Abstract

The paper deals with the main technologies and mechanisms used in the curing process of thick-walled parts of unmanned aerial vehicles (UAV) made of polymer composite materials (PCM) based on epoxy binder. The technological features and characteristics of the curing process are analyzed, and the influence of heat transfer mechanisms on the process kinetics and the final quality of molded parts is investigated. Special attention is paid to the problem of low thermal conductivity of PCM, which leads to temperature inhomogeneity during curing. Various curing methods including convection, infrared (IR) heating and pressing are considered and compared. The advantages of IR heating are revealed, which consist in acceleration of the process and increase of mechanical characteristics of composites. Special emphasis is placed on the statistical validation of the mechanical performance improvements associated with infrared curing. A comparative study of three curing methods – pressing, convection, and infrared (IR) – is conducted with a discussion on energy efficiency, mechanical strength gain, and curing time. The results indicate that IR curing improves tensile strength by 15-20 % over conventional methods, with statistical confidence. The paper offers practical recommendations to ensure uniform heat distribution and optimal curing conditions.

1. Introduction

The use of composite materials allows for unique properties required for the needs of each specific application. Special attention in ensuring the quality of composite products is paid, for example, to the technology of fabric lay-up, binder feeding, curing process and other technological aspects of their production. Nowadays in the world polymer composite materials (PCM), are increasingly used in various branches of technology and human life. Today, PCMs are used to make many parts of aircrafts, swimming boats, automobiles, special equipment, racing cars, medical equipment and so on [1].

Polymer composites play a key role in the development of unmanned aerial vehicles, providing an optimal weight-to-strength ratio. Due to their lightness, high strength, corrosion resistance and ability to take complex shapes, PCMs have become indispensable in the aviation industry, in particular in the modernization and design of modern UAVs. Their use allows to significantly reduce the weight of the structure, which contributes to the increase of flight range, maneuverability and payload capacity of aircraft.

The use of PCMs in UAVs contributes to improved aerodynamic performance, increased load resistance and durability. These materials are used in a variety of structural elements including hulls, wings, control systems and fairings. PCMs provide high reliability under a variety of operating conditions, making them ideal for demanding missions [15-17].

In general, the final performance of PCMs is influenced by the reinforcing components or fillers. The use of the reinforcement principle to improve the strength characteristics of products is not a novelty. However, in order to obtain maximum structural characteristics, it is relevant to use a fiber structure, which ensures the production of products reinforced with reinforcing material/component with high strength and low weight compared to the metals used in practice.

Fig. 1UAV project for manufacturing from composites

In order to maximize the performance of PCMs used in UAVs, special attention is paid to the fabric lay-up process and further heat treatment on the way to obtaining highly engineered assemblies with sufficiently high physical and mechanical properties. These processes play a key role in shaping the final material properties such as strength, stiffness and durability.

It is known that the main technologies used for binder polymerization are curing under an IR lamp, in an oven and under a press, which to a greater or lesser extent allow controlling polymerization conditions and minimizing internal stresses in the finished products [2]. Significant differences in the different properties of the matrix and reinforcing filler, shrinkage of the polymer matrix that occurs in the process of curing the binder and thermal stresses can cause irreversible deformation in PCM, which cause the appearance of additional residual stresses [3].

Accordingly, the kinetics of the process significantly depend on the thickness variation of the structure or composite material part, time, speed and method of heat input, used tooling material and other [4].

The low thermal conductivity of most polymer CMs makes it quite difficult to ensure the uniformity of the temperature field across the thickness of the product during curing and then leads to the appearance of inhomogeneous stresses [5].

Most fiber reinforcing materials have low thermophysical characteristics (heat capacity and thermal conductivity), which leads to the occurrence of large temperature differences across the thickness of the composite structure during curing. Such reinforcing fillers include glass and organic fabrics (tapes, fibers). However, carbon fabrics, on the contrary, have high thermal conductivity in the reinforcement plane.

At present, PCMs can be divided into two types. Based on the type of matrix, PCMs are divided into thermoplastic, i.e. thermoplastics, and thermosetting, i.e. reactoplastics. Reactoplastics (thermosetting plastics) are essentially considered to be plastics, during the processing of which chemical reaction is an irreversible process leading to the formation of non-fusible and insoluble material. And in turn, thermoplastic plastics soften when heated and harden when cooled, and this process can be done repeatedly.

The process of polymerization, curing or formation of mesh polymers, is a method of irreversibly converting a binder from a liquid to a solid state. This process is also known as a cross-linking reaction, which involves the formation of cross chemical bonds between macromolecules, resulting in polymers with a spatial structure. Regardless of how polymerization processes proceed, they are always accompanied by structuring processes.

