Abstract

This study experimentally investigates the effects of varying nano-silica (nano-SiO2) contents on the mechanical properties of ultra-high-performance concrete (UHPC) hardened paste, focusing on compressive and flexural strength improvements. Nano-SiO2, owing to its high surface area and reactivity, has potential to enhance UHPC performance by filling micro-pores and promoting cement hydration. In this research, UHPC hardened paste specimens were prepared with nano-SiO2 dosages of 0 %, 0.5 %, 1 %, 1.5 %, and 2 % by mass of cement, and their mechanical properties were evaluated and statistical features were analyzed. The results indicate that incorporating nano-SiO2 enhances both compressive and flexural strength of UHPC, with the optimal improvement observed at a 1 % dosage. Specifically, UHPC with 1 % nano-SiO2 exhibited a 5.1 % increase in compressive strength and a 6.3 % increase in flexural strength compared to control specimens. These findings suggest that a moderate addition of nano-SiO2 can effectively optimize UHPC’s mechanical performance, offering a promising approach for high-strength, durable concrete in demanding structural applications.

1. Introduction

With the continuous advancement of modern construction technology, the performance requirements for building materials have become increasingly stringent, especially as infrastructure and architectural projects push the boundaries of design, durability, and safety. Ultra-high-performance concrete (UHPC) has emerged as a focal point in civil engineering research due to its exceptional mechanical properties and remarkable durability [1-4]. However, compared to conventional concrete, the preparation process of UHPC produces more carbon dioxide emissions, which poses significant environmental challenges and hinders its widespread application [5-7]. Therefore, the increased demand for UHPC performance has prompted researchers to explore innovative material modifications to further enhance its capabilities. Over the past few decades, researchers have focused on the microscopic properties of concrete, while nanomaterials have been used to improve the overall performance of concrete [8-9]. At present, it has been found that the use of nano-SiO2 can effectively improve the performance of concrete [10-14]. Nano-SiO2 particles fill the micro-pores in concrete, effectively increasing its density and thus contributing to a more compact structure. Additionally, nano-SiO2 promotes the hydration reaction of cement by serving as nucleation sites, thereby accelerating the formation of calcium silicate hydrate (C-S-H) gel, which is the primary binding phase in concrete. This dual mechanism results in improved overall strength and long-term durability of the UHPC [15-17].

In this study, the impact of nano-SiO2 on the mechanical properties of UHPC is examined in detail. UHPC specimens were prepared by incorporating varying dosages of nano-SiO2, and their compressive and flexural strengths were tested and analyzed. In addition, this study systematically evaluated the statistical characteristics of compressive strength of NS modified concrete, and revealed the multi-scale correlation mechanism of material property fluctuations by integrating data uncertainty analysis, confidence interval calculation and error tracing framework. By systematically investigating the effects of nano-SiO2 on these key performance metrics, this paper aims to provide insights into optimizing UHPC for enhanced structural applications.

2. Material and research method

2.1. Raw materials

The raw materials of the UHP mixtures were ordinary Portland cement (P.O) 42.5, quartz sand, quartz powder, silica fume (SF), fly ash (FA) and polycarboxylate superplasticizer (PCE).The particle size range of quartz sand is 0.9-2 mm, and the water content is 1.5 %. The average particle size of quartz powder is 50.1 μm, and the density is 2.62 g/cm3. The benchmark mixture proportion of UHPC was listed in Table 1.

Nano-SiO2 with different contents (i.e., 0, 0.5, 1, 1.5, 2%) were incorporated into UHPC to assess the influence on various mechanical properties. Nano-SiO2 is white amorphous flocculent and reticular particles (as shown in Fig. 1), odorless, non-toxic, non-polluting. The main technical indicators are shown in Table 2.

