Abstract

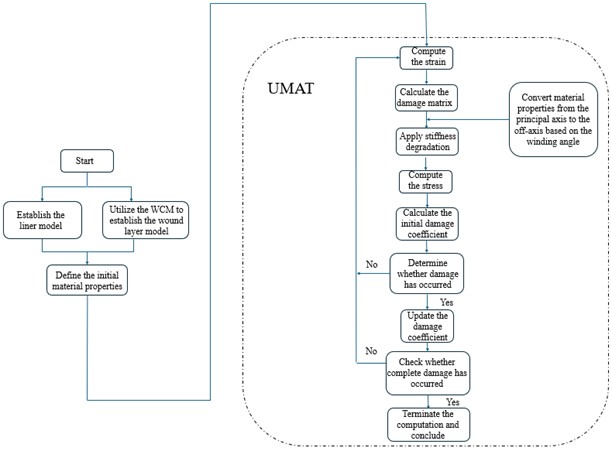

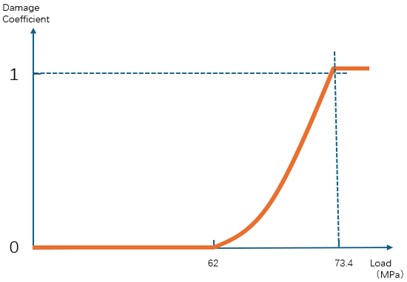

In addressing the issue of continuous damage evolution and failure prediction in composite pressure vessels, this paper combines the three-dimensional Hashin criterion with the equivalent displacement method to develop a static damage identification and progressive evolution model capable of accurately simulating material stiffness degradation under complex loading conditions. To validate the proposed model, carbon fiber/epoxy composite pressure vessels were used as the research subject. The UMAT subroutine, coupled with the Wound Composite Model (WCM) plugin, was employed to transform the principal material properties into off-axis properties and to establish the static damage identification and progressive evolution model for composite pressure vessels. Simulation results indicate that the vessel enters an initial damage state at an internal pressure of 62 MPa, with damage continuously evolving as the internal pressure increases, ultimately resulting in complete failure at 73.4 MPa. This model effectively simulates the entire process of damage initiation, propagation, and ultimate failure under internal pressure loading.

Highlights

- Three-dimensional Hashin criterion combined with the equivalent displacement method to construct a static damage identification and asymptotic evolution model

- Conversion of composite material principal axis properties to off-axis properties is accomplished by UMAT in conjunction with the WCM (Wound Composite Model) plug-in.

- The model can well simulate the whole process of damage under internal pressure loading, from the emergence to the expansion until the final failure.

1. Introduction

Composite pressure vessels have been widely used in aerospace, energy, and other fields due to their high specific strength, lightweight nature, and excellent corrosion resistance. Their internal damage evolution exhibits multiscale characteristics-such as micro-crack initiation, fiber breakage, and matrix fracture-that directly impact structural safety and design optimization.

Traditional three-dimensional progressive failure models, such as the strength reduction degradation model proposed by Camanho and Matthews [1], reduce the failure modes for fiber tension, compression, and matrix tension, compression through different parameters. Although these models can effectively predict failure and ensure convergence in finite element analyses, they do not accurately capture the true damage evolution process in composite materials.

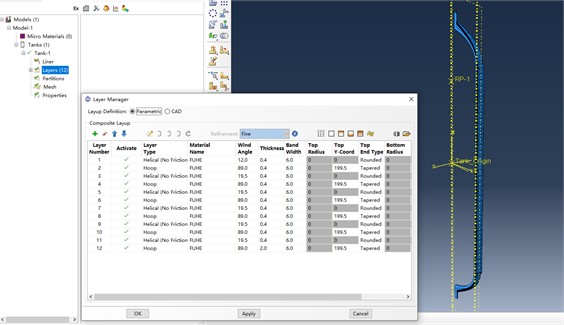

To address this limitation, this paper develops a static damage identification and progressive evolution model based on continuum damage mechanics. Implemented via a UMAT subroutine, the model adopts the three-dimensional Hashin criterion as the damage initiation standard and integrates the equivalent displacement method to simulate the entire damage evolution process. This approach provides a robust theoretical foundation and a practical tool for the static performance analysis, optimization design, and safety assessment of carbon fiber/epoxy composite pressure vessels.

