Abstract

The article discusses the improvement of the technology of heat treatment of springs made of structural spring-spring steel grade 55Si2, used in rolling stock of railway transport. The authors conducted extensive experiments to study the effect of different temperatures and duration of heat treatment on the mechanical properties of springs. During the research, optimal quenching and tempering modes were identified, which significantly improved the strength characteristics, wear resistance and stability of the springs. The results of the work formed the basis of new technological instruction aimed at improving the quality and increasing the yield of usable products, which is important for improving the reliability of freight wagons operation.

1. Introduction

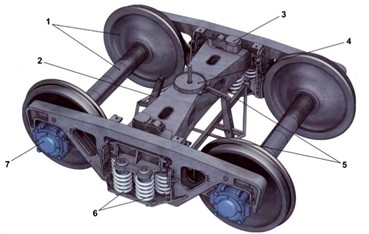

To mitigate the impacts that occur when the wheel pairs pass rail joints, longitudinal irregularities of rails and arrow crosses, as well as to improve smoothness, increase passenger comfort and ensure transportation safety, the chassis of the car is equipped with a spring suspension 6 (Fig. 1). Spring suspension elements reduce the acceleration of oscillatory motion and reduce the impact of dynamic forces on the carriage structure, ensuring smooth running during long-term operation [1-5].

Fig. 1Trolley of a freight car of type 18-100: 1 – wheelset, 2 – vertical brake gear lever, 3 – sliders, 4 – central pin assembly, 5 – brake lever transmission triangle, 6 – springs, 7 – axle box

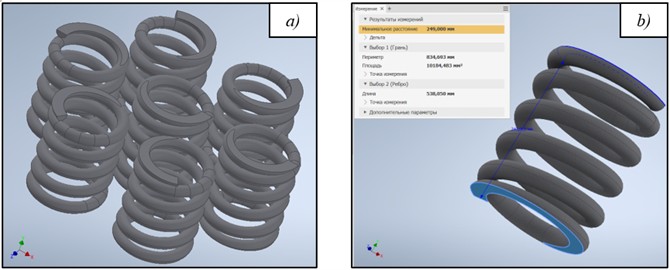

Currently, twisted cylindrical springs (Fig. 2) are widely used as elastic elements of the running gear of wagons [6, 7]. Due to their advantages such as high elasticity, ease of manufacture, ease of installation and disassembly, as well as long service life, they have almost completely replaced leaf springs [8-10].

The manufacture of twisted springs is a well-established energy-intensive technological process and includes the following operations: control of spring steel before commissioning, cutting rods, forming the profile part of the workpiece, heating for winding and winding, heat treatment (quenching followed by tempering), shot blasting, compression to remove residual deformation, end processing, testing, control check and coloring followed by drying [11, 12].

Fig. 2a) A set of external cylindrical springs of freight car bogies and b) the height of one spring in an unloaded state – 249 mm

To date, springs are strengthened by the following methods [13]:

– Cold plastic deformation followed by low-temperature tempering (aging).

– Quenching with tempering (hardening due to martensitic transformation).

– Quenching followed by aging (hardening by dispersion hardening).

Silicon steels 55Si2(A) and 60Si2(A) are widely used for the manufacture of springs and springs in automobiles and on rolling stock of railway transport. The work of these parts is associated with the use of only the elastic properties of steel, which depend on the design of the spring – the number of turns, their diameter and length [14]. Plastic deformation is unacceptable; therefore, a high elastic limit is required from the material, rather than high plasticity or toughness.

The main requirements for spring-loaded steel include high resistance to small plastic deformations and resistance to stress relaxation, which guarantees the accuracy of the springs and the stability of their performance characteristics. Spring steels are hardened by cold plastic deformation and quenching followed by tempering, and finished springs are subjected to stabilizing tempering [15, 16].

The highest performance properties are achieved at a hardness of HRC 40-45, which is ensured by quenching with full martensitic transformation and average tempering at a temperature of 400-500 °C, depending on the steel grade [17].

The operation of wagons is prohibited if cracks or fractures are found in the springs. The absence of at least one spring or closing of the coils is unacceptable. The springs must be installed without distortions, correspond to the type of car and the scheme of their placement, considering the distribution of the weight of the car along its length [18]. The height of the springs in the free state of the trolley 18-100 is 249 mm. In addition, it is not allowed to install springs with a height difference of more than 4 mm in one set.