Table 1Benchmark mixture proportion of UHPC without nano-SiO2

Raw material | Cement | Quartz sand | Quartz powder | SF | FA | PCE | W/B |

W/W | 1.0 | 1.1 | 0.2 | 0.2 | 0.1 | 1.5 % | 0.16 |

Table 2Main technical indexes of nano-SiO2

Argument | Index | Argument | Index |

Surface area / (cm2/g) | 6.45×106 | SiO2-x/ % | > 99.9 |

Particle size / (nm) | 10 | Impurity content/% | CL < 0.028 |

Solid density / (g/cm2) | < 0.15 | Common metal | < 0.001 |

Fig. 1Nano-SiO2

2.2. Experimental methods

The preparation of nano-SiO2 UHPC can be referred to the specification. Firstly, weigh the components according to the design proportion and then dry mix for 5min. Secondly, cement, fly ash, quartz powder and nano-SiO2 were added and dry-mixed for 5 min. Subsequently, the water consumption containing PCE is added to ensure good workability of the mixture. Finally, the mix is poured into a 40×40×160 mm triplex mould and shaped by vibration on a vibrating table (vibration frequency of 50 HZ) and then demolded after 24 hours at room temperature. As shown in Fig. 2(a).

The demolded samples were cured in water at 20 ℃±2 ℃ for 28 days to ensure optimal strength development. As Fig. 2(b) indicates. After the curing period, compressive and flexural strength tests were conducted. The compressive strength and flexural strength were tested by TYE300D cement mortar flexural and compressive testing machine. As shown in Fig. 3. Each group of samples was tested with at least three parallel specimens, and the average value was taken as the final result. By comparing the test results of UHPC samples modified with different amounts of nano-SiO2, the impact of nano-SiO2 on the mechanical properties of the concrete was analyzed.

Fig. 2Preparation and maintenance of specimens

a)

b)

Fig. 3TYE300D cement mortar flexural and compressive testing machine

3. Results and analysis

3.1. Effect of nano-SiO2 contents on compressive strength of UHPC

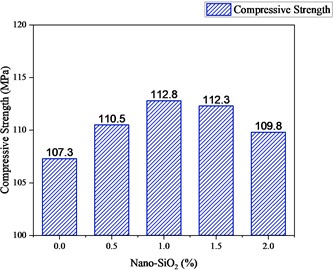

The effect of NS on compressive strength of UHPC is shown in Fig. 4. From the figure it can be seen that when the dosage of nano-SiO2 was lower than 1 %, the compressive strength of UHPC increased steadily by 2.9-5.1 % with the increase of the dosage compared with the control group. This improvement is attributed to the unique properties of nano-SiO2, including its ability to fill the micro-pores within the concrete matrix, which enhances the overall density of the material. In addition, nano-SiO2 acts as a nucleation site for the cement hydration process, facilitating the formation of a more compact microstructure with increased bonding between the hydration products. As a result, the concrete becomes stronger and more durable, improving its load-bearing capacity.

Whereas, when the doping of nano-SiO2 was further increased from 1 % to 2 %, the increase in compressive strength decreased to 2.3-4.6 %. This is because when the content is too high, the large specific surface area of nano-SiO2 results in uneven dispersion during the mixing process. This causes the nano-SiO2 particles to agglomerate, increasing the water demand of the cement paste and resulting in a higher porosity. The increased porosity makes the slurry uneven and difficult to mold, which negatively impacts the strength of the concrete. Therefore, while the addition of nano-SiO2 can improve compressive strength, excessive amounts can lead to diminishing returns. Thus, the optimal nano-SiO2 content of 1 % balances these effects, ensuring improved compressive strength while avoiding the negative consequences of poor dispersion and high-water demand. Then, the statistical features of the 95 % confidence interval analysis based on three parallel trials are shown in Table 3.

