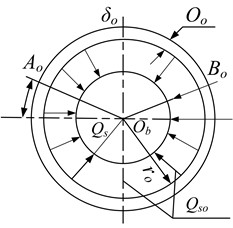

Using Eqs. (1-8), calculations were made for 12 modes (3 options for changing the speed movement of the diesel locomotive and 4 options for changing the radial clearance in the motor-axial bearings) at an ambient temperature +20 °C, the results of which are summarized in Table 1.

From the analysis of data in table. 1 shows that with an increase in the speed of the diesel locomotive, the heating temperature of the axial winter oil in the friction zone increases from 57.1 °C to 84.1 °C, and the share of heat removed by the lubricant is only 1-2 percent. In addition, we can also conclude that the lubrication of motor-axial bearings is carried out in the semi-fluid friction mode, since the mentioned coefficient and the friction coefficient lie in the range of 0.0031-0.0055 units, which are rises with increasing speed movement of the diesel locomotive.

Table 1Calculated values of quantities characterizing heat dissipation from motor-axial bearings

Designations of calculated quantities | Diesel locomotive movement speed V, km/h | |||||||||||

30,0 | 60.0 | 90.0 | ||||||||||

Radial clearance in the bearing ·103, m | ||||||||||||

0.5 | 1.0 | 1.5 | 2.0 | 0.5 | 1.0 | 1.5 | 2.0 | 0.5 | 1.0 | 1.5 | 2.0 | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

, kcal/s | 0.35 | 0.35 | 0.35 | 0.35 | 0.90 | 0.90 | 0.90 | 0.90 | 1.96 | 1.96 | 1.96 | 1.96 |

, kcal/m2h0C | 454 | 454 | 454 | 454 | 454 | 454 | 454 | 454 | 454 | 454 | 454 | 454 |

, kcal/s | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

, kcal/m2h0C | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 | 3636 |

, kcal/s | 0.208 | 0.214 | 0.221 | 0.227 | 0.208 | 0.214 | 0.221 | 0.227 | 0.208 | 0.214 | 0.221 | 0.227 |

∙103, m | 0.098 | 0.196 | 0.294 | 0.392 | 0.098 | 0.196 | 0.294 | 0.392 | 0.098 | 0.196 | 0.294 | 0.392 |

, kcal/m2h0C | 1326 | 663 | 442 | 331 | 1326 | 663 | 442 | 331 | 1326 | 663 | 442 | 331 |

, kcal/s | 0.031 | 0.015 | 0.011 | 0.008 | 0.031 | 0.015 | 0.011 | 0.008 | 0.031 | 0.015 | 0.011 | 0.008 |

∑, kcal/s | 0.839 | 0.829 | 0.832 | 0.835 | 0.839 | 0.829 | 0.832 | 0.835 | 0.839 | 0.829 | 0.832 | 0.835 |

, °C | 58.1 | 57.5 | 57.2 | 57.1 | 61.6 | 61.4 | 61.3 | 61.2 | 80.7 | 82.8 | 83.6 | 84.1 |

5.35 | 21.4 | 48.2 | 85.6 | 2.30 | 9.22 | 20.7 | 36.9 | 1.66 | 6.66 | 14.9 | 26.6 | |

∙10-4 | 31 | 31 | 31 | 31 | 47 | 47 | 47 | 47 | 55 | 55 | 55 | 55 |

To study the influence of ambient air temperature on heat generation and heat removal in motor-axial bearings, calculations were also made of the values characterizing the indicated heat generation and heat removal in motor-axial bearings for the most unfavorable variant (case) - of movement speed ( 90 km/h) of a diesel locomotive and the maximum radial clearance 2∙10-3 m in motor-axial bearings at 5 combinations of ambient air temperatures (+40, +20, 0, –20, –35) °C.

Calculations have shown that with a decrease in ambient air temperature , increases the viscosity of the axial winter lubricant from 0.018 to 15.0 N s/cm2, the friction coefficient from 0.002 to 0.058 units, but heat generation from 0.39 to 14.37 kcal/s and heat dissipation from 0.48 to 2.33 kcal/s. The results of this theoretical study obtained through numerical calculations, the general trend of which is reduced to an increase in all the parameters under study depending on the decrease in the ambient air temperature , are in fairly good agreement with the research of scientists from near [19-22] and far [23] abroad. For subsequent substantiation of the numerical values, the obtained calculation data and the adequacy of the calculation models developed by the authors, it is necessary to conduct a series of laboratory and bench tests of thermodynamic processes in motor-axial bearings of traction electric motors of wheel-motor units of locomotives.

