Abstract

The research conducted at the “Foundry and Mechanical Plant” JSC is devoted to the analysis of the influence of the temperature regime of pouring 20GL steel into molds on the formation of defects. It was experimentally established that the optimal range of pouring temperatures allows avoiding such defects as hot cracks and underfills. Data were obtained on the time of filling molds, the distribution of defects and the preservation of the metal structure at different temperatures. It was proven that compliance with the temperature range of 1580-1590 °C guarantees high quality castings. Based on the results of the study, technological parameters were proposed that ensure minimal formation of defects and uniform formation of the grain structure.

1. Introduction

The process of pouring liquid metal is one of the most important stages in the production of large cast parts, such as the side frames of freight wagons. Side frames play a key role in the construction of freight wagons, ensuring the transfer of loads from the body to the wheel pairs through the axle boxes, as well as the stability and reliability of the entire wagon. Their quality directly affects the operational characteristics of the rolling stock, which makes their production technology critically important. The production of side frames of freight wagons is a complex casting process that requires strict compliance with technological parameters at each stage. One of the most critical parameters is the pouring temperature of the liquid metal. This parameter determines the fluidity of the melt, the filling rate of the mold, the uniformity of its distribution and the subsequent microstructure of the casting. Failure to comply with the temperature regime can lead to a number of defects, such as hot cracks, underfilling, sinks and other structural disorders that reduce the strength characteristics and durability of the finished product. Special attention is paid to the casting temperature of 20GL steel, which is widely used in the production of side frames. This material is characterized by high strength and viscosity properties, which makes it suitable for large castings. However, the pouring process requires precise temperature control, since changing this parameter can lead to heterogeneity of the metal structure, grain growth and the occurrence of internal stresses.

The main purpose of this study is to analyze the influence of the pouring temperature on the quality of steel castings of the 20GL grade, identify the causes of defects and determine the optimal temperature parameters. The results of the work will improve the technological process, minimize the number of defects and increase productivity in the manufacture of side frames of freight wagons.

2. Theoretical foundations

Temperature pourings has an effect on the fluidity of liquid steel. As the temperature changes, the viscosity of the metal decreases, which contributes to a faster and more uniform filling of the mold. This is especially important for large castings, such as the side frames of freight wagons, where the width of the metal is critical to prevent defects. However, too high a temperature has its negative consequences.

Firstly, high temperature increases the gas saturation of the metal, since the molten metal better dissolves oxygen and hydrogen from the environment. This leads to the formation of gas pores and deterioration of the properties of the material. Secondly, high temperature leads to oxidation of the melt, which affects the formation of slag inclusions. This violates the density of the material, ensures the safety of weak points in the cast part. Thirdly, due to the increased crystallization time at high temperature, the motion processes become larger, which creates global stresses in the material.

3. Formation of the microstructure

Temperature fillings also determine the nature of crystallization and recrystallization of the metal.

Crystallization at high temperature. At temperatures above 1600 °C, large dendrites develop in areas with slow cooling. This structure of the structure demonstrates a pronounced heterogeneity of microstructures, leading to a decrease in enormous strength and an increase in brittleness.

Recrystallization at low temperature. At temperatures below 1570 °C, accelerated cooling ensures the formation of a fine-grained structure. This takes into account the caution of the material, but the risk of casting defects, such as underfilling or looseness, increases due to insufficient fluidity of the melt.

Thus, the choice of filling temperature determines not only the quality of filling the mold, but also the composition of the material. In order to achieve the original structure and prevent defects, strict temperature conditions must be observed. For 20GL steel, it is 1580-1590 °C, which ensures a balanced crystallization process and high quality castings.

4. Methods

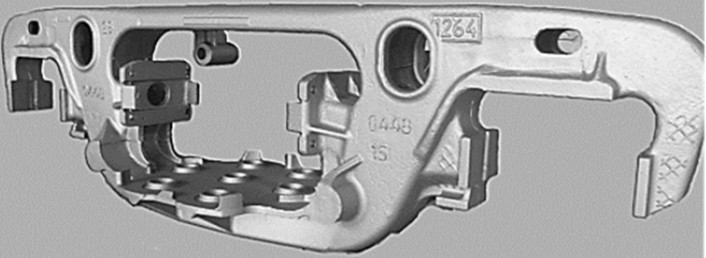

The object of the study: The side frames of freight wagons made of steel grade 20GL (Fig. 1).

Fig. 1Side frame (general view)

Molten metal from induction furnaces was transported in a ladle to an automated molding line. The study was conducted on an automated molding line at JSC Foundry and Mechanical Plant. 8 forms were filled at the same time. Temperature ranges: The studies were conducted at temperatures from 1560 to 1610 °C in increments of 10 °C. The time of filling out the form was fixed in each cycle.