The analysis of damage to springs and springs shows that all defects can be divided into two categories: defects associated with fatigue of the material, and subsidence caused by loss of elastic properties.

Fatigue failures begin with the formation of a small crack, which gradually increases. This crack originates on the surface in places where there is decarbonization of metal, minor defects, nicks and other factors that cause stress concentration [19].

The loss of elastic properties occurs gradually under the influence of operational loads, especially if the heat treatment of springs and springs was performed poorly.

Moreover, it was found that deviations from the norm of hardness of the steel springs of the spring set of cargo trucks in relation to the standard hardness parameters led to:

– Subsidence of the spring during operation.

– Reducing the height of the spring under the calculated static load.

– Reduction of the operating amplitude of the springs under load.

– Damage to the surface, followed by the rapid development of cracks and fractures.

– Reduction of the ductility characteristics of steel.

– Reduction of cyclic durability.

Taking into account the above circumstances, the purpose of this work was to improve the technology of heat treatment of structural spring steel 55Si2 to improve the quality and durability of springs for railway freight wagons.

2. Materials and methods

In this paper, experiments were carried out on heat treatment of the inner (diameter 22 mm) and outer springs (diameter 30 mm) of a freight wagon trolley to improve their mechanical properties. The springs were made of 55Si2 steel according to GOST 14959, the chemical composition of which is shown in Table 1, hardened by quenching in oil and medium tempering.

Table 1Chemical composition of steel 55Si2

Steel grade | Mass fraction of elements, % | ||||||||

C | Si | Mn | Cr | V | W | Ni | B | Cu, no more | |

55Si2 | 0,52-0,6 | 1,5-2,0 | 0,6-0,9 | < 0,3 | – | – | < 0,25 | – | 0,2 |

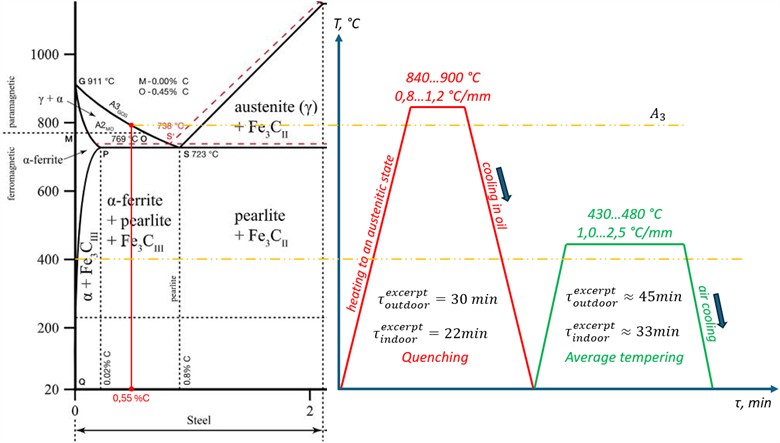

In works exposed influence temperature and length of heat treatment of mechanical properties of spring Apostille. Temperatures in cut temperaments vary from 840 to 900 aposematic C, and in cut breaks from 430 to 480 aposematic C (Fig. 3).

Fig. 3The mode of hardening heat treatment of steel 55C2

The duration of heat treatment in the quenching mode varied from 0,8 to 1,2 °C/mm, and in the tempering mode – from 1 to 2,5 °C/mm. More than 300 experiments with various processing modes were carried out, which made it possible to carry out comprehensive studies on the heat treatment of internal and external springs of freight car bogies in the conditions of pilot production.

3. Results and discussions

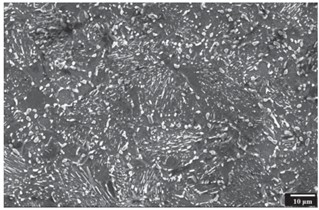

Fig. 4 shows the microstructure of 55Si2 steel, consisting of perlite with a small amount of pre-eutectoid ferrite, which is in a deformed state and randomly oriented. The white areas of the microstructure reflect various forms of undissolved cementite, which is also present in the material.