2. Mathematical model

2.1. Theoretical fundamentals of composite material mechanics

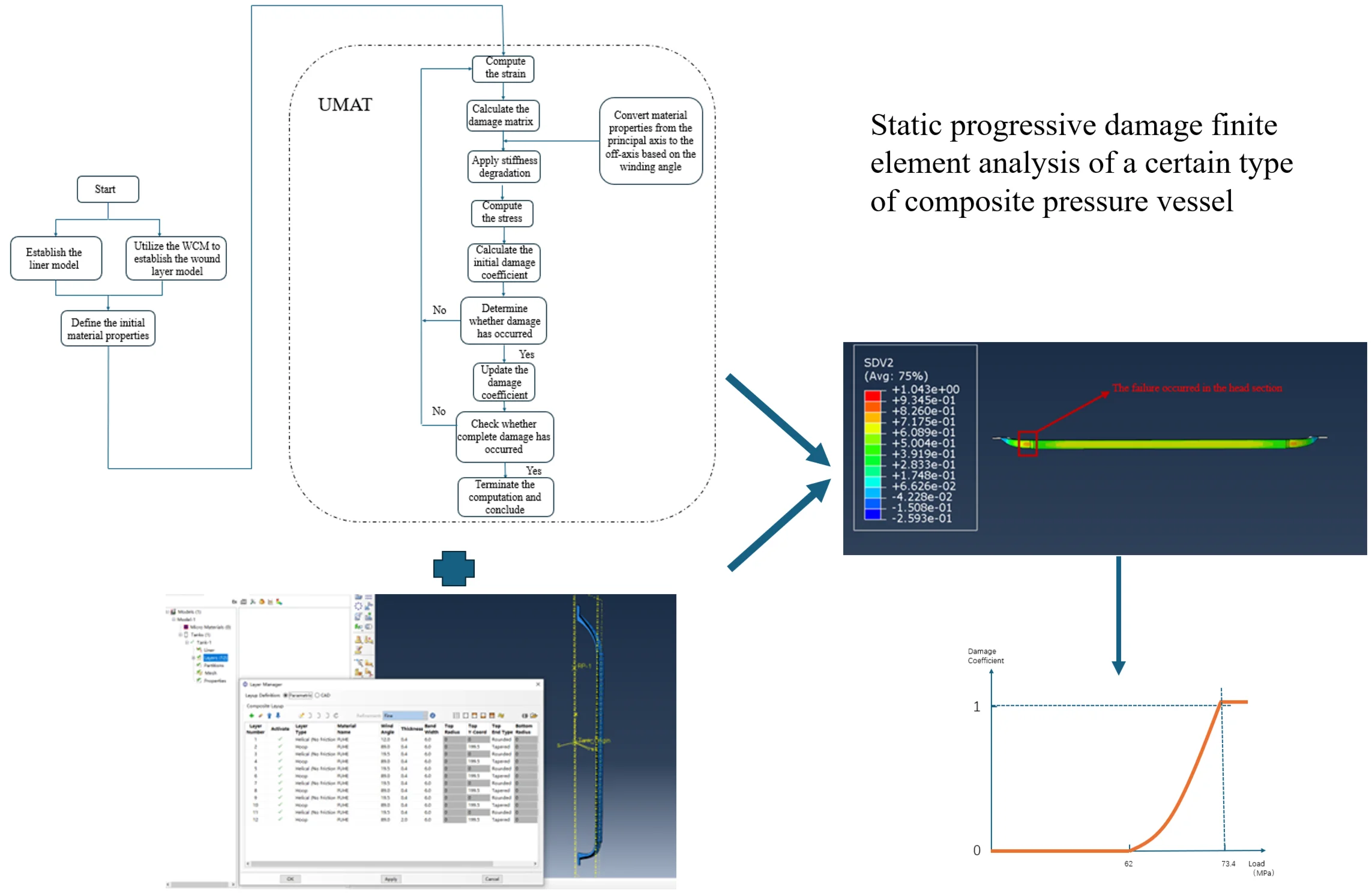

The carbon fiber winding layer is composed of carbon fibers and a resin matrix, exhibiting significant anisotropy. The constitutive equation is used to represent the stress–strain relationship of the material under external loads, thereby enabling the prediction of stress distribution, deformation, and failure mechanisms. In the stress calculation and strength verification of the winding layer, the overall stiffness distribution must first be determined. The principal material parameters are converted into off-axis parameters using the windangle function provided by the WCM plugin [2] (as shown in Fig. 1, where and denote the off-axis directions and represents the angle between the -axis and direction 1). This conversion is then used to compute the constitutive equation, thus providing a more accurate description of the mechanical characteristics of the winding layer [3].

Fig. 1Schematic diagram of the transformation between off-axis and principal axes

The transformation relationship for principal stress and strain is:

The transformation relationship for off-axis stress and strain [3] is given by :

where:, , is the material’s principal stiffness matrix.