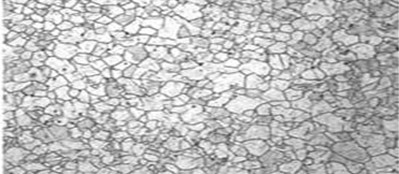

One of the important aspects of the production of large-sized castings, such as the side frames of freight wagons, is the control of the casting temperature of steel. Hot cracks are a serious defect that has arisen at the boundaries of crystalline grains. They not only reduce the strength of the product, but also make it vulnerable to fatigue loads. As shown in Fig. 2, hot cracks develop precisely in those zones where the intergranular bonds are not strong enough. The correct choice of the casting temperature allows you to avoid this, ensure a tighter connection of the grains and improve the properties of the cast part.

Fig. 2Features of the formation of hot cracks

a) The type of hot crack at the grain boundary

b) The type of structure in which no hot crack is observed

Thus, the casting temperature has a complex effect on the quality of the casting. The correct choice of temperature regime allows not only to avoid cracking, but also to ensure the stability of the grain structure, which increases the performance characteristics of the product. These results determine the degree of accurate temperature control for all casting criteria.

5. Results and discussion

5.1. Time to fill out the form

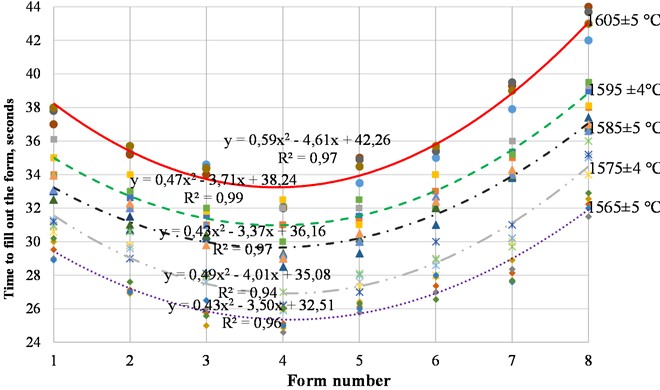

Fig. 3 shows how the filling temperature affects the filling time of the mold.

At a temperature of 1560-1570 °C, the mold filling time increases, which is due to the low fluidity of the melt. At 1580-1590 °C, the stabilization time ensures uniform distribution of the metal. At 1600 °C and above, keep the time to a minimum, however, increased fluidity leads to other defects such as hot cracks.

Fig. 3Graph of the dependence of the mold filling time on the volume of metal in the bucket at temperatures of 1560 °C-1610 °C for casting the side frame

5.2. Observed defects

When analyzing the pouring temperature of the casting quality, clear patterns were identified that determine the optimal process parameters.

Table 1Summary information on defects at different pouring temperatures is presented

Pouring temperature °C | Form number | |||||||

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

1565±5 | – | – | – | – | – | – | Looseness | Underfilling |

1575±4 | – | – | – | – | – | – | Looseness | – |

1585±5 | – | – | – | – | – | – | – | – |

1595 ±4 | – | – | – | – | Hot crack | – | – | – |

1605±5 | – | – | – | Hot crack | Hot crack | Hot crack | – | – |

At high pouring temperatures exceeding 1600 °C, hot cracks were observed in the intermediate molds (third, fourth and fifth). This defect leads to the occurrence of a temperature gradient inside the metal. Slow cooling at such temperatures causes significant stresses, which cause the destruction of materials along the boundaries of crystal grains.

On the other hand, the required pouring temperature of less than 1560 °C leads to problems with filling the mold. In the molds (seventh and eighth), defects were recorded such as underfilling associated with incomplete filling of the mold, and surface roughness caused by insufficient fluidity of the last melt. These defects reduce the quality of the casting surface.

The optimum temperature range for pouring grade 20GL steel is between 1570 and 1590 °C. In this respect, uniform filling of the mold with liquid metal is ensured, internal stress is minimized, and the structure of the material becomes external. All molds cast at these temperatures were free of defects.

Grain structure measurement also provides the influence of the pouring temperature. At 1600 °C, slow cooling leads to uneven grain formation. Large particles are formed in areas with slow cooling, whereas small particles were observed in areas with fast cooling. This leads to structural heterogeneity and a potentially weak spot in the cast part. At temperatures below 1560 °C, the cooling process is too fast, which leads to the formation of a fine-grained structure. However, casting defects such as underfilling and roughness continue to have a negative impact on quality. Depending on the temperature of 1580-1590 °C, clothing protects a uniform structure with a uniform grain distribution. This structure provides enhanced mechanical properties, including strength, ductility and fatigue resistance. The higher the casting temperature, the higher the metal fluidity. This reduces the time to take shape, but constantly leads to saturation of metals with gases, increased oxidation and the formation of defects such as hot cracks. The optimal temperature range of 1580-1590 °C avoids these problems, ensures high-quality mold filling and minimizes casting defects. Thus, the established casting parameters can be considered the most suitable for the production of large-sized castings made of 20GL steel, such as the side frames of freight wagons. This ensures the absence of defects and expansion of the structural material while observing the recommended temperatures.

6. Conclusions

The results obtained have practical application in industry. The established filling temperature range (1570-1590 °C) can be implemented in the technological process of production of side frames of freight wagons. This will allow: to reduce the number of defective castings, reduce production costs, and improve the performance of foundry castings. Practical recommendations: moderate casting temperature of 20GL steel, to prevent the formation of cracks and underfilling, take into account the temperature of the grain size to improve the mechanical properties of castings.

