Abstract

Based on the field pulling test of BFRP anchor, this study studied the stress-strain distribution of BFRP anchor solids of different lengths, analyzed the spatial and temporal distribution of stress-strain, shear stress distribution, axial force characteristics and shear slip displacement characteristics of the interface between BFRP anchor and slurry, and discussed the working mechanism of BFRP anchor solids of different lengths. The effect of bonding length of BFRP bolt on bonding properties between bolt and grout was quantified. The test results show that: The strain of BFRP bolt increases with the increase of load, and decreases with the increase of buried depth; The axial force increases with the increase of cyclic load and decreases with the increase of anchoring depth; The interfacial shear stress decreases exponentially along the anchoring depth, which can be divided into fast decay and slow decay stages; The bonding strength increases with the increase of bonding length, and the strength increases by 2 % to 27 % for every 0.5 m increase in length. This understanding of shear stress distribution helps in accurately assessing the load - transfer mechanism and the potential failure modes of the anchoring system, which is crucial for improving the design and safety of geotechnical anchoring projects.

1. Introduction

In the modern era, the remarkable progress in transportation construction engineering has been a significant driving force for economic development and regional connectivity. However, a considerable number of infrastructure projects are invariably confronted with the harsh reality of being located in complex and highly unstable geological mountainous terrains. These regions are prone to a variety of geological hazards, with landslides and collapses being among the most prevalent and menacing. Such disasters not only imperil the structural integrity and safety of the engineering works during construction and operation but also have far-reaching and detrimental impacts on the surrounding ecological balance. The destruction of natural landscapes, alteration of watercourses, and disruption of wildlife habitats are just some of the ecological consequences that can ensue.

The research domain of Basalt Fiber Reinforced Polymer (BFRP) bolts has garnered substantial attention and witnessed a prolific body of work both within and outside the national boundaries. Scholars from diverse academic and research institutions have been actively engaged in investigating the mechanical characteristics of BFRP bolts in the context of their practical engineering applications. BFRP, as an innovative non-metallic composite material, has emerged as a promising alternative in the field of engineering. It exhibits a host of remarkable engineering attributes, most notably its exceptional resistance to corrosion and durability. These properties make it particularly well-suited for geotechnical anchorage engineering, where the long-term stability and integrity of the anchoring system are of paramount importance. In geotechnical engineering, the stabilization of rock masses is a critical aspect, and anchoring technology serves as a fundamental and effective means to achieve this goal. It is widely utilized in a range of engineering structures such as tunnels, which require secure support to withstand the immense pressure exerted by the surrounding rock; foundation pits, where proper anchoring is essential to prevent soil collapse and ensure the safety of the excavation process; and slope protection works, which are designed to safeguard against the potential slippage and failure of slopes.

Historically, steel reinforcement has been the traditional and dominant material choice for anchor bolts. It has served the engineering community well for an extended period, owing to its well-established mechanical properties and relative ease of manufacturing and installation. However, as engineering projects have increasingly longer service lifetimes and are often exposed to complex and aggressive geotechnical environments, the limitations of steel reinforcement have become more pronounced. Groundwater, which may contain various corrosive substances, and chemical pollutants present in the soil can gradually erode and corrode steel bolts over time. The consequences of such corrosion are not only the degradation of the mechanical strength of the bolts but also the potential for sudden and catastrophic failure, which can have disastrous consequences for the overall stability of the engineering structure [1].

In light of this formidable challenge and the need for more reliable and sustainable anchoring solutions, a significant cohort of scholars and researchers has redirected their focus towards the exploration and development of novel anchoring materials. This has led to the advent and rapid evolution of Fiber Reinforced Polymer (FRP) anchors. FRP materials, with their unique combination of lightweight, high strength, and excellent corrosion resistance, offer a viable alternative to traditional steel anchors. Among the different types of FRP anchors, BFRP anchors have shown particular promise due to the inherent properties of basalt fibers [3].

To further contribute to the understanding and optimization of BFRP anchor rods in geotechnical anchoring applications, this study undertakes a comprehensive field pull test of fully bonded BFRP anchor rods under cyclic loading conditions. By doing so, it aims to address the existing research lacunae and provide a more robust, scientific, and all-encompassing theoretical framework. This will, in turn, enable engineers and designers to make more informed decisions when formulating engineering designs and construction plans, ultimately leading to enhanced overall stability and safety of the projects.

