Abstract

The article analyzes how the temperature of the quenching medium during heat treatment influences the mechanical properties of spring steel grade 60Si2CrV. It presents the correlations between the quenching medium temperature and such parameters as hardness, tensile strength, and elongation. The study identifies the optimal cooling medium temperature range to be 20-30 °C, which ensures enhanced mechanical performance of the steel. The findings can be applied to improve the heat treatment processes of cylindrical springs used in freight wagons, thereby increasing their service life and operational reliability

1. Introduction

Most spring alloys are steels hardened by martensitic transformation, which provides high values of hardness and strength. These steels are used in various fields of mechanical engineering for the manufacture of highly critical elastic elements [1].

The hardening heat treatment of spring steels consists in quenching in oil followed by tempering. It has been found that the hardness of the springs obtained after such treatment increases dramatically. High hardness contributes to an increase in the elastic properties and tensile strength of spring steels, as a result of which residual deformations are sharply reduced, and due to this the springs work for a longer time without unacceptable losses of geometric and force parameters [2].

Cooling during quenching from the austenitic region should ensure the production of a martensitic structure. Cooling must be carried out at a rate higher than the critical quenching rate [3]. The high cooling rate should be in the temperature range of the minimum stability of austenite, and in the martensitic range it is desirable to reduce it in order to reduce the emerging internal stresses [4]. Mineral oils correspond to such cooling conditions.

Oil as a quenching medium has the following advantages: a low cooling rate in the martensitic temperature range, which reduces the occurrence of quenching defects, and a constant quenching ability in a wide range of medium temperatures. The disadvantages include increased flammability, insufficient stability and low cooling capacity in the range of pearlite transformation temperatures, as well as increased cost [5]. Mixing the oil effectively increases the speed and uniformity of cooling; during operation, the oil is oxidized, thickens and its cooling capacity decreases, which leads to frequent replacement of used oil with a new one [6].

The temperature of the quenching medium affects the critical quenching rate. The lower the oil temperature, the higher the cooling rate and vice versa [7]. The existing literature [8-11] recommends an oil temperature range from 40 to 80 °C for general purpose steels, but there are no lower and upper temperature limits for spring steels. Even with the presence of circulating equipment, the oil temperature in the quenching tank increases significantly at the time of lowering the batch of heated parts, which further reduces the cooling capacity. In addition, there are no systematic and literary data on the influence of the temperature of the cooling medium on the mechanical properties of steels, and therefore the purpose of this article was to establish the dependence of the temperature of the quenching medium on the mechanical properties of spring-spring steel 60Si2CrV, used for the manufacture of cylindrical springs of freight wagons of railway transport.

2. Materials and methods

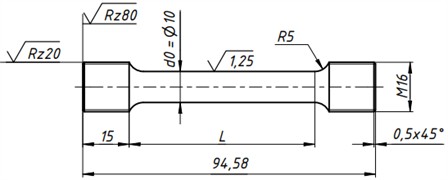

The object of the study was galtels in the amount of 14 pieces (Fig. 1), made according to GOST 1497-84 [12] from 60Si2CrV rods. The chemical composition of which is shown in Table 1.

Table 1Chemical composition of steel 60Si2CrV, (% by weight)

С | Si | Mn | Cr | V | Ni | S | P | Cu |

0,56-0,64 | 1,40-1,80 | 0,40-0,70 | 0,90-1,20 | 0,10-0,20 | ≤ 0,30 | ≤ 0,025 | ≤ 0,025 | ≤ 0,20 |

Fig. 1Samples made of 60Si2CrV steel: a) product drawing, b) 3D model of the sample; c) prepared galtels in the amount of 14 pieces

а)

b)

c)

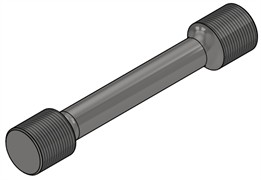

The heat treatment (Fig. 2) was carried out in an electric chamber furnace of periodic action in an oxidizing (air) atmosphere, the dimensions of the working space of which are 1200×1500×1000 mm. The test samples were heated for quenching together with springs to 880 °C, exposure time of 10 minutes at this temperature (from the schedule of hardenability of steel 60Si2CrV per 1 mm of the hardened zone, 1 min is required). Cooling was carried out in oil, the temperature of which varied from 5±2.5 to 40 ±2.5 °C. Such a significant tolerance of ±2.5 °C is due to the difficulty of maintaining the oil temperature constant during quenching. Next, the samples were tempered in the same way as in the quenching process, together with springs at a temperature of 510 °C. The duration of the vacation was 1 hour. The cooling was carried out in calm air. The temperatures of the critical points ( and ) for the steel grade under study are 760 and 820 °C, respectively [13].

