Abstract

The article presents the results of the analysis of the causes of failure of large-size tyres operated in the conditions of Navoi MMC. On the basis of generalisation of the accumulated data the classification of the main factors leading to tyre failure is proposed. All causes are grouped into three key categories: wear, mechanical damage and thermal damage. Wear includes the processes of natural and accelerated tread abrasion, as well as various forms of uneven wear arising from deviations from the recommended operating conditions. Mechanical damage is considered as a result of short-term or long-term external impacts, including punctures, cuts, cord breaks and frame deformations. In 2024, the plant used more than 19 thousand car tires with a total value of about 1.4 trillion soums. These quarry dump trucks use tires manufactured by Bridgestone, Goodyear, Luan, Michelin, Techking, Advance, Aeolus, Maxam and Noble. For transport enterprises, the task of rational use of tire resources by improving the condition of quarry roads and reducing premature tire failure is relevant. The results obtained can be used to improve tyre maintenance and condition monitoring systems at mining enterprises.

1. Introduction

Large-size tyres (LST) are written off by tyre engineers together with the manufacturer’s representatives on the basis of technical inspection and diagnostics. The main reasons for writing off oversized tyres are tread wear, carcass damage, overheating, fatigue cracks and other defects [1, 7, 10]. Proper use, timely inspection and regular maintenance can extend the service life of tyres and reduce the cost of tyre replacement [2, 8].

The economic benefits associated with the use of quarry equipment in surface mining operations have led to a dramatic increase in the production of large tyres with rim diameters of 49 inches and larger. These tyres are subjected to mechanical and thermal damage during operation. The use of reinforcing fillers and processing additives in tyre compounds leads to the formation of microstructural inhomogeneities in the compounds and can be a source of crack initiation in the tyre. The main source of tyre cracks in mining tyres is hard rock (abrasive). Thus, it is sufficient to assume that each plane of material in the tyre consists of a crack precursor of known size that can nucleate under the load of the tyre duty cycle [3, 9, 11].

The study of tyre-surface contact for dump trucks operating on quarry process roads remains a challenging task, especially when considering the uncertainty and variability caused by operating conditions and terrain [4, 13, 15]. The static and dynamic tyre characteristics, applied load, inflation speed and pressure affect the tyre-terrain interaction, inducing forces and moments to meet traction and mobility requirements. These issues have been extensively analysed over the years and the contact of the tyre with a flat, rigid surface has also been studied in some detail. For example, controlling tyre inflation pressure alone helps to maintain preferred tyre-surface contact conditions in a wide range of on-road applications, and Tyre Tyre Pressure Measurement Systems (TMPS) are becoming standard on most quarry dump trucks [5, 12]. This can be particularly significant for critical vehicles that require high manoeuvrability to ensure survivability over a wide range of terrain types. However, the use of an active tyre pressure monitoring system, is also seen as a way of improving safety, handling and reducing fuel consumption on process roads for dump trucks. With these possibilities in mind, it is concluded that Crosstyre's Dynamic Pressure Equalisation Valves (DPEV) in tyres could be useful for automating pressure control. Pilot tests at the Navoi MCC plants show good results – maintaining stable pressure in the coupled tyre and reducing wear in the long term by up to 10 %.

The DPEV turns a pair of dual wheels on a dump truck into a single communicating volume, ensuring a constant pressure balance between both tyres. This solution facilitates automatic redistribution of internal pressure depending on external operating conditions – road surface, steering angle, load changes and other factors. As a result, a more even distribution of load between the wheels is achieved, local overstressing of rubber and carcass elements is reduced, which contributes to increased tyre life and uniform wear. The use of this technology significantly increases overall tyre life and reduces the likelihood of premature tyre failure.

A number of well-known scientists have developed various classifications of tires based on the signs of their premature failure. In these classifications, the causes of failure are divided into 5-8 groups [1, 2, 3]. At present, the large number of classification groups makes it difficult for tire engineers to register and analyze failure cases. Therefore, a pressing task is to generalize the types of failures of large-size tires, reduce the number of groups, and simplify the analysis.

2. Tyre failure analysis

Large tyre failures can be classified in various ways, based on the causes of failure and the nature of the damage. The main types of failures include the following categories [6, 14]:

1. Mechanical damage: cuts and punctures – occur when hitting sharp objects (metal, high-strength stones); tearing of the bracing layer (cord) – occurs due to overloading or heavy impact; deformations sidewall – result from impacts and reduced tyre pressures, as well as large longitudinal gradients of roads redistributing loads along the axles.