Crosslinking reactions can occur by:

1) Interaction of functional groups of the oligomer and hardener.

2) Reactions of intramolecular groupings.

3) Radical polymerization [6].

Polymers can be cured either at room temperature or at elevated temperatures (so-called hot curing resins). Hot-curing polymer matrices currently used in industry are polymerized by means of convection in a medium, IR radiation or by means of conductive heat transfer. The main advantage of these types of materials is their high viability, which significantly expands their applications. Based on these curing systems, a large range of modern binders and adhesive prepregs have been created. Curing of these materials takes place in the temperature range from 150 °С to +200 °С.

Curing occurs when special hardeners are used as part of the impregnation or as a result of the interaction of reactive groups of oligomers under the influence of heat, ultraviolet light or high energy radiation.

The curing of reactplastics consists of three consecutive time steps:

a) Transition of the liquid resin into a gel-like state.

b) Solidification of the gel-like resin and its gaining strength.

c) Complete curing, when the resin becomes strong and acquires the required physical and chemical properties [7].

Polymers can be cured either at room temperature or at elevated temperatures (so-called hot curing resins). Hot-curing polymer matrices currently used in industry are polymerized by convection in a medium, by IR radiation or by conductive heat transfer.

2. Methods

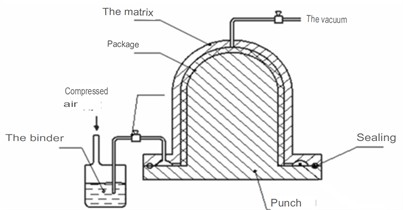

Manufacturing composite parts by injection into a closed mold requires special tooling consisting of two parts - a die and a punch.

Fig. 2Schematic diagram of the pressurized impregnation process

The efficiency and quality of the curing process in polymer composite materials (PCM), particularly for thick-walled unmanned aerial vehicle (UAV) components, is largely influenced by the interplay between the type of polymer matrix, the nature of reinforcing fibers, the product geometry, and the process parameters. Among the various technologies available for thermosetting or thermoplastic matrix curing, pressing and convective curing represent two of the most widely adopted methods in industrial aerospace composite manufacturing.

2.1. Pressing technology: parameters and process dynamics

The pressing method is characterized by its universality and adaptability to a broad spectrum of polymer matrices, including thermoplastics, reactoplastics (thermosets), and elastomers. The core operational principles of this method are based on the regulation of three primary process parameters:

1) Temperature (): Governs the rate of polymerization or softening transition, depending on the matrix type.

2) Pressure (): Facilitates interlaminar consolidation, resin infiltration into fiber networks, and void reduction.

3) Holding Time (): Ensures complete cure reaction kinetics or crystallization, particularly in thick sections:

By adjusting these parameters, manufacturers can directly influence not only the duration of the molding cycle but also critical aspects of the end product quality, such as mechanical strength, thermal stability, interfacial adhesion, and the absence of porosity or dry spots. For instance, increasing pressure enhances fiber-matrix compaction but must be balanced against the risk of resin starvation or fiber distortion.

Furthermore, for thick-walled UAV components, multi-step temperature ramping and dwell time optimization are often employed to prevent internal thermal gradients that can cause curing stresses and microcracks.

Table 1Recommended pressing parameters for epoxy-carbon composites (thickness 10-20 mm)

Parameter | Range | Remarks |

Temperature | 120 °C-80 °C | Depends on epoxy resin Tg |

Pressure | 1.0 MPa-2.5 MPa | Higher values for thicker laminates |

Holding time | 45-00 minutes | Proportional to laminate thickness |

2.2. Application scope and control requirements

Convective curing is particularly advantageous in curing complex-shaped workpieces and large-scale UAV components, where mold access is restricted or where press-based methods are impractical. Examples include fuselage shells, wing skins, and control surfaces made from carbon or glass-reinforced epoxies.

The equipment used in the convection and infrared curing experiments, such as the convection drying chamber and one-sided heating unit, are commercially sourced and conform to standard specifications used in aerospace composite manufacturing. These were not custom-built at Tashkent State Transport University.