Before measuring the hardness of the samples, the ends of the galtels were ground on a Buehler MetaservTM Vector LC 250 grinding and polishing machine (Fig. 3). Hardness was measured using a portable combined MET-UDA hardness tester (Fig. 4) on the “C” Rockwell scale according to the rebound principle. The measurement range is from 20 to 70 HRC, the margin of error is ± 2 HRC.

The rupture tests of the samples were carried out on a universal testing machine of the HMS-50 type No. 134 (Fig. 5). The HMS-50 machine is a stationary universal hydraulic testing unit with vertical load application to the test sample Measuring range is from 2000 to 50,000 kg. The error of the readings on the load scale is not more than ±1 % of the measured load.

Fig. 2The mode of heat treatment of steel 60Si2CrV

Fig. 3Buehler MetaservTM Vector LC 250 grinding and polishing machine

Fig. 4Portable combined MET-UDA hardness tester

Fig. 5Universal testing machine of the HMS-50

3. Results and discussions

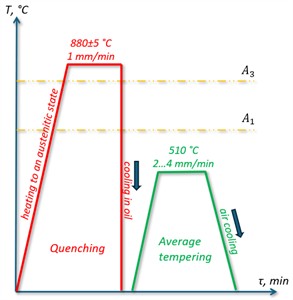

According to the results of the rupture test, macroscopic views of the fracture surfaces of the samples were obtained (Fig. 6), on which three zones are visible: 1 – fibrous zone, 2 – radial zone, 3 – cut zone.

The fibrous zone corresponds to the area of slow crack growth. It is located in the center of the fracture and surrounds the fracture site, which is located on the axis of tension. The fibrous zone consists of a region of randomly arranged thin circular furrows. The furrows are located perpendicular to the direction of crack propagation – from the focus to the periphery of the sample. Such features are inherent in stable subcritical cracks, the propagation of which requires relatively high energy costs.

The point at which the radial scars converge is the fracture site. The scars are quite thin, which is true for high-strength steels [13]. Thin radial scars indicate mainly the presence of a quasi-disc or intergranular fracture. The cut zone consists of a smooth ring-shaped area adjacent to the free surface of the sample. The surface of this zone is at an angle of ~45° to the axis of tension.

Fig. 6Fracture surfaces of samples after heat treatment

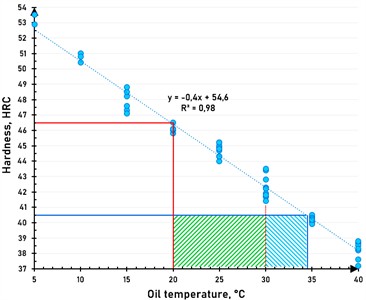

The dependence of the hardness of the studied samples on the temperature of the quenching medium is obtained (Fig. 7). The upper and lower limits of the oil temperature are shown. According to accepted standards, the spring hardness value should be in the range from 40.5 to 46.5 HRC. According to the data obtained, the lower oil temperature corresponds to 20 °C, and the upper ~ 35 °C. The green area shows the recommended temperature range, i.e. from 20 to 30 °C. This conclusion follows from the phenomenon of sagging springs, since when drilling, there is a decrease in the height of the spring more than the permissible one. The obtained dependence of hardness on oil temperature is linear with a coefficient of determination 0.9801. Thus, with an increase in the temperature of the quenching medium, the hardness of the finished product decreases.