2. Tread wear: uneven wear – caused by improper load distribution; accelerated (aggressive) wear – occurs when operating conditions are not right (high speeds, overloads or longitudinal gradients); shoulder wear – occurs as a result of inadequate tyre pressure.

3. Delamination and delamination: tread delamination is a common problem due to loss of adhesion between layers; breaker delamination is caused by poor quality curing or overheating from high ambient temperatures; curing defects – insufficient adhesion between layers.

4. Thermal damage: overheating of the tyre – leads to cords breaking and ply deformation; tread melting – the result of prolonged use at high speeds or a large longitudinal gradient of the transport distance.

5. Manufacturing defects: insufficient ply adhesion – leads to early tread separation; uneven ply thickness – reduces tyre life; cortex defects – related to violation of production technology.

6. Fatigue damage: microcracks and cracks in the sidewall – develop gradually due to constant loads; fatigue failure of the frame - long-term cyclic loads leading to fatigue of the material.

The runnability of large-size tyres is individual for each enterprise and depends on mining and geological conditions and operating parameters. The main quality indicators of cGC tyres are: runnability, service life (km); cut and wear resistance; endurance/reliability; productivity (TKPH); traction properties; operator comfort and fuel efficiency [6].

Wear is the gradual or accelerated deterioration of the tread and tyre structure during use.

Types of wear and tear:

1) Normal or natural (even) wear. Tread rubber is frayed, protective and/or working breaker cables are exposed. Operation is permitted up to the second visible layer of breaker.

Suspension elements of the machine are in good condition, technological roads correspond to norms (Fig. 1).

Fig. 1Normal (uniform) wear: a) Techking tyres; b) Michelin tyres

a)

b)

2) Uneven, accelerated wear. Such wear is associated with faulty machinery (Fig. 2(a)), untimely rotation, or a combination of these factors. Sawtooth block wear is associated with high speed in turns (Fig. 2(c)). Can be detected early with regular inspections. Degree of rubber wear on one side of the tread does not allow safe tyre operation (Fig. 2(b)). Caused by additional friction when the wheel rolls. Friction causes an additional temperature rise inside the tyre.

Fig. 2Uneven wear: a) tyre wear due to machinery failure; b) one-sided wear; c) sawtooth wear

а)

b)

с)

3) Accelerated, aggressive wear. The tread rubber has numerous explosions (Fig. 3) caused not by abrasion but by aggressive action of the road surface. Caused by coarse fraction of road surface underlay, hardness of the underlay material, tread rubber compound not complying with standards, slipping on hard aggressive surface. Remedied by normalising road conditions, correct choice of rubber compound.

Fig. 3a) Accelerated and b) aggressive tyre wear

а)

b)

Classification of mechanical and thermal damage to tyres:

1) Damage to the tread part (visible defects, tears, punctures, deformation).

2) Damage to the sidewall (cuts, swelling, cracks, delaminations).

3) Damage to the on-board area (cord destruction, rubber delamination, deformation).

4) Damage caused by repairs (poor quality vulcanisation, repeated defects).

5) Other damage (thermal fracture, fatigue cracks, overheating).

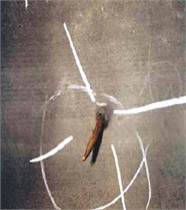

Mechanical damage: Through puncture of the tread. A puncture is accompanied by damage to the tread rubber, protective and working bracing cables, carcass and germ layer. It refers to instant damage caused by hitting sharp rocks or a foreign object (Fig. 4). The possibility of repair is determined depending on the size and nature of the damage.

Fig. 4a), b) Damage by foreign object and c) sharp rock

а)

b)

с)

Mechanical damage: non-penetrative. Damage reaches the working bracing layers, accompanied by puncture of the tread rubber and damage to the protective and working bracing cables. The carcass and germ layer remain intact (Fig. 5). The cause is a collision with a sharp foreign object. The damaged tyre is not repairable.

Consequences: the tyre continues to be used for a long time, but corrosion develops inside, the structure is weakened, which can lead to a sudden loss of pressure without breaking the carcass cables.

Fig. 5Tyre carcass and germ layer remaining intact: a) Techking and b) Michelin

а)

b)

Mechanical damage: puncture. The damage is accompanied by puncture of the tread rubber, destruction of the protective and working bracing cables. The integrity of the carcass and sealing layer is compromised, rendering the tyre unrepairable. The main cause is a collision with a sharp foreign object at high speed. Consequences: instant loss of pressure and large-scale tyre rupture.

