Abstract

The paper examines the problems of traditional sand-clay mixtures (SСM) used in steel castings and proposes solutions. Standard compositions including quartz sand, water and bentonite often exhibit limited gas permeability and insufficient strength. To address this, starch and soda ash were introduced as environmentally friendly additives. The scientific novelty of this research lies in the use of starch and soda ash to enhance the binding structure of sand-clay mixtures, thereby simultaneously improving strength and gas permeability without increasing production costs. Experimental analysis confirmed improvements in compressive strength and gas permeability, making the proposed mixture promising for industrial applications.

1. Introduction

The production of side frames of freight wagons is a complex casting process in which the choice of molding mixture is critically important. The foundry industry is faced with the need to develop resource-saving technologies that will increase the strength of molds while reducing material costs. In this paper, the development of new compositions of sand-clay mixtures (SСM) used in the manufacture of steel castings from 20GL is considered. SСM is one of the most common materials for the manufacture of molds. This material provides the necessary gas permeability, strength and shape stability, which makes it the optimal choice for casting large-sized parts such as side frames. Traditional sand-clay mixtures (SСM), widely used in the foundry industry, are the basis for the manufacture of molds, however, they have a number of disadvantages. In standard formulations, including quartz sand, water and bentonite, insufficient gas permeability and low strength are often observed. These factors limit the use of such mixtures for complex steel castings, especially large and critical parts, such as the side frames of freight wagons made of 20GL steel. The side frames of freight wagons perform an important constructive function, distributing the load from the body to the wheel pairs through the axle boxes. The quality and reliability of these parts directly depend on the characteristics of the mold, including its strength, stability and ability to remove gases during the pouring of liquid metal. Disadvantages of the traditional composition of SСM can lead to the formation of defects such as hot cracks, underflows and burns.

The purpose of this study is to develop a resource-saving composition of SСM with improved physico-chemical properties. To do this, modifying additives were introduced into the mixture: starch, which enhances the binding properties and improves the structure of the mixture. soda ash, which stabilizes the properties of bentonite and increases gas permeability.

As part of the work, measurements of the gas permeability of the mixture and its compressive strength were carried out. The results obtained made it possible to determine the optimal composition parameters that ensure an improvement in the quality of molds and an increase in the performance characteristics of steel castings.

2. Research methodology

To achieve the set goals and evaluate the effectiveness of the proposed resource-saving composition of the sand-clay mixture (SСM), a research methodology was developed, including the preparation of experimental samples and conducting tests on key characteristics. The initial composition of the mixture (quartz, bentonite and water) was compared with an improved composition, to which starch and soda ash were added. The main evaluation parameters included gas permeability, humidity and strength characteristics of the mold.

The process of preparing the studied compositions of the sand-clay mixture (SСM) included several successive stages aimed at obtaining a mass with improved physical and mechanical characteristics. The initial composition included quartz sand, bentonite and water. To modify the traditional mixture, additives were introduced: starch (1.5-2 % of the total mass of the mixture) and soda ash (0.5-1 %). These components were used to increase the binding characteristics, improve the structure of the mixture, stabilize the properties of bentonite and increase gas permeability, which is especially important for the production of large-sized steel castings.

3. Testing methods

The composition of the tested mixture has been selected for analysis and is shown in Table 1.

Table 1Composition of the tested mixtures

Composition | Traditional mixture (%) | Modified mixture (%) |

Quartz sand | 93 | 90 |

Bentonite | 7 | 7 |

Starch | – | 2 |

Calcined soda | – | 1 |

Water | 6 | 7 |

In order to evaluate the properties of the prepared mixtures, the following tests were carried out:

Compressive strength. The strength characteristics were determined on PVC pressing equipment (Fig. 1). Standard cylindrical samples with a diameter of 50 mm and a height of 50 mm (Fig. 2) were used for compression. The results obtained were recorded in megapascals (MPa).

Fig. 1PVF-C mini laboratory equipment for testing the molding mixture

Fig. 2Samples 50 x 50 mm for testing

Gas permeability. The gas permeability index was measured on the Simpson PED-D minilaboratory equipment for the study of molding mixtures (Fig. 3). Air was passed through a cylindrical sample, and the results were expressed in conventional units, allowing a comparative analysis of traditional and modified formulations.

Fig. 3Simpson PED-D electric device for determining the gas permeability of molding mixtures

The humidity of the mixture. The humidity of the mixture was determined by thermogravimetric analysis on the PWG MA35M device (Fig. 4). The samples were dried at a temperature of 105-110 °C to a constant mass. The mass loss was calculated using the formula:

where is the mass of the sample before drying, is the mass after drying.

The technique allowed to obtain detailed information about the properties of the mixture, including strength, gas permeability and humidity, which provided the basis for further analysis and optimization of the composition of the SСM.