Also, numerical calculations have shown that the heating temperature of the lubricant in the surface layers in the friction zone of the motor-axial bearings with the journal of the wheelset axle, when the ambient temperature decreases, first “falls” (decreases) from 64.3 °C to 57.5 °C, and then, at subzero, negative temperatures, it begins to increase sharply and at the mentioned temperature = –38 °С approaches the critical flash point of the lubricant (oil) 130 °С [1].

In addition, the results of the theoretical studies presented served as a kind of prerequisite for the development of original designs of motor-axle bearings, ensuring increased efficiency [24] and operational reliability [25] of motor-axle bearings of serial-design locomotives in route of rolling stock.

4. Conclusions

Analysis of the results of this research to substantiate the influence of temperature and lubrication conditions in the contact zone of motor-axial bearings of traction electric motors of diesel locomotives with the journal of the axle of the wheelset on the heat transfer processes in them, taking into account the outside air temperature, allowed us to formulate the following general conclusions and proposals.

1) A calculated diagram of the motor-axial bearing and heat removal from the surface layer of lubricant to the neck of the wheelset axle has been developed.

2) A calculation scheme has been developed for heat removal from the surface layer of lubricant to the liner of the motor-axial bearing and to its middle layer.

3) At absolute maximum positive and negative values of the outside air temperature in the range of its decrease from +40 °С to –35 °С, viscosity, friction coefficient, heat generation and heat removal increase, respectively, in 833.33; 29.0; 36.85 and 4.85 times.

4) At negative (minus) temperatures of the outside (atmospheric) air, the heat release significantly, several times (approximately 7.6 times), exceeds the heat removal, creating the risk of overheating in the friction zone.

5) Numerical calculations prove (confirm) that at negative outside air temperatures of more than = –38 °С, the phenomenon of overheating of motor-axle bearings in the area of their contact with the neck of the wheelset axle is observed, which is caused by greatly increased viscosity and friction coefficient of the lubricant and, as a consequence, the heating temperature of the lubricant in the surface layers of the friction zone is equal to the critical flash point of the lubricant.

6) It is recommended to continue these studies in real conditions of organizing the operational activities of railways with locomotives of diesel tractions (diesel locomotives) in sections with varying degrees of difficulty.

Thus, studies of heat transfer processes in motor-axial bearings have shown that their operation is carried out in the semi-fluid friction mode, while the heat removal in them, especially at negative ambient temperatures, does not ensure their normal operation, and the share of heat removed by the lubricant is only approximately 1.5 percent, which leads to motor-axial bearings premature wear and their failure.

References

-

O. V. Melnichenko, Motor-Axial Bearings and Their Lubrication Systems on Modern Domestic Locomotives. Irkutsk: IrGUPS, 2009.

-

O. V. Melnichenko, N. L. Mikhalchuk, A. V. Dimov, and T. N. Melnichenko, “Development of a complex for automatic filling and diagnostics of axle boxes with a constant level of lubrication of motor-axial bearings of an electric locomotive,” Modern Technologies, System Analysis, Modeling, Vol. 3, No. 49, pp. 47–54, 2008.

-

K. Zhussupov, A. Toktamyssova, S. Abdullayev, G. Bakyt, and M. Yessengaliyev, “Investigation of the stress-strain state of a wheel flange of the locomotive by the method of finite element modeling,” Mechanics, Vol. 24, No. 2, pp. 174–181, May 2018, https://doi.org/10.5755/j01.mech.24.2.17637

-

A. S. Kushniruk, “Analysis of the reliability indicators of the motor-axle bearings of the locomotive wheel-motor unit at the operating site of the Far Eastern Railway,” Transport of the Asian Pacific Region, Vol. 3, No. 24, pp. 18–20, 2020.

-

O. S. Ablyalimov and D. O. Rajibaev, “Efficiency of transportation work of diesel locomotive Uzte16M3 series at the section of Uzbek railway,” in The 3rd International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2021 AS), Vol. 2612, p. 060011, Jan. 2023, https://doi.org/10.1063/5.0113222

-

O. Ablyalimov, “To the substantiation of charge air parameters on different operating modes of diesel engines of diesel locomotives,” in E3S Web of Conferences, Vol. 460, p. 06010, Dec. 2023, https://doi.org/10.1051/e3sconf/202346006010

-

O. S. Ablyalimov, “Methodology for assessing the efficiency of transportation works of locomotives under operating conditions,” ICTEA, Vol. 1, No. 1, Jan. 2024.