Fig. 7The dependence of the hardness of steel 60Si2CrV on the oil temperature

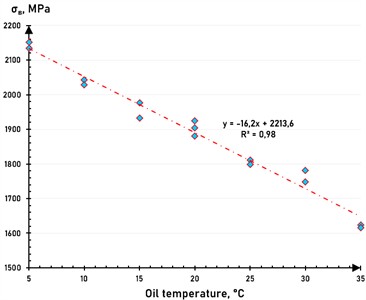

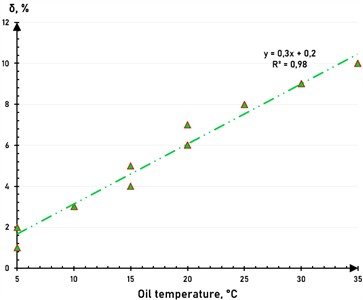

The dependence of the tensile strength and elongation is also linear with a correlation coefficient 0.9763 and 0.9767, respectively. (Fig. 8). According to GOST 14959-2016, the strength limit value for the brand under study should be at least 1670 MPa, and the elongation value should be at least 6 % [14]. In the interval above (see Fig. 7) the recommended oil temperature (20...30 °C) the value of the tensile strength lies in the range of ~1740... 1880 MPa, and the value of the elongation is 6 ... 9 %. Thus, the resulting dependencies (Fig. 8) do not contradict the requirements specified in the guest.

Fig. 8Dependence of mechanical properties: a) tensile strength, b) elongation, 60Si2CrV on oil temperature

a)

b)

4. Conclusions

1) The temperature of the quenching medium has a significant effect on the mechanical properties of 60Si2CrV steel. As the oil temperature increases, hardness and tensile strength decrease, and elongation increases.

2) The optimal temperature range of the quenching medium to ensure high mechanical properties is 20-30 °C. In this range, hardness values of 40.5-46.5 HRC, tensile strength of 1740-1880 MPa and elongation of 6-9 % are achieved.

3) The obtained linear dependence of mechanical properties on oil temperature makes it possible to predict the characteristics of steel when cooling conditions change, which can be used to optimize heat treatment processes.

4) The use of a cooling medium with the recommended temperature allows minimizing residual deformations of the springs and extending their service life without significant losses of geometric and power parameters.

References

-

A. Salokhiddin, T. Nodirjon, B. Erkin, A. Sadriddin, and K. Kholida, “Investigation of the carbon potential in a low-pressure environment for alloy steels after the carburizing process,” Universum: Technical Sciences, Vol. 5, No. 9(126), 2024.

-

Y. M. Tebenko and N. Y. Zemlyanushnova, “Analysis of methods for improving the quality of springs,” Defense Complex-Scientific and Technical Progress of Russia, No. 2, 2005.

-

N. K. Tursunov and S. N. Absattarov, “Improving the technology of heat treatment of structural spring steel in order to improve mechanical and operational properties,” in Problems of safety in transport: Materials of the XIII International Scientific and Practical Conference dedicated to the Year of Quality, pp. 153–155, 2024.

-

O. Toirov and N. Tursunov, “Efficiency of using heat-insulating mixtures to reduce defects of critical parts,” in E3S Web of Conferences, Vol. 401, p. 05018, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105018

-

M. A. Smirnov, V. M. Shchastyantsev, and L. G. Zhuravlev, Fundamentals of heat treatment of steel: A textbook. Yekaterinburg: Ural Branch of the Russian Academy of Sciences, 1999.

-

M. Y. Semenov, A. E. Smirnov, L. P. Fomina, and A. Salokhiddin Nuritdin-Ugli, “Determination of carbon potential and carbon mass transfer coefficient during vacuum carburizing of steel,” Metal Science and Heat Treatment, Vol. 66, No. 1-2, pp. 5–9, Jun. 2024, https://doi.org/10.1007/s11041-024-01010-8

-

U. Rakhimov and N. Tursunov, “Development of technology for high-strength cast iron for manufacturing D49 head of cylinder,” in E3S Web of Conferences, Vol. 401, p. 05013, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105013

-

A. M. Markov, A. V. Gabets, D. A. Gabets, and D. V. Gavrikov, “Springs of the spring set of trolleys of freight wagons,” Actual Problems in Mechanical Engineering, No. 3, pp. 194–198, Jan. 2016.