References

-

O. Toirov and N. Tursunov, “Development of production technology of rolling stock cast parts,” in E3S Web of Conferences, Vol. 264, p. 05013, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405013

-

M. Turakulov, N. Tursunov, and S. Yunusov, “Steeling of synthetic cast iron in induction crucible furnace taking into account consumption rate of carburizers,” in E3S Web of Conferences, Vol. 401, p. 05012, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105012

-

U. T. Rakhimov, N. K. Tursunov, and S. E. Tursunov, “Improvement of production technology for spheroidal graphite cast iron with increased strength,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060024, Jan. 2024, https://doi.org/10.1063/5.0197475

-

N. K. Tursunov, A. E. Semin, and E. A. Sanokulov, “Study of dephosphoration and desulphurization processes in the smelting of 20GL steel in the induction crucible furnace with consequent ladle treatment using rare earth metals,” Chernye Metally, No. 1, pp. 33–40, Jan. 2017.

-

O. Toirov, N. Tursunov, S. Alimukhamedov, and L. Kuchkorov, “Improvement of the out-of-furnace steel treatment technology for improving its mechanical properties,” in E3S Web of Conferences, Vol. 365, p. 05002, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505002

-

L. Kuchkorov, S. Alimukhamedov, N. Tursunov, and O. Toirov, “Effect of different additives on the physical and mechanical properties of liquid-glass core mixtures,” in E3S Web of Conferences, Vol. 365, p. 05009, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505009

-

O. Toirov and N. Tursunov, “Efficiency of using heat-insulating mixtures to reduce defects of critical parts,” in E3S Web of Conferences, Vol. 401, p. 05018, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105018

-

Z. Mukhamedova, “Determination methods of factors affecting piggyback transportation,” Civil Engineering and Architecture, Vol. 12, No. 1, pp. 121–132, Jan. 2024, https://doi.org/10.13189/cea.2024.120110

-

Z. Mukhamedova Gafurdjanovna, S. Fayzibayev Sabirovich, D. Mukhamedova Gafurdjanovna, G. Ibragimova Ruslanovna, and S. Kayumov Sharof Ogli, “Appraisal Reliability of Electromechanical Equipment of Rail Service Car,” Communications – Scientific letters of the University of Zilina, Vol. 26, No. 2, pp. B108–B117, Apr. 2024, https://doi.org/10.26552/com.c.2024.021

-

S. Azimov, O. Toirov, B. Xalmurzayev, S. Tursunov, and K. Khujakhmedova, “Using a cooling hole to improve the performance of transport brakes,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060016, Jan. 2024, https://doi.org/10.1063/5.0197365

-

T. Tursunov, N. Tursunov, and T. Urazbayev, “Investigation of heat exchange processes in the lining of induction furnaces,” in E3S Web of Conferences, Vol. 401, p. 05029, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105029

-

M. Turakulov, N. Tursunov, and S. Yunusov, “New concept of cast iron melting technology in induction crucible furnace,” in E3S Web of Conferences, Vol. 401, p. 01060, Jul. 2023, https://doi.org/10.1051/e3sconf/202340101060

-

D. Valieva, S. Yunusov, and N. Tursunov, “Study of the operational properties of the bolster of a freight car bogie,” in E3S Web of Conferences, Vol. 401, p. 05017, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105017

-

L. Kuchkorov, N. Tursunov, and A. Avdeeva, “Improving physical and mechanical properties of bentonite clay from Navbahar clay deposit,” in E3S Web of Conferences, Vol. 401, p. 05020, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105020

-

U. Rakhimov and N. Tursunov, “Development of technology for high-strength cast iron for manufacturing D49 head of cylinder,” in E3S Web of Conferences, Vol. 401, p. 05013, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105013

-

T. Urazbayev, N. Tursunov, and T. Tursunov, “Steel modification modes for improving the cast parts quality of the rolling stock couplers,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060015, Jan. 2024, https://doi.org/10.1063/5.0197361

-

S. R. Seydametov, N. K. Tursunov, and S. P. Alimukhamedov, “Development of out-of-furnace steel treatment technology for the manufacture of railroad transport parts,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060022, Jan. 2024, https://doi.org/10.1063/5.0197429

-

M. Alimov, A. Riskulov, and K. Nurmetov, “Choosing of rational periodicity of engine crankcase oil changing taking into account energy-saving properties of oils,” in E3S Web of Conferences, Vol. 401, p. 05021, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105021

-

A. Riskulov, K. Nurmetov, and J. Avliyokulov, “Material selection for vehicle brake chamber case with using computer methods of analysis,” in E3S Web of Conferences, Vol. 401, p. 02061, Jul. 2023, https://doi.org/10.1051/e3sconf/202340102061

-

E. S. Taranova and V. V. Komissarov, “Regularities of influence of operating factors on friction and wear characteistics at rolling,” Journal of Friction and Wear, Vol. 34, No. 2, pp. 142–146, May 2013, https://doi.org/10.3103/s106836661302013x

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.