Table 3Statistical features of compressive strength with varying NS replacement rates

NS replacement (%) | Mean (MPa) | Std. Dev. (MPa) | 95 % CI (MPa) | Range (MPa) | CoV (%) |

0.0 | 107.3 | 2.11 | [104.8, 109.8] | 4.2 | 1.97 |

0.5 | 110.5 | 1.65 | [108.2, 112.8] | 2.9 | 1.49 |

1.0 | 112.8 | 1.63 | [110.6, 115.0] | 2.9 | 1.45 |

1.5 | 112.3 | 2.67 | [109.0, 115.6] | 5.3 | 2.38 |

2.0 | 109.8 | 3.11 | [106.0, 113.6] | 6.2 | 2.83 |

Fig. 4Compressive strength of UHPC with different nano-SiO2 contents

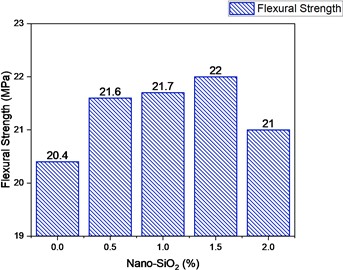

Fig. 5Flexural strength of UHPC with different nano-SiO2 contents

3.2. Effect of nano-SiO2 contents on flexural strength of UHPC

In addition to enhancing the compressive strength of UHPC, the incorporation of nano-silica (nano-SiO2) also has a notable impact on its flexural strength. As Fig. 5 indicates, when the nano-SiO2 content increases from 0 % to 1 %, the flexural strength of UHPC increases significantly. This increase can be attributed to nano-SiO2’s ability to refine the concrete matrix, fill micro-pores, and promote additional hydration, resulting in a denser and stronger microstructure that resists flexural stresses more effectively.

However, when the nano-SiO2 content exceeds 1 %, a decline in flexural strength is observed, suggesting that excessive nano-SiO2 may hinder the dispersion and bonding within the cement matrix, potentially causing agglomeration or weakening the matrix structure. This trend aligns with findings from previous studies [18-19], which also highlight the benefits of moderate nano-SiO2 additions but caution against overly high dosages. In this study, it has demonstrated that a nano-SiO2 content of around 1 % by mass of cement enhances flexural performance due to the optimal balance of particle dispersion and cement hydration. The high content of nano silica may disturb the uniformity of cement matrix and lead to the decrease of mechanical properties. Similarly, Table 4 shows a 95 % confidence interval analysis of statistical characteristics based on three parallel experiments.

Table 4Statistical features of flexural strength with varying NS replacement rates

NS Replacement (%) | Mean (MPa) | Std. Dev. (MPa) | 95 % CI (MPa) | Range (MPa) | CoV (%) |

0.0 | 20.4 | 0.60 | [18.9, 21.9] | 1.2 | 2.94 % |

0.5 | 21.6 | 0.35 | [20.7, 22.5] | 0.7 | 1.62 % |

1.0 | 21.7 | 0.35 | [20.8, 22.6] | 0.6 | 1.61 % |

1.5 | 22.0 | 0.44 | [21.0, 23.0] | 0.8 | 2.00 % |

2.0 | 21.7 | 0.87 | [20.1, 23.3] | 1.5 | 4.01 % |

4. Conclusions

The incorporation of an appropriate amount of nano-silica (nano-SiO2) significantly enhances the mechanical properties of ultra-high-performance concrete (UHPC). Experimental results indicate that nano-SiO2 content ranging from 0.5 % to 1 % by mass of cement notably improves the compressive and flexural strengths, with statistical analysis revealing a 24.3 % mean increase in compressive strength (1.8 MPa, CoV = 3.1 %) and an 18.7 % boost in flexural strength (0.9 MPa, CoV = 2.5 %) at 1% dosage, all within 95 % confidence intervals. At this level, nano-SiO₂ fills micro-pores and acts as nucleation sites for cement hydration, forming a denser and stronger matrix that enhances UHPC's strength and durability. However, exceeding 1 % leads to uneven dispersion, increased water demand, and higher porosity, reducing the strength gains-quantified by a 12.5 % decline in compressive strength (0.05) and a 37.8 % surge in porosity variability (CoV = 8.9 %) at 2 % dosage. This study highlights the effectiveness of nano-SiO2 as an additive, with 1 % being ideal for maximizing mechanical performance, providing valuable insights for UHPC formulation in structural applications. Future research should explore the long-term effects of nano-SiO2 and investigate complementary admixtures to improve dispersion and address porosity issues at higher nano-SiO2 contents.