-

L. S. Malinov, I. E. Malysheva, and D. V. Malinova, “Influence of heat treatment with heating in the intercritical temperature range on the properties of steels 60Si2 and 60Si2CrV,” Metallurgical and Mining Industry, Vol. 4, No. 1, p. 27, Jan. 2012.

-

V. M. Dubasov, E. P. Mogilnaya, and N. V. Ponomareva, “The influence of heat treatment modes on the structure and properties of the outer springs of rolling stock,” Resource-Saving Technologies of Production and Pressure Treatment of Materials in Mechanical Engineering, No. 1, pp. 69–74, Jan. 2016.

-

U. Ziyamukhamedova et al., “Investigating friction and antiwear characteristics of organic and synthetic oils using h-BN nanoparticle additives: a tribological study,” Lubricants, Vol. 12, No. 1, p. 27, Jan. 2024, https://doi.org/10.3390/lubricants12010027

-

C. Shekhar, M. F. Wani, R. Sehgal, U. Ziyamukhamedova, and N. Tursunov, “A novel ceramic reinforced metal matrix composite (Cu-Ni/TiC-CaF2): fabrication, microstructure, mechanical and tribological characterization,” Metallurgical and Materials Transactions B, Vol. 56, No. 2, pp. 1289–1315, Jan. 2025, https://doi.org/10.1007/s11663-024-03418-2

-

E. S. Gordeeva, “Calculation of critical points for heat treatment of alloy steels,” Modern Problems of Machine Theory, No. 8, pp. 5–7, 2019.

-

C. Blankart, S. Wesselmecking, and U. Krupp, “Influence of quenching and partitioning parameters on phase transformations and mechanical properties of medium manganese steel for press-hardening application,” Metals, Vol. 11, No. 11, p. 1879, Nov. 2021, https://doi.org/10.3390/met11111879

-

C. Shekhar, M. F. Wani, R. Sehgal, S. S. Saleem, U. Ziyamukhamedova, and N. Tursunov, “Recent progress in particulate reinforced copper‐based composites: fabrication, microstructure, mechanical, and tribological properties-a review,” Advanced Engineering Materials, Vol. 27, No. 2, Dec. 2024, https://doi.org/10.1002/adem.202401748

-

H. Wang et al., “Effect of tempering temperature on the microstructure, deformation and fracture properties of an ultrahigh strength medium‐Mn steel processed by quenching and tempering,” Steel Research International, Vol. 94, No. 11, Mar. 2023, https://doi.org/10.1002/srin.202200902

-

L. Kuchkorov, S. Alimukhamedov, N. Tursunov, and O. Toirov, “Effect of different additives on the physical and mechanical properties of liquid-glass core mixtures,” in E3S Web of Conferences, Vol. 365, p. 05009, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505009

-

O. Toirov and N. Tursunov, “Development of production technology of rolling stock cast parts,” in E3S Web of Conferences, Vol. 264, p. 05013, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405013

-

E. S. Taranova and V. V. Komissarov, “Regularities of influence of operating factors on friction and wear characteistics at rolling,” Journal of Friction and Wear, Vol. 34, No. 2, pp. 142–146, May 2013, https://doi.org/10.3103/s106836661302013x

-

E. Del Molino et al., “Influence of Ni and process parameters in medium Mn steels heat treated by high partitioning temperature Q&P cycles,” Metallurgical and Materials Transactions A, Vol. 53, No. 11, pp. 3937–3955, 2022.

-

S. Azimov, O. Toirov, B. Xalmurzayev, S. Tursunov, and K. Khujakhmedova, “Using a cooling hole to improve the performance of transport brakes,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060016, Jan. 2024, https://doi.org/10.1063/5.0197365

-

J. Drumond, O. Girina, J. F. Da Silva Filho, N. Fonstein, and C. A. S. de Oliveira, “Effect of silicon content on the microstructure and mechanical properties of dual-phase steels,” Metallography, Microstructure, and Analysis, Vol. 1, No. 5, pp. 217–223, Oct. 2012, https://doi.org/10.1007/s13632-012-0034-8

Cited by

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.