2.2. Damage initiation criterion

The carbon fiber composite layer is the primary load-bearing component of the pressure vessel, and its damage model can be divided into intra-laminar damage (such as failure of fibers and matrix under tension or compression) and interlaminar damage. In the analysis, composite materials can be simplified as orthotropic materials to focus on overall structural failure while neglecting internal damage. In 1980, Japanese scholars proposed the Hashin criterion as an empirical method, treating composite materials as a multi-layer assembly and considering multiple failure modes, including fiber breakage, matrix failure, and shear failure [5].

Fiber Tension :

Fiber Compression :

Matrix Tension :

Matrix Compression :

2.3. Damage evolution criterion

After damage initiation, a progressive stiffness degradation model based on the studies by Lapczyk [5] and Fang [6] is employed in conjunction with Murakami’s damage theory [7] to analyze the evolution of damage. In this model, independent damage variables are defined for each failure mode, and the material degradation process is characterized by a continuous reduction in stiffness. For each failure mode, the damage variable can be expressed as:

where is the equivalent displacement at final failure, is the equivalent displacement at damage initiation, and current is the equivalent displacement at the current analysis step.

2.4. Construction of the static damage identification and progressive evolution model based on the three-dimensional Hashin criterion and equivalent displacement method

The static damage identification and progressive evolution model developed in this study is implemented in three stages. First, a mapping relationship between the finite element and the windangle data is established, and the material parameters in the principal direction are converted into off-axis parameters to compute the constitutive equation. Next, the stress is calculated using the constitutive equation, and damage indices such as fiber tension are computed based on the three-dimensional Hashin criterion. When any one of these indices reaches the critical value of 1, the material is considered to have entered the initial stage of damage evolution. Finally, during the evolution phase, the damage coefficient is calculated using the equivalent displacement method, and a damage matrix is constructed to achieve a gradual degradation of the winding layer’s stiffness, thereby fully describing the entire process of the composite material transitioning from an undamaged to a damaged state:

3. Finite element modeling

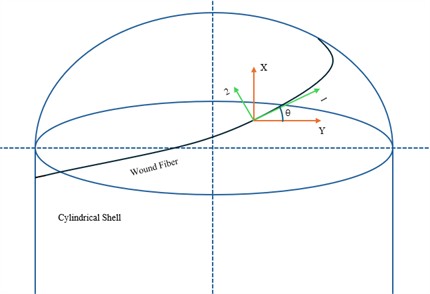

To validate the theoretical accuracy, this study employed the liner structural data and winding layer layup scheme proposed by Zuo Qian in [10]. By integrating the geometric features of the gas cylinder with the WCM plugin, a 1/36 model of the composite pressure vessel was constructed using C3D8R solid elements. The WCM (Wound Composite Modeler plug-in) is a specialized fiber-winding composite material modeling tool developed by Dassault Systèmes on the ABAQUS platform.

Fig. 2Inner liner dimensions of the pressure vessel [9]

![Inner liner dimensions of the pressure vessel [9]](https://static-01.extrica.com/articles/24890/24890-img2.jpg)

Fig. 3WCM lamination scheme

The aluminum liner is made of 6061 aluminum alloy. The carbon fiber composite layer is the final product obtained by wet winding T700 carbon fibers with epoxy resin followed by a curing process. The material properties of the T700/M21 carbon fiber composite layer used in this study are provided in Table 1.

Table 1Material properties of the T700/M21 composite layer

Properties | Values |

Density (Kg/m3) | 1600 |

Elastic modulus (GPa) | 45.68, 10.68 |

Shear modulus (GPa) | 3.7, 4.25 |

Poisson’s ratio | 0.29, 0.33 |

Strength (MPa) | 2080, 1250, 60, 140, 110 |

4. Finite element analysis of the progressive damage model for composite pressure vessels

On the ABAQUS/Standard platform, a static progressive damage model for the composite layer was developed using a UMAT subroutine programmed in FORTRAN. Based on the 1/36 model structure, cyclic symmetry, tie constraints, circumferential symmetry constraints, and a uniformly distributed pressure load on the liner wall were applied. Fig. 4 illustrates the numerical implementation process of this model.

4.1. Damage process analysis

A stepwise loading approach with increments of 1 MPa was used to simulate over-designed burst conditions: initial damage occurs when the internal pressure reaches 62 MPa, with the damage coefficient increasing nonlinearly from zero as the pressure rises; when the pressure increases to 73.4 MPa, the damage coefficient reaches 1, indicating complete structural failure. Fig. 6 illustrates the trend of the damage variable as a function of internal pressure.