Fig. 4Mini laboratory device PWG MA35M for determining the moisture content of the molding mixture.

4. Analysis of the results

1) The addition of starch increases the binding capacity of the mixture, which increases the strength.

2) Soda ash reduces bentonite content, which improves gas permeability and prevents defects such as hot cracks.

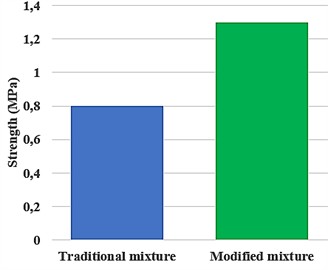

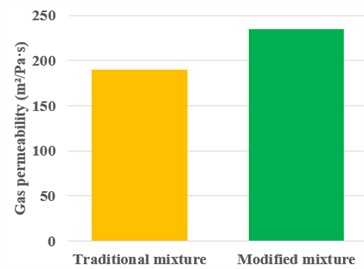

Table 2 shows the results of a comparative analysis of the mixtures tested.

Table 2The results of the comparative analysis of the tested mixtures

Parameter | Traditional mixture | Modified mixture |

Gas permeability, m2/Pa∙s | 190 | 235 |

Strength, MPa | 1 | 1.3 |

The experimental results demonstrated a clear enhancement in the physical properties of the sand-clay mixture when modified with starch and soda ash additives. These improvements were quantified by evaluating gas permeability and compressive strength under controlled laboratory conditions.

Firstly, the compressive strength of the modified mixture increased by 30 %, rising from 1.0 MPa to 1.3 MPa. This indicates a more coherent structure and improved binding capacity of the mixture due to the starch additive. The role of starch as a biodegradable binder is critical here, as it contributes to strengthening the microstructure of the mold without compromising its gas permeability.

Secondly, gas permeability improved significantly – from 190 to 235 m2/Pa·s, which corresponds to a 24 % increase. This is especially important for large and complex castings such as 20GL steel side frames, where insufficient gas escape can lead to casting defects like gas porosity, hot tears, and surface blemishes. The introduction of soda ash appears to enhance the activation of bentonite clay particles, improving pore connectivity and uniformity throughout the mold.

In addition to these numerical improvements, it was observed that the modified mixture provided more uniform moisture distribution. This reduced the occurrence of localized dry or overly moist zones, which typically lead to dimensional instability or defects during pouring and solidification. Furthermore, statistical analysis across multiple replicates (3) showed consistency in results, with standard deviations of ±0.03 MPa for strength and ±5 m2/Pa·s for gas permeability. This indicates good repeatability and reliability of the new composition. The performance results of the modified mixture therefore confirm its potential for industrial application, offering improved strength, enhanced gas permeability, and reduced likelihood of casting defects – all critical parameters for high-quality steel casting molds. These findings support the viability of using modified SCMs as a sustainable, cost-effective alternative to traditional molding materials in modern foundry practice

The proposed composition of the SСM made it possible to improve the physico-mechanical properties of the molding mixture, which is proposed in Fig. 5.

Strength increased by 25-30 %.

Gas permeability improved by 24 %.

This ensures high quality of 20GL alloy steel castings and cost reduction.

Fig. 5 illustrates that the proposed composition significantly exceeds the traditional one in all parameters, while the proposed composition changes have a positive effect on the properties of the casting mixture.

Fig. 5The results of a comparative analysis of the traditional and modified mixture.

a) Mixture strength of formulations

b) Gas permeability of mixtures

5. Conclusions

The conducted research confirmed that the introduction of starch and soda ash into the traditional sand-clay mixture leads to a notable improvement in the physical and mechanical properties of molding materials. The compressive strength of the modified mixture increased by up to 30 %, while gas permeability improved by approximately 24 %, demonstrating a direct enhancement of both structural coherence and gaseous exchange capacity within the mold. These improvements are especially relevant in steel casting production where casting defects are often linked to insufficient gas removal and low mold strength. The use of starch as a biodegradable binder enhances cohesion within the mold matrix, while soda ash contributes to the activation of bentonite, leading to better structural stability. Importantly, the scientific novelty of this research lies in the application of environmentally friendly additives (starch and soda ash) that simultaneously optimize critical properties of the sand-clay mixture without increasing production costs. This makes the modified mixture particularly attractive for resource-saving and energy-efficient applications.

Given the constraints typically observed in limited-capability foundry environments, such as small-scale steel casting workshops in developing regions, the proposed composition offers a cost-effective and technologically feasible solution. The simplicity of implementation and the availability of additives ensure that the new formulation can be integrated even in constrained industrial settings. Thus, the results open up new opportunities for sustainable development of casting technologies, especially in facilities where advanced additives or automation are not readily accessible. The modified SCM composition may serve as a foundation for further research aimed at improving casting reliability, reducing defect rates, and promoting greener production practices in metallurgy.