2. Dynamic model test design for stress and strain distribution analysis of fully bonded BFRP anchoring system

The main object of the model is BFRP bolt and its anchoring system. Firstly, the model size of BFRP bolt is obtained by conversion according to the test similarity ratio design. Then, follow the following steps to develop the model: (1) Preparation of BFRP anchor material; (2) anchor rod positioning and installation; (3) Construction of anchoring system; (4) Model pouring and curing; (5) Model demoulding and preparation.

3. Experimental results

3.1. Analysis of strain time history curve of BFRP anchor

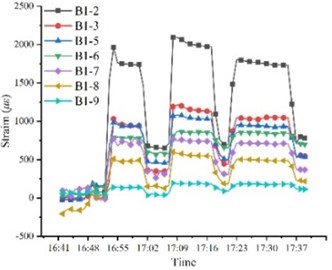

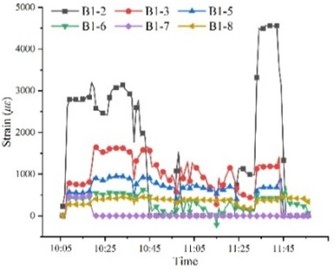

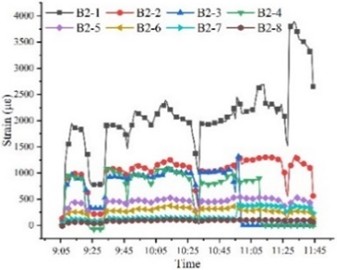

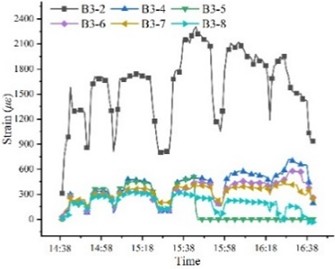

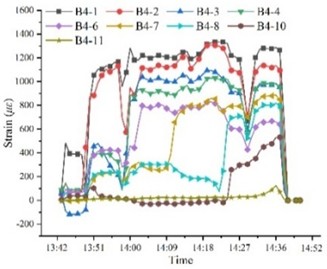

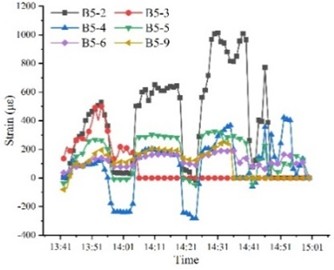

To investigate the strain response of BFRP bolts under cyclic load, strain history curves of different-length bolts are drawn. Fig. 2(a) shows B1 bolt’s strain change after rainstorm interruption. Fig. 2(b) shows next day's strain distribution, reflecting anchorage force weakening and strain increase, especially at the bolt top. From Fig. 2(c-f), bolt strain of each length is positively correlated with cyclic load, increasing with load and decreasing with anchoring depth. Generally, the strain history curve of BFRP anchor bolt has obvious stage changes: rapid strain increase on loading, fluctuation or stability on holding load, and rapid decay on unloading.

Fig. 1Physical diagram of prefabricated bolt process

Fig. 2Strain time history curve of BFRP bolt under cyclic loading (Note: the total length of bolt B1, B2, B3, B4 and B5 is 2.8 m, 3.3 m, 3.8 m, 4.3 m and 4.8 m, respectively)