-

K. Yan, N. Wang, Q. Zhai, Y. Zhu, J. Zhang, and Q. Niu, “Theoretical and experimental investigation on the thermal characteristics of double-row tapered roller bearings of high speed locomotive,” International Journal of Heat and Mass Transfer, Vol. 84, pp. 1119–1130, May 2015, https://doi.org/10.1016/j.ijheatmasstransfer.2014.11.057

-

S. Abdullayev, G. Imasheva, N. Tomkurzina, N. Adilova, and G. Bakyt, “Prospects for the use of gondola cars on bogies of model zk1 in the organization of heavy freight traffic in the Republic of Kazakhstan,” Mechanics, Vol. 24, No. 1, pp. 32–36, Feb. 2018, https://doi.org/10.5755/j01.mech.24.1.17710

-

W. C. Tang, M. J. Wang, and G. D. Chen, “Analysis on temperature distribution of failure axle box bearings of high-speed train,” Journal of the China Railway Society, Vol. 38, No. 7, pp. 50–56, Jan. 2016.

-

D. X. Zheng and W. F. Chen, “Effect of structure and assembly constraints on temperature of high-speed angular contact ball bearings with thermal network method,” Mechanical Systems and Signal Processing, Vol. 145, p. 106929, 2020.

-

Y. Liu, B. Wang, B. Zhang, and S. Yang, “Establishment of dynamic model for axle box bearing of high-speed trains under variable speed conditions,” Chinese Journal of Mechanical Engineering, Vol. 35, No. 1, May 2022, https://doi.org/10.1186/s10033-022-00725-0

-

Z. Wang, Y. Cheng, P. Allen, Z. Yin, D. Zou, and W. Zhang, “Analysis of vibration and temperature on the axle box bearing of a high-speed train,” Vehicle System Dynamics, Vol. 58, No. 10, pp. 1605–1628, Oct. 2020, https://doi.org/10.1080/00423114.2019.1645340

-

S. A. Chernavsky, Sliding bearings. Moscow: Mashgiz, 1963.

-

M. O. Mussabekov, G. B. Bakyt, A. M. Omirbek, E. Brumerčíková, and B. Buková, “Shunting locomotives fuel and power resources decrease,” in MATEC Web of Conferences, Vol. 134, p. 00041, Nov. 2017, https://doi.org/10.1051/matecconf/201713400041

-

I. V. Kragelsky and I. E. Vinogradova, Friction Coefficients: a Reference Guide. Moscow: Mashgiz, 1992.

-

S. Abdullayev, N. Tokmurzina, and G. Bakyt, “The determination of admissible speed of locomotives on the railway tracks of the Republic of Kazakhstan,” Transport Problems, Vol. 11, No. 1, pp. 61–68, Jan. 2016, https://doi.org/10.20858/tp.2016.11.1.6

-

A. Glushchenko, M. Tashpoltaev, and O. Ablyalimov, “Methods of evaluating cotton harvesting machines,” Journal Khlopok, Vol. 69, No. 4, pp. 25–28, 1990.

-

N. G. Polyushkin, “Fundamentals of the theory of friction, wear and lubrication: textbook,” Krasnoyarsk State Agrarian University, Krasnoyarsk, 2013.

-

N. Z. Boyko, “Working fluids, lubricants and seals: a tutorial,” State Educational Institution of Higher Professional Education of the LPR DonSTU, Alchevsk, 2018.

-

V. M. Kapustin, D. Y. Makhin, L. A. Smirnova, and M. A. Ershov, Collection of Problems on Oil and Gas Processing Technology. Part I. Primary Oil Refining: Textbook. Moscow: Publishing center of the Gubkin Russian State University of Oil and Gas (National Research University), 2020.

-

N. V. Inozemtseva and S. I. Prach, Sliding Bearings and Their Calculation: Educational Method, Manual. Gomel: GGTU im. P. O. Sukhoi, 2023.

-

F. Pouly, C. Changenet, F. Ville, P. Velex, and B. Damiens, “Power loss predictions in high-speed rolling element bearings using thermal networks,” Tribology Transactions, Vol. 53, No. 6, pp. 957–967, Oct. 2010, https://doi.org/10.1080/10402004.2010.512117

-

A. D. Glushchenko et al., “Motor-axial bearing of locomotive,” SU 1239012 A1, 1986.

-

A. D. Glushchenko, A. P. Fedotov, S. A. Dolgikh, and O. S. Ablalimov, “Device for lubrication of motor-axle bearings of locomotive traction electric motors,” SU 1306783, 1987.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.