References

-

O. Toirov and N. Tursunov, “Development of production technology of rolling stock cast parts,” in E3S Web of Conferences, Vol. 264, p. 05013, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405013

-

M. Turakulov, N. Tursunov, and S. Yunusov, “Steeling of synthetic cast iron in induction crucible furnace taking into account consumption rate of carburizers,” in E3S Web of Conferences, Vol. 401, p. 05012, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105012

-

U. T. Rakhimov, N. K. Tursunov, and S. E. Tursunov, “Improvement of production technology for spheroidal graphite cast iron with increased strength,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060024, Jan. 2024, https://doi.org/10.1063/5.0197475

-

N. K. Tursunov, A. E. Semin, and E. A. Sanokulov, “Study of dephosphoration and desulphurization processes in the smelting of 20GL steel in the induction crucible furnace with consequent ladle treatment using rare earth metals,” Chernye Metally, Vol. 2017, No. 1, pp. 33–40, 2017.

-

O. Toirov, N. Tursunov, S. Alimukhamedov, and L. Kuchkorov, “Improvement of the out-of-furnace steel treatment technology for improving its mechanical properties,” in E3S Web of Conferences, Vol. 365, p. 05002, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505002

-

L. Kuchkorov, S. Alimukhamedov, N. Tursunov, and O. Toirov, “Effect of different additives on the physical and mechanical properties of liquid-glass core mixtures,” in E3S Web of Conferences, Vol. 365, p. 05009, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505009

-

S. Azimov, O. Toirov, B. Xalmurzayev, S. Tursunov, and K. Khujakhmedova, “Using a cooling hole to improve the performance of transport brakes,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060016, Jan. 2024, https://doi.org/10.1063/5.0197365

-

Z. Mukhamedova, “Determination methods of factors affecting piggyback transportation,” Civil Engineering and Architecture, Vol. 12, No. 1, pp. 121–132, Jan. 2024, https://doi.org/10.13189/cea.2024.120110

-

Z. Mukhamedova Gafurdjanovna, S. Fayzibayev Sabirovich, D. Mukhamedova Gafurdjanovna, G. Ibragimova Ruslanovna, and S. Kayumov Sharof Ogli, “Appraisal reliability of electromechanical equipment of rail service car,” Communications – Scientific letters of the University of Zilina, Vol. 26, No. 2, pp. B108–B117, Apr. 2024, https://doi.org/10.26552/com.c.2024.021

-

T. Tursunov, N. Tursunov, and T. Urazbayev, “Investigation of heat exchange processes in the lining of induction furnaces,” in E3S Web of Conferences, Vol. 401, p. 05029, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105029

-

M. Turakulov, N. Tursunov, and S. Yunusov, “New concept of cast iron melting technology in induction crucible furnace,” in E3S Web of Conferences, Vol. 401, p. 01060, Jul. 2023, https://doi.org/10.1051/e3sconf/202340101060

-

O. Toirov and N. Tursunov, “Efficiency of using heat-insulating mixtures to reduce defects of critical parts,” in E3S Web of Conferences, Vol. 401, p. 05018, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105018

-

D. Valieva, S. Yunusov, and N. Tursunov, “Study of the operational properties of the bolster of a freight car bogie,” in E3S Web of Conferences, Vol. 401, p. 05017, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105017

-

L. Kuchkorov, N. Tursunov, and A. Avdeeva, “Improving physical and mechanical properties of bentonite clay from Navbahar clay deposit,” in E3S Web of Conferences, Vol. 401, p. 05020, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105020

-

U. Rakhimov and N. Tursunov, “Development of technology for high-strength cast iron for manufacturing D49 head of cylinder,” in E3S Web of Conferences, Vol. 401, p. 05013, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105013

-

T. Urazbayev, N. Tursunov, and T. Tursunov, “Steel modification modes for improving the cast parts quality of the rolling stock couplers,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060015, Jan. 2024, https://doi.org/10.1063/5.0197361

-

S. R. Seydametov, N. K. Tursunov, and S. P. Alimukhamedov, “Development of out-of-furnace steel treatment technology for the manufacture of railroad transport parts,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060022, Jan. 2024, https://doi.org/10.1063/5.0197429

-

M. Alimov, A. Riskulov, and K. Nurmetov, “Choosing of rational periodicity of engine crankcase oil changing taking into account energy-saving properties of oils,” in E3S Web of Conferences, Vol. 401, p. 05021, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105021

-

A. Riskulov, K. Nurmetov, and J. Avliyokulov, “Material selection for vehicle brake chamber case with using computer methods of analysis,” in E3S Web of Conferences, Vol. 401, p. 02061, Jul. 2023, https://doi.org/10.1051/e3sconf/202340102061

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.