Fig. 4Microstructure of the steel under study: a) before hardening heat treatment; b) after heat treatment

a)

b)

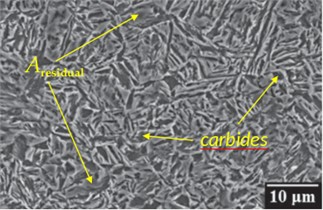

In the microstructure of steel after hardening heat treatment (Fig. 3(b)), a bainite structure is observed, which consists of dark etched bainite ferrite, soft ferrite in certain zones and residual austenite. At a temperature range of 460-480 °C, bainite acquires a wide feathery structure called upper bainite. The presence of soft ferrite is difficult to detect in samples with an upper bainite structure, since the bainite-ferrite structure formed at these temperatures also has a lamellar morphology similar to soft ferrite. With longer tempering and an increase in the conversion temperature (460-480°C), active nucleation of bainite ferritic needles occurs, which leads to an increase in bainite-ferritic plates [3]. As a result, the content of residual austenite in the material decreases.

After quenching, spring steel, having an increased carbon content in solid solution, demonstrates a high density of dislocations and twins, as well as a fine-grained structure. A decrease in grain size leads to an increase in resistance to small plastic deformations and a decrease in local stress concentrations at grain boundaries in the areas of junction of martensite crystals with the boundaries of the initial austenitic grain.

Stable crack development is observed along the boundaries of the former austenite grains, but the final fracture of the material occurs through the grain. It follows from this that steel with a fine-grained structure is less prone to brittle fracture, especially in a high-strength state and at temperatures below the transition temperature from a viscous state to a brittle one.

To minimize the risk of brittle fracture of steel, it is also necessary to reduce the level of internal stresses, since they negatively affect the elastic limit of the material. Moreover, the relaxation of these stresses during operation of the springs leads to instability of their characteristics. In this regard, it is advisable to use stepwise, and especially isothermal hardening of springs.

After the heat treatment, the spring steel should have a minimum content of residual austenite. The presence of residual austenite in the steel structure leads to a decrease in its relaxation resistance and tendency to slow destruction. This is due to the fact that under mechanical action, especially when cooled to low temperatures, austenite can be transformed into martensite. This transformation has a negative effect on the service life of the springs, causing premature wear even under static stress.

The main factor determining the increase in resistance to small plastic deformations during tempering is the decay of residual austenite. Despite its significant influence, the main role is played by structural processes in martensite – the formation of segregation and the separation of dispersed carbides coherently bound to the matrix.

4. Conclusions

During the research, quantitative dependences of the main technological parameters of heat treatment were obtained, which formed the basis of a new technological instruction for the production of trolley springs for freight wagons. This instruction reflects the effect of temperature and holding time in the furnace on the mechanical and operational properties of the springs.

The introduction of the proposed technology has significantly improved the quality of the finished product, improved its mechanical characteristics, and improved the macro- and microstructure of the metal compared to the previously used technology. In addition, this led to an increase in the yield of usable springs of freight car bogies.

References

-

A. Salokhiddin, T. Nodirjon, B. Erkin, A. Sadriddin, and K. Kholida, “Investigation of the carbon potential in a low-pressure environment for alloy steels after the carburizing process,” Universum: Technical Sciences, Vol. 9, No. 126, pp. 5–8, 2024.

-

V. M. Grigoriev, V. M. Mokienko, and P. V. Sokolov, “Analysis of the destruction of passenger car springs,” Transport in the Asia-Pacific region, pp. 94–97, 2015.

-

E. A. Pisisny, A. M. Markov, D. A. Gabets, and A. V. Gabets, “Investigation of the effect of chemical composition and structure on the impact strength of medium-carbon low-alloy steels designed for parts operating under conditions of impact and friction wear,” Polzunovsky Bulletin, No. 2, pp. 152–159, 2020.

-

O. Y. Burgonova, N. V. Mamonov, and N. V. Kolyagina, “The effect of alloying elements on the decarbonized layer of spring steel,” in Engineering and Technology Engineering, 2017, pp. 148–152.