Mechanical damage: cut with subsequent delamination. The damage is accompanied by puncture of the tread rubber and destruction of the protective and working bracing cables. The carcass and the sealing layer remain intact. The main cause is a collision with a sharp foreign object and subsequent use of the tyre. Consequences: Corrosion development along the bracing cables, especially accelerated at high tyre operating temperatures. Ultimately, the tyre is unrepairable due to the damage.

Mechanical damage – through cut in the sidewall. The defect is characterised by a puncture of the tyre sidewall with possible damage to the radial carcass and butyl sealant layer. It occurs most often in loading and unloading areas as a result of contact with sharp rock fragments or falling stones from the body of a dump truck. The extent of the damage and the size of the tyre can be restored.

Mechanical damage - swelling with tearing of the sidewall. The defect is characterised by a radial tear in the sidewall rubber or a tear at the edge of the bulge accompanied by localised delamination. In most cases, the radial carcass remains intact and the sidewall area of the tyre is not deformed. The outer surface of the sidewall may show signs of mechanical impact in the form of scuffs and abrasions caused by contact with foreign objects (Fig. 6).

The main cause of damage is the impact load. A slight breach of the integrity of the sealing layer leads to gradual penetration of air into the internal cavity between the carcass and sidewall rubber, which in time causes tearing. Such a defect is irreversible and cannot be repaired.

Fig. 6Tearing of sidewall rubber by contact with foreign objects

а)

b)

Mechanical damage – bulging of the sidewall (with or without tearing) due to damage to the bead during mounting. The defect is characterised by deformation of the sidewall and visible damage to the rubber on the seating surface of the bead, which can only be detected after disassembly of the tyre. The main cause of damage is non-compliance with the technological process of mounting, which includes insufficient use of lubricants, uneven distribution of load on the rim elements during mounting, as well as assembly work without the use of a specialised bench (Fig. 7).

This type of damage is irreversible and cannot be repaired due to the significant disruption of the rubber structure and the risk of further damage during operation.

Fig. 7a) Disturbance of rubber structure and b) its damage on the boarding surface

а)

b)

Mechanical damage - sidewall swelling (with or without rupture) due to damage to the bead during tyre movement. The defect is characterised by deformation of the sidewall and visible damage to the rubber to metal cord on the bead seating surface, which only becomes visible when the tyre is disassembled. The main cause of the damage is contact of the bead area with metal elements during transport or mounting, such as forks or forklift buckets, crane hooks and other rigid structures.

This damage results in the integrity of the on-board area being compromised, rendering the tyre unrepairable and precluding its further use due to the high risk of depressurisation and fracture during operation.

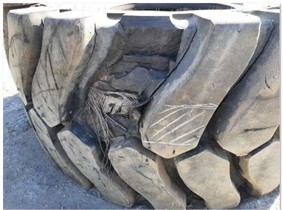

Thermal damage: detachment of the tread rubber due to overheating. Thermal damage manifests itself as a detachment of the tread rubber, but usually no exposed breaker cables are observed. However, in case of significant overheating, localised destruction of the rubber between the bracing layers is possible. As a result of changes in the physical properties of the material, the rubber becomes dark, sticky, with signs of carbonisation, accompanied by the appearance of soot and the characteristic smell of burning rubber.

The main cause of this damage is the exceeding of the permissible operating temperature inside the solid tyre structure, including the inter-breaker space. Factors contributing to overheating:

– Operation of the tyre at parameters exceeding the factory set limits (TKPH) [4].

– The tyre’s internal pressure does not match the load conditions.

– Increased rolling friction due to road conditions.

– Exceeding the permissible average operating speed.

This type of damage is not repairable. The lower the wear of the tyre, the higher the probability of overheating due to increased rolling resistance. Most often thermal degradation is observed on the front wheels of dump trucks. The degradation process is irreversible. This problem can only be eliminated by improving the operating conditions, in particular by improving the road surface. As a result of overheating, delamination cavities are formed inside the rubber mass, which increase in size with each revolution of the wheel (Fig. 8(a)). The deformation can propagate both along the rolling axis and transversely, which accelerates tyre failure (Fig. 8(b)).

Fig. 8Thermal damage to the tyre: a) detachment of the rubber in the tread area due to overheating and b) development of thermal damage in the transverse direction

а)

b)

Repair-related damage. The damage is characterised by a sudden loss of pressure in the tyre caused by damage in the area of the previous repair (Fig. 9). The main cause of these damages is non-compliance with technological requirements during repair work.

Factors leading to this type of injury include:

– Use of low-quality repair materials, expired expiry date, storage conditions that do not meet the standards.

– Incorrect selection of the size and type of repair patch depending on the characteristics of the lesion.