a) B1 bolt strain time history curve - same-day test

b) B1 bolt strain time history curve - next day test

c) Strain time history curve of B2 bolt

d) strain time history curve of B3 bolt

e) B4 bolt strain history curve

f) B5 bolt strain history curve

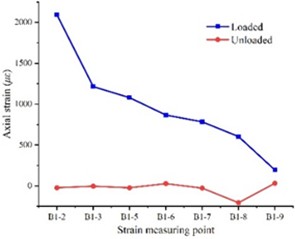

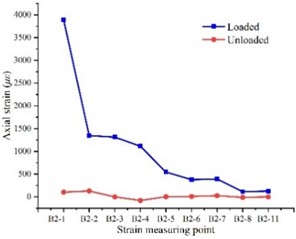

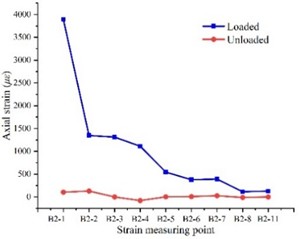

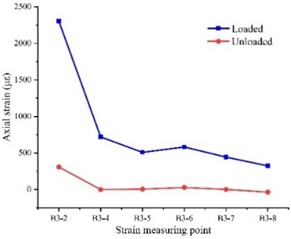

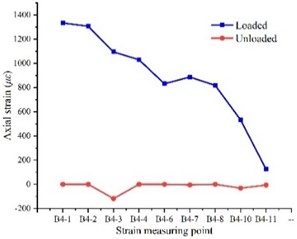

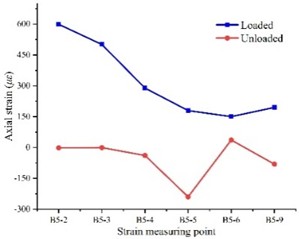

3.2. Analysis of distribution characteristics of axial strain of BFRP anchor along anchoring length

This study analyzed axial strain response of BFRP anchors (different lengths, depths). The strain of the B1 bolt shows changes between the “day” test and the “next day” test. After a rainstorm interruption, the strain distribution on the next day reflects a weakening of the anchorage force and an increase in strain, especially at the bolt top. This indicates that external factors over time, rainfall, can influence the performance of the BFRP anchor. Drew distribution curve by extracting data. Results: strain unevenly distributed, concentrated near hole mouth, decreases with depth. Similar to other bolts. After unloading, strain near zero, some points negative, showing rebound etc. [4-6].

Fig. 3Axial strain distribution curves of BFRP bolts of different lengths under cyclic loading (Note: the total lengths of B1, B2, B3, B4 and B5 bolts are 2.8 m, 3.3 m, 3.8 m, 4.3 m and 4.8 m, respectively)

a) B1 axial strain distribution curve of bolt – same-day test

b) B1 axial strain distribution curve of bolt – next day test

c) Axial strain distribution curve of B2 anchor bolt

d) axial strain distribution curve of B3 anchor bolt

e) B4 bolt axial strain distribution curve

f) B5 bolt axial strain distribution curve

3.3. Analysis of shear stress distribution characteristics at the first interface of BFRP anchoring system

BFRP anchor bolt anchoring system is composed of BFRP anchor bolt, bonding material and rock and soil mass to form two interface synergies. A large number of studies and engineering practices show that the failure of the anchor bolt anchoring system mainly occurs at the anchoring interface, and the interface shear stress direction gradually softens with the increase of time, resulting in the failure and failure of the anchoring structure. The shear stress distribution characteristics of the anchoring system play a crucial and decisive role in its bearing performance, and the anchoring length of the bolt has a significant impact on the bearing performance of the anchoring system. Quantitative analysis of interfacial shear stress variation along bonding length is of great practical significance to clearly understand the bearing capacity of the anchoring system. Therefore, in order to understand the distribution characteristics of shear stress at the first interface of BFRP anchoring systems of different lengths, quantitative analysis and analysis of BFRP anchors of different lengths are carried out in this section.

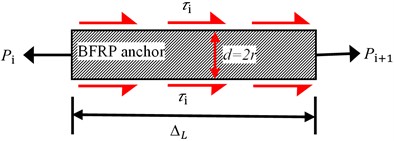

The unit body between two measuring points adjacent to the BFRP anchor rod is taken as the research object. It is assumed that the shear stress between two measuring points adjacent to the interface of BFRP anchor rod is evenly distributed under the action of pulling load, as shown in Fig. 4. In order to correspond to the number of strain measuring points in the on-site pulling test of anchor rod, is defined as the loading direction of pulling load.

Fig. 4Diagram of stress balance between two strain measuring points of BFRP anchor under drawing load

According to the stress characteristics of BFRP anchor under drawing load, the expression of interface mechanical balance of BFRP anchor between two adjacent measuring points is established:

where is the axial force at the measuring point, is the axial force at the measuring point, is the average shear stress between and measuring point, is the diameter of BFRP anchor rod, is the length between the measuring point and measuring point.