-

X.-W. Wang et al., “Optimization of heat treatment for 38Si7 spring steel with excellent mechanical properties and controlled decarburization,” Materials, Vol. 15, No. 11, p. 3763, May 2022, https://doi.org/10.3390/ma15113763

-

Y. Yamada and T. Kuwabara, “Metallic material for springs,” in Materials for Springs, Berlin, Heidelberg: Springer Berlin Heidelberg, 2025, pp. 47–326, https://doi.org/10.1007/978-3-540-73812-1_2

-

P. Ostash, R. V. Chepil’, L. Markashova, V. Hrybovs’Ka, V. V. Kulyk, and Berdnikova, “Influence of the modes of heat treatment on the durability of springs made of 65G steel,” Materials Science, Vol. 53, No. 5, pp. 684–690, Jul. 2018, https://doi.org/10.1007/s11003-018-0124-0

-

R. Fragoudakis, S. Karditsas, G. Savaidis, and N. Michailidis, “The effect of heat and surface treatment on the fatigue behaviour of 56SiCr7 spring steel,” Procedia Engineering, Vol. 74, pp. 309–312, Jan. 2014, https://doi.org/10.1016/j.proeng.2014.06.268

-

J. Wang et al., “Effect of austempering temperatures on microstructure and mechanical properties of 52CrMoV4 spring steel,” Materials and Design, Vol. 253, p. 113898, May 2025, https://doi.org/10.1016/j.matdes.2025.113898

-

Y. Ma et al., “Effect of a new two-step austenitizing-Q&P process on the microstructure and mechanical properties of microalloyed 51CrMnV spring steel,” Journal of Alloys and Compounds, Vol. 1004, p. 175864, Nov. 2024, https://doi.org/10.1016/j.jallcom.2024.175864

-

A. Wiangkham, P. Aengchuan, K. Sudtachat, A. Ariyarit, S. Srisuk, and N. Thammachot, “Optimizing parameters of the pack carburizing process with natural energizers to improve the impact and hardness properties of low-carbon steel using NSGA-II-based artificial intelligence,” Journal of Materials Engineering and Performance, Vol. 33, No. 24, pp. 13954–13966, Nov. 2023, https://doi.org/10.1007/s11665-023-08953-8

-

M. Y. Semenov, A. E. Smirnov, L. P. Fomina, and S. N. U. Absattarov, “Determination of carbon potential and carbon mass transfer coefficient during vacuum carburizing of steels,” Metallography and Heat Treatment of Metals, No. 1, 2024.

-

V. M. Dubasov, E. P. Mogilnaya, and N. V. Ponomareva, “The influence of heat treatment modes on the structure and properties of the outer springs of rolling stock,” Resource-Saving Technologies of Production and Pressure Treatment of Materials in Mechanical Engineering, 2016.

-

E. S. Gordeeva, “Calculation of critical points for heat treatment of alloy steels,” Modern Problems of Machine Theory, Vol. 8, pp. 5–7, 2019.

-

C. Blankart, S. Wesselmecking, and U. Krupp, “Influence of quenching and partitioning parameters on phase transformations and mechanical properties of medium manganese steel for press-hardening application,” Metals, Vol. 11, No. 11, p. 1879, Nov. 2021, https://doi.org/10.3390/met11111879

-

A. Ourabi et al., “Effect of heat treatment on microstructure and mechanical properties of medium-carbon steel drawn wire,” SAE International Journal of Materials and Manufacturing, Vol. 16, No. 4, Sep. 2023, https://doi.org/10.4271/05-16-04-0026

-

R. Kumar, R. K. Dwivedi, V. P. Singh, B. Kuriachen, and N. A. Krishnan, “Influence of toughness and retained austenite on wear behaviour of carbide-free bainite in high silicon steel,” Transactions of the Indian Institute of Metals, Vol. 76, No. 9, pp. 2425–2434, Nov. 2022, https://doi.org/10.1007/s12666-022-02818-9

-

A. Abedini, H. Rastegari, and S. Emam, “Mechanical properties and work hardening behaviour of spring steel after the quenching-partitioning process,” Canadian Metallurgical Quarterly, Vol. 63, No. 4, pp. 1169–1182, Dec. 2023, https://doi.org/10.1080/00084433.2023.2291288

-

A. M. Markov, A. V. Gabets, D. A. Gabets, and D. V. Gavrikov, “Springs of the spring set of trolleys of freight wagons,” Actual Problems in Mechanical Engineering, No. 3, 2016.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.