– Incorrect positioning of the patch in relation to the damaged area.

– Violations of the technology of preparation of the repaired surface (shape and depth of the funnel, insufficient cleaning and treatment of the surface before applying adhesive and vulcanising compositions).

– Failure to observe the temperature regime in the room during the renovation.

Failure in the repair area results in a complete loss of serviceability of the tyre, as the weakened area becomes a critical zone prone to repeated defects and depressurisation.

Other damage caused by operational abnormalities, including overloading and tyre underinflation. Typical tyre damage caused by operational abnormalities include excessive deformation of the sidewall in contact with the rim flange and cracking of the sealing layer (germ layer). These defects typically occur when tyres are used for extended periods of time under overloaded conditions or under reduced internal pressure, resulting in abnormal stress distribution in the carcass and loss of structural integrity.

Fig. 9Tyre damage due to non-compliance with technological requirements during repair work: a) tread, b) inner part of sidewall

а)

b)

Modern tyre pressure and temperature monitoring systems, such as MEMS4, allow early detection of deviating parameters and thus prevent the development of critical damage. The integration of such systems into the operational process significantly increases the reliability and safety of tyre products.

Other damage to large tyres not included in the main categories, but which significantly affects their service life and operational safety. These damages usually occur suddenly and can lead to catastrophic tyre failure. Such damage includes:

Fatigue damage to the carcass and tyre liner. Fatigue processes develop in the tyre structure during prolonged use, especially under conditions of cyclic overloads and deformations. The most susceptible to fatigue damage are textile or metal carcass and tyre liner elements. The result is the formation of microcracks with subsequent accumulation of damage leading to partial or complete rupture of cords, weakening of the bond between the plies, local loss of strength and, ultimately, tyre failure (Fig. 10(a)).

Fig. 10a) Fatigue damage of frame elements and b) damage caused by accidents

а)

b)

Damage caused by exposure to electric current (including lightning or contact with power lines). In cases where the busbar is exposed to high voltages, e.g. lightning or contact with a broken high voltage cable, localised thermal and electrical damage occurs. As a result of electric current exposure, thermal decomposition of rubber components with subsequent carbonisation, swelling or local destruction of the material in the area of the conductive channel may occur. At the same time, charring of frame elements may be observed, resulting in loss of their strength and load-bearing characteristics.

Deformation and damage caused by contact with aggressive chemicals, particularly petroleum products. Direct or prolonged contact with oils, fuels, solvents and other petrochemical substances causes swelling of rubber components, destruction of polymer matrix, reduction of strength and elasticity. As a result of such processes, sidewall deformation, tread peeling, and reduction of inner layer tightness are possible. Exposure to chemically aggressive substances is particularly dangerous for the hermetic layer, as it leads to air leakage and pressure drop to critical values.

Damage caused by road traffic accidents (crashes). Accidents can be accompanied by a sharp dynamic impact on the tyre (impacts, lateral shifts, jammed objects), which leads to complex damage: from sidewall and bead tears to destruction of the entire load-bearing structure (Fig. 10(b)). Such damage is often accompanied by irregular carcass deformation, tread separation, depressurisation and, in some cases, instant tyre collapse. After such incidents, further use of the tyre is strictly prohibited, regardless of the apparent extent of the damage.

3. Conclusions

As a result of the analysis of the causes of premature failure of large-size tires, in order to facilitate and simplify the electronic analysis by tire engineers, the classification was divided into the following three main groups:

1) Tyre wear. This group includes the processes of degradation of operational properties occurring both as a result of natural ageing and under the influence of unfavourable operating conditions. The following forms of wear are distinguished:

– Natural wear - gradual reduction of tread thickness within the normal service life.

– Accelerated (aggressive) wear – is expressed in intensive abrasion of the tyre’s working surface under the influence of increased loads, substandard pressure or aggressive environment.

– Uneven wear – manifested as unilateral, sawtooth wear, as well as localised wear in the central or lateral areas of the treadway caused by improper wheel mounting angles, imbalance, or systematic deviation from the recommended operating conditions.

2) Mechanical damage. These are the result of short-term or long-term exposure to external forces exceeding the values permissible for the tyre structure. The main types of mechanical defects include:

– Through damage (punctures, punctures) to the tread or sidewall.

– Non-penetrating damage (cuts of various depths) with possible seal failure.

– Tears in bracker layers, cord, hermolayer.

– Deep cuts to the metal cord, accompanied by secondary delamination of structural elements.

– Sidewall bulges caused by internal tears in the frame.

– Damage to the on-board area caused by careless transport, assembly/disassembly or contact with sharp objects.