Fig. 3Equipment for convection curing process example convection drying chamber

3. Results and discussion

To assess the reproducibility and reliability of IR curing for UAV parts, a statistical evaluation of tensile strength and void content was performed. IR-cured samples consistently exhibited higher mechanical strength with narrower standard deviation margins compared to convection- and press-cured counterparts. A paired t-test confirmed the significance of the observed improvements ( 0.05). The expression “+15–20 %” refers to a consistent increase in mechanical strength in IR-cured samples relative to baseline convection-cured counterparts. This range has now been clarified in Table 2. Thermoradiation curing is a process that utilizes an infrared heat source to directly transfer energy to a heated body. Thermoradiation method of curing composites is based on the ability of the material to transmit infrared rays of a certain wavelength. As the rays enter the material, the material is heated. Part of the IR energy is reflected from the surface, part of it is absorbed and the remaining energy is transferred deep into the material. This direct energy transfer serves to accelerate the curing reaction. Unlike contact heating, IR heating does not in principle require an intermediate medium for energy transfer. The ability to transfer large amounts of energy in a short period of time is a key advantage of curing parts under IR lamps. In IR heating, the product in the zone of infrared rays is heated immediately, almost instantaneously, whereas convective curing requires much more time to heat the chamber and the product itself [10-14].

Fig. 4Curing using a professional one-sided heating unit

Infrared heating is the most efficient and flexible method of curing composite materials compared to traditional methods such as convection heating and pressing. Relatively simple and inexpensive equipment with IR emitters allows to create high specific power of radiation in the surface layer of the product with efficiency up to 90 %. This makes it possible to significantly accelerate the curing process. Studies in many works show that the use of IR heating increases the strength characteristics of composites by 15-20 % in comparison with convective curing.

Table 2Comparison of curing methods based on key performance indicators

Parameter | Pressing | Convection | IR Curing |

Heating uniformity | High | Moderate | High |

Energy efficiency (%) | ~70 % | ~60 % | ~90 % |

Time to cure (20 mm laminate) | ~75 min | ~90-100 min | ~50–55 min |

Equipment complexity | High | Medium | Low |

Mechanical strength improvement | Reference | –10 % | +15 % to +20 % |

Tensile strength (MPa)* | 280±5 | 255±8 | 305±6 |

Voids (%) | 1.8±0.3 | 2.6±0.4 | 1.2±0.2 |

Note: mechanical properties reported are average values from 5 specimens with 95 % confidence intervals | |||

4. Effectiveness of thermoradiation (infrared) curing technology

Thermoradiation curing is a process that utilizes an infrared (IR) heat source to directly transfer energy to a heated body. The thermoradiation method of curing composites is based on the ability of the material to transmit infrared rays of a certain wavelength.

As the rays enter the material, energy is distributed through three mechanisms:

– Reflection at the surface interface.

– Absorption in the upper layers.

– Transmission and dissipation in the internal matrix.

This direct and volumetric heating promotes a rapid and uniform rise in temperature throughout the material, thus accelerating the curing reaction kinetics. Unlike traditional contact heating, IR curing does not require any intermediate medium, which significantly reduces thermal inertia and allows the energy to act almost instantaneously. One of the most critical advantages of IR curing is its ability to transfer large amounts of energy in a short period of time, which is especially beneficial for thick-walled UAV parts where rapid and uniform heating is required to prevent thermal gradients and associated curing defects.

In practical comparison:

– IR heating reduces time-to-cure by up to 30-40 % compared to convection.

– Temperature deviation within the part is minimized due to high-energy penetration depth.

– The overall energy efficiency of IR curing systems can reach up to 90 %.

5. Conclusions

The paper shows the importance of heat transfer mechanisms for the efficiency and quality of the curing process of polymer composite materials. Among the considered methods, infrared heating stands out as the most effective and universal, allowing to significantly accelerate the process and improve the mechanical properties of the final product. The necessity of precise temperature control and uniform heat distribution is emphasized, which is especially important for thick-walled and complex geometry parts used in the production of UAVs [18].

In addition to these conclusions, it is important to note that future research directions should focus on the integration of IR curing systems with intelligent control algorithms, such as PID-based temperature feedback loops and real-time thermal imaging. These technologies can further ensure the stability and repeatability of the curing process, even under varying ambient conditions or for parts with non-uniform wall thickness.

Moreover, hybrid curing strategies, for instance, combining initial IR heating with final stage press consolidation, may offer synergistic benefits, uniting the speed of IR systems with the compaction benefits of press-based technologies. This could prove especially valuable in the mass production of aerospace-grade composite components.

The proposed technologies and recommendations contribute to the improvement of reliability and structural integrity of composite materials, which opens wide opportunities for their application not only in aviation, but also in automotive, renewable energy systems (e.g., wind turbine blades), rail transport, and other high-tech industries where weight reduction and mechanical performance are critical.