Fig. 4Flowchart of the computational process

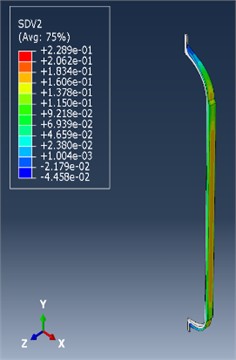

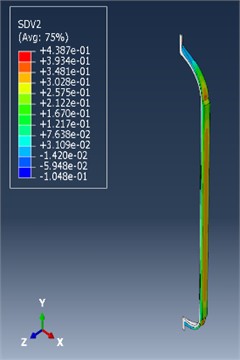

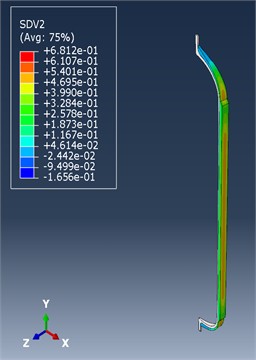

Fig. 5Damage evolution process of the pressure vessel under high-intensity loading

Fig. 6Damage variable trend graph

4.2. Ultimate burst pressure prediction

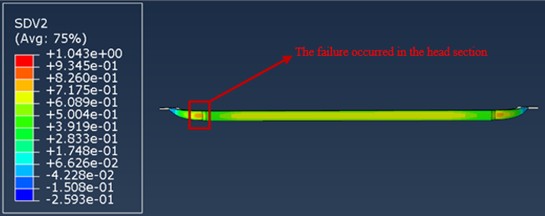

Numerical simulations indicate that the vessel experiences complete failure at an internal pressure of 73.4 MPa, with the failure primarily concentrated in the head region. The simulation results are in excellent agreement with experimental data, thereby verifying the accuracy of the model.

Fig. 7Failure location prediction

5. Conclusions

This study developed a static damage identification and progressive evolution model that elucidates the damage evolution mechanism of carbon fiber/epoxy composite pressure vessels under internal pressure. The findings reveal that, due to stress concentration, the head section becomes the initial region of failure, and the fiber winding angle plays a crucial role in regulating the damage propagation path and overall vessel strength. Optimizing the winding angle can effectively delay damage accumulation and enhance the load-bearing capacity.

References

-

M. Ahmadi Jebeli and M. Heidari-Rarani, “Development of Abaqus WCM plugin for progressive failure analysis of type IV composite pressure vessels based on Puck failure criterion,” Engineering Failure Analysis, Vol. 131, p. 105851, Jan. 2022, https://doi.org/10.1016/j.engfailanal.2021.105851

-

P. Liu, “Mechanical performance of composite gas cylinders under different winding processes,” (in Chinese), Dalian University of Technology, Dalian, China, 2017.

-

X. Wu, “Design and numerical simulation study of carbon fiber reinforced pressure vessels,” (in Chinese), Zhejiang University of Science and Technology, Hangzhou, China, 2023.

-

Z. Hashin, “Failure criteria for unidirectional fiber composites,” Journal of Applied Mechanics, Vol. 47, No. 2, pp. 329–334, Jun. 1980, https://doi.org/10.1115/1.3153664

-

I. Lapczyk and J. A. Hurtado, “Progressive damage modeling in fiber-reinforced materials,” Composites Part A: Applied Science and Manufacturing, Vol. 38, No. 11, pp. 2333–2341, Nov. 2007, https://doi.org/10.1016/j.compositesa.2007.01.017

-

G. D. Fang, J. Liang, and B. L. Wang, “Progressive damage and nonlinear analysis of 3D four-directional braided composites under unidirectional tension,” Composite Structures, Vol. 89, No. 1, pp. 126–133, Jun. 2009, https://doi.org/10.1016/j.compstruct.2008.07.016

-

G. Alfano and E. Sacco, “Combining interface damage and friction in a cohesive‐zone model,” International Journal for Numerical Methods in Engineering, Vol. 68, No. 5, pp. 542–582, Oct. 2006, https://doi.org/10.1002/nme.1728

-

O. H. Hassoon, M. Tarfaoui, and A. El Moumen, “Progressive damage modeling in laminate composites under slamming impact water for naval applications,” Composite Structures, Vol. 167, pp. 178–190, May 2017, https://doi.org/10.1016/j.compstruct.2017.02.004

-

Q. Zuo, “Study on burst pressure and optimization design of filament wound composite pressure vessels,” (in Chinese), Zhejiang University, Hangzhou, China, 2022.

-

C. Wang, “Structural design and forming process study of Type IV carbon fiber composite pressure vessels,” (in Chinese), Hefei University of Technology, Hefei, China, 2022.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.