3) Thermal damage. Occurs under the action of abnormal thermal effects capable of breaking the integrity of the rubber-cord structure. The main forms of thermal damage:

– Detachment of the tread rubber caused by overheating due to prolonged driving with reduced pressure or excessive load.

– Localised damage due to electric shock (e.g. in case of violation of the rules for working on quarry equipment).

– Internal or external tyre fires are usually the result of prolonged exposure to high temperatures, mechanical damage or chemical reactions.

A thorough understanding of the causal mechanisms underlying tyre damage is a key prerequisite for the development and implementation of effective measures aimed at their prevention and elimination. Analysis of the factors leading to premature tyre failure allows not only to identify characteristic defects and conditions of their occurrence, but also to formulate reasonable technical and organisational solutions aimed at improving reliability, extending service life and ensuring safe tyre operation.

References

-

E. S. Skornyakov, Large-Size Tires of Cars and Tractors. Dnepropetrovsk: Porogi, 2000, p. 263.

-

D. Manas, M. Manas, M. Stanek, and V. Pata, “Wear of tire treads,” Journal of the Franklin Institute, Vol. 237, No. 3, p. 214, Mar. 1944, https://doi.org/10.1016/s0016-0032(44)90333-9

-

W. Nyaaba, “Thermomechanical fatigue life investigation of an ultra-large mining dump truck tire,” Missouri University of Science and Technology, 2017.

-

U. Yusupov and X. Shavkatov, “Development of a standard mileage for large-sized tires under moderately severe quarry conditions,” in BIO Web of Conferences, Vol. 141, p. 04034, Nov. 2024, https://doi.org/10.1051/bioconf/202414104034

-

R. G. Longoria, R. Brushaber, and A. Simms, “An in-wheel sensor for monitoring tire-terrain interaction: Development and laboratory testing,” Journal of Terramechanics, Vol. 82, pp. 43–52, Apr. 2019, https://doi.org/10.1016/j.jterra.2018.12.004

-

V. A. Topalidi and M. E. Israilov, “Determination of the actual TKPH index of large-size tires in quarry conditions,” Automobile Industry, No. 8, pp. 12–14, 2024.

-

A. Mukhitdinov, U. Yusupov, S. Tukhtamishov, and Q. Urinbayev, “Results of the study of the influence of an average longitudinal slope of routes on the life of tires in the quarry,” Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 040041, Jan. 2024, https://doi.org/10.1063/5.0197301

-

U. Yusupov, O. Kasimov, and A. Anvarjonov, “Research of the resource of tires of rotary buses in career conditions,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030073, Jan. 2022, https://doi.org/10.1063/5.0089590

-

U. Yusupov and A. Mukhitdinov, “Evaluation of the influence of the longitudinal slope of carriage roads on the tire life,” in E3S Web of Conferences, Vol. 401, p. 03025, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103025

-

V. Topalidi, U. Yusupov, and S. Allaberganov, “Improving the efficiency of transport logistics support,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030072, Jan. 2022, https://doi.org/10.1063/5.0089587

-

S. Tursunov and R. Khikmatov, “Increasing environmental safety, increasing service life of ice units and assembly and saving fuel consumption through application of multifunctional fuel additives,” in E3S Web of Conferences, Vol. 365, p. 01012, Jan. 2023, https://doi.org/10.1051/e3sconf/202336501012

-

A. Mukhitdinov, K. Ziyaev, J. Omarov, and S. Ismoilova, “Methodology of constructing driving cycles by the synthesis,” in E3S Web of Conferences, Vol. 264, p. 01033, Jun. 2021, https://doi.org/10.1051/e3sconf/202126401033

-

K. Nurmetov, A. Riskulov, and A. Ikromov, “Physicochemical aspects of polymer composites technology with activated modifiers,” in 2nd International Scientific Forum on Computer and Energy Sciences (WFCES-II 2021), Vol. 2656, p. 020011, Jan. 2022, https://doi.org/10.1063/5.0106358

-

R. Sanjarbek, J. Mavlonov, and A. Mukhitdinov, “Analysis of the powertrain component size of electrified vehicles commercially available on the market,” Communications – Scientific letters of the University of Zilina, Vol. 24, No. 1, pp. B74–B86, Jan. 2022, https://doi.org/10.26552/com.c.2022.1.b74-b86

-

U. Abdurazzokov, B. Sattivaldiev, R. Khikmatov, and S. Ziyaeva, “Method for assessing the energy efficiency of a vehicle taking into account the load under operating conditions,” in E3S Web of Conferences, Vol. 264, p. 05033, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405033

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.