Eq. (1) is further simplified to obtain the shear stress expression of BFRP bolt interface under cyclic drawing load:

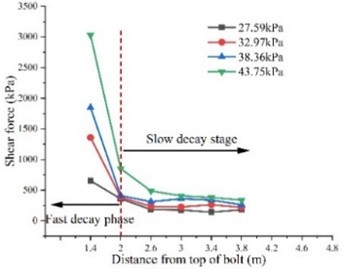

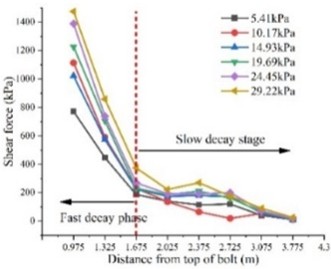

As some BFRP anchor strain measuring points were damaged, only B1 and B2 anchors with good points were analyzed for interfacial shear stress (Fig. 5(a, b)). Shear stress of these bolts decays exponentially along anchoring depth, mainly near orifice, in two stages: rapid near orifice then slow to near zero. B1 (4.8 m) and B2 (4.3 m) bolts’ rapid attenuation points are at 2 m and 1.675 m. Longer bolts’ shear stress extends deeper. Also, BFRP anchor rod's shear stress rises with cyclic load, showing external load’s impact [7-9].

4. Conclusions

This paper examines the stress and strain distribution in BFRP bolts with varying anchor lengths through field tests. Key findings include:

1) BFRP bolt strain correlates positively with cyclic load and negatively with anchorage depth, decreasing as depth increases.

2) Interfacial shear stress distribution follows an exponential curve, with rapid attenuation near the hole section and a slower decline towards the hole bottom.

Fig. 5Distribution curve of interface shear stress of BFRP bolt along anchoring depth

a) B1 bolt 4.8 m

b) B2 bolt 3.8 m

References

-

Z. Peng et al., “Mechanical behavior of BFRP cable rock bolts: experimental and analytical study,” Journal of Composites for Construction, Vol. 28, No. 5, p. 04024, Oct. 2024, https://doi.org/10.1061/jccof2.cceng-4657

-

S. M. Harle, “Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review,” Structures, Vol. 60, p. 105881, Feb. 2024, https://doi.org/10.1016/j.istruc.2024.105881

-

L. Zhu, J.-W. Kang, W. Zhao, Q. Xie, and X.-J. Gao, “Experimental study on determining design parameters of non-prestressed BFRP anchor for supporting soil slope,” Journal of Highway and Transportation Research and Development (English Edition), Vol. 11, No. 4, pp. 32–42, Dec. 2017, https://doi.org/10.1061/jhtrcq.0000593

-

K. Cui, D. H. Wang, W. W. Chen, X. F. Ren, J. Liu, and G. Yang, “Comparative study on anchoring performance of three kinds of bolts based on modified glutinous rice mortar,” Rock and Soil Mechanics, Vol. 39, No. 2, pp. 498–506, 2018.

-

R. L. He, P. Zhang, N. Li, and B. C. Liu, “Working mechanism of full-length bonded bolt under drawing conditions,” Journal of Central South University (Natural Science Edition), No. 2, pp. 401–407, 2006.

-

J. F. Zhou, “Test on mechanical properties of anchor rod during drawing,” Science Technology and Engineering, Vol. 21, No. 25, pp. 10873–10879, 2021.

-

X. P. Cui, F. Su, and W. Sun, “Analysis of solid load transfer mechanism and characteristics of anchor bolt based on hole wall shape,” Coal Science and Technology, Vol. 49, No. 8, pp. 96–102, 2021.

-

H. F. Xu, W. Wang, M. Jiang, and S. Tong, “Theoretical analysis of tensile deformation and stiffness of grouted rock bolt,” Chinese Journal of Geotechnical Engineering, Vol. 33, No. 10, pp. 1511–1516, 2011.

-

G. W. Li, L. Gao, Z. H. Huang, C. Q. Liu, and D. Zhang, “Failure mechanism pull-out model test of full-length bonded glass fiber reinforced polymer anchor rod,” Chinese Journal of Rock Mechanics and Engineering, No. 8, pp. 1653–1663, 2007.

About this article

This research is supported by the Science and Technology Research and Development Program of China Railway Corporation Limited (2023-Major Special-04); Chongqing Transportation Technology Project (CQJT2022ZC20)

We would like to express our gratitude to Teacher Honggang Wu for his work on visualization, investigation, resource allocation, project management, supervision, and funding acquisition in this article. Also, we are thankful to Lin Tang and Haiyu Yang for their contributions in terms of conceptualization, research methodology, validation, formal analysis, re-validation, conceptualization again, as well as review and editing in the article.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.