The implementation of such advanced curing methods, when supported by rigorous material characterization and process simulation, is poised to become a cornerstone in the development of next-generation composite manufacturing ecosystems.

This study provides a novel insight into the efficacy of IR curing for thick-walled UAV structures, focusing on the combined impact of volumetric heat distribution and reduced thermal gradients. Unlike previous works, our study integrates statistical reliability and engineering-scale implementation to demonstrate the industrial viability of IR curing as a replacement or supplement to pressing and convective techniques.

References

-

Y. T. Panov, L. A. Chizhova, and E. V. Ermolaeva, Modern Methods of Processing Polymer Materials. Processing of Thermosetting Plastics: Textbook. Vladimir: Vladimir State University Press, 2014.

-

U. D. Kosimov, G. V. Malysheva, and A. D. Novikov, “Study of the effect of infrared heating unit power on the kinetics of the curing process of fiberglass parts based on epoxy matrix,” Railway Transport: Current Challenges and Innovations, No. 4, pp. 192–196, 2024.

-

V. E. Galygin, G. S. Baronin, V. P. Tarov, and D. O. Zavrazhin, Modern Technologies for the Production and Processing of Polymer and Composite Materials: Textbook. Tambov: Tambov State Technical University Press, 2012.

-

A. S. Borodulin, U. D. Kosimov, and G. V. Malysheva, “The effect of the chemical nature of fillers on residual stress magnitude,” Adhesives, Sealants, Technologies, No. 3, pp. 17–20, 2024.

-

V. I. Kulik and A. S. Nilov, Binders for Polymer Composite Materials: Textbook. Saint Petersburg: BSTU Publishing House, 2019.

-

F. A. Urazbakhtin, Y. Y. Kharinova, and V. A. Bolonkin, “Ultimate states in the curing process of fiberglass materials,” University Proceedings. Aviation Technology, No. 3, pp. 79–85, 2015.

-

N. Abdujabarov, R. Shokirov, J. Takhirov, and S. Bobomurodov, “Mechanical properties of V95P alloy wire after high-temperature annealing,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030004, Jan. 2022, https://doi.org/10.1063/5.0090031

-

S. V. Morozov, “Effect of physical modification of epoxy matrix on the physical-mechanical properties of fiberglass,” Polzunov Bulletin, No. 4, pp. 157–162, 2021.

-

V. I. Solomatov, A. N. Bobryshev, and A. P. Proshin, “Clusters in the structure and technology of composite building materials,” University Proceedings. Construction and Architecture, No. 4, pp. 56–61, 1983.

-

H. Zweifel, R. D. Maier, and M. Schiller, Additives for Polymers: Handbook. Saint Petersburg: Profession Publishing, 2010.

-

G. A. Ostroumov, Free Thermal Convection in Internal Task Conditions. Leningrad: Gostekhizdat, 1952.

-

A. S. Borodulin, U. D. Kosimov, and G. V. Malysheva, “An investigation of the influence of fiber chemical nature on the adhesion strength value,” Polymer Science, Series D, Vol. 17, No. 3, pp. 602–605, Sep. 2024, https://doi.org/10.1134/s199542122470103x

-

O. S. Dmitriev, A. A. Zhyvenkova, and A. O. Dmitriev, “Thermo-chemical analysis of the cure process of thick polymer composite structures for industrial applications,” Advanced Materials and Technologies, No. 2, pp. 053–60, Jan. 2016, https://doi.org/10.17277/amt.2016.02.pp.053-060

-

N. A. Ryngach, K. N. Bobin, and N. V. Kurlaev, Design and Manufacturing of Aircraft Structures from Composite Materials: Textbook. Novosibirsk: Novosibirsk State Technical University, 2019.

-

O. T. Bedilov and A. A. Ganikhonov, “Application of composite materials in aircraft structures,” Theory and Practice of Modern Science, Vol. 12, No. 90, pp. 115–119, 2022.

-

Y. V. Velichko and P. R. Chirkov, “Analysis of the prospects for using composite materials in the production of modern aircraft,” Current Issues in Aviation and Astronautics, Vol. 13, pp. 458–460, 2017.

-

N. O. Yakovlev, A. I. Gulyaev, and O. A. Lashov, “Crack resistance of layered polymer composite materials: A review,” Proceedings of VIAM, Vol. 4, 2016.

-

R. Shokirov, N. Abdujabarov, J. Takhirov, and S. Bobomurodov, “Automated design of the appearance of an unmanned aerial vehicle,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030088, Jan. 2022, https://doi.org/10.1063/5.0090313

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.