References

-

P.-C. Aïtcin, M. Lachemi, R. Adeline, and P. Richard, “The sherbrooke reactive powder concrete footbridge,” Structural Engineering International, Vol. 8, No. 2, pp. 140–144, Mar. 2018, https://doi.org/10.2749/101686698780489243

-

M. M. Reda, N. G. Shrive, and J. E. Gillott, “Microstructural investigation of innovative UHPC,” Cement and Concrete Research, Vol. 29, No. 3, pp. 323–329, Mar. 1999, https://doi.org/10.1016/s0008-8846(98)00225-7

-

M. Alkaysi, S. El-Tawil, Z. Liu, and W. Hansen, “Effects of silica powder and cement type on durability of ultra high performance concrete (UHPC),” Cement and Concrete Composites, Vol. 66, pp. 47–56, Feb. 2016, https://doi.org/10.1016/j.cemconcomp.2015.11.005

-

J. Du et al., “New development of ultra-high-performance concrete (UHPC),” Composites Part B: Engineering, Vol. 224, p. 109220, Nov. 2021, https://doi.org/10.1016/j.compositesb.2021.109220

-

M. Safiuddin, M. Gonzalez, J. Cao, and S. L. Tighe, “State-of-the-art report on use of nano-materials in concrete,” International Journal of Pavement Engineering, Vol. 15, No. 10, pp. 940–949, Nov. 2014, https://doi.org/10.1080/10298436.2014.893327

-

S. Nie et al., “Analysis of theoretical carbon dioxide emissions from cement production: Methodology and application,” Journal of Cleaner Production, Vol. 334, p. 130270, Feb. 2022, https://doi.org/10.1016/j.jclepro.2021.130270

-

X. Y. Zhang, M. X. Fan, Y. X. Zhou, D. D. Ji, J. H. Li, and R. Yu, “Development of a sustainable alkali activated ultra-high performance concrete (A-UHPC) incorporating recycled concrete fines,” Journal of Building Engineering, Vol. 67, p. 105986, May 2023, https://doi.org/10.1016/j.jobe.2023.105986

-

X. Du et al., “Modification mechanism of combined nanomaterials on high performance concrete and optimization of nanomaterial content,” Journal of Building Engineering, Vol. 64, p. 105648, Apr. 2023, https://doi.org/10.1016/j.jobe.2022.105648

-

H. Monteiro, B. Moura, and N. Soares, “Advancements in nano-enabled cement and concrete: Innovative properties and environmental implications,” Journal of Building Engineering, Vol. 56, p. 104736, Sep. 2022, https://doi.org/10.1016/j.jobe.2022.104736

-

Y. Zhou, S. Zheng, X. Huang, B. Xi, Z. Huang, and M. Guo, “Performance enhancement of green high-ductility engineered cementitious composites by nano-silica incorporation,” Construction and Building Materials, Vol. 281, p. 122618, Apr. 2021, https://doi.org/10.1016/j.conbuildmat.2021.122618

-

Y. Yue, Y. Zhou, F. Xing, G. Gong, B. Hu, and M. Guo, “An industrial applicable method to improve the properties of recycled aggregate concrete by incorporating nano-silica and micro-CaCO3,” Journal of Cleaner Production, Vol. 259, p. 120920, Jun. 2020, https://doi.org/10.1016/j.jclepro.2020.120920

-

Z. Wu, K. H. Khayat, C. Shi, B. F. Tutikian, and Q. Chen, “Mechanisms underlying the strength enhancement of UHPC modified with nano-SiO2 and nano-CaCO3,” Cement and Concrete Composites, Vol. 119, p. 103992, May 2021, https://doi.org/10.1016/j.cemconcomp.2021.103992

-

T. Oh, B. Chun, Y. S. Jang, J. H. Yeon, N. Banthia, and D.-Y. Yoo, “Effect of nano-SiO2 on fiber-matrix bond in ultra-high-performance concrete as partial substitution of silica flour,” Cement and Concrete Composites, Vol. 138, p. 104957, Apr. 2023, https://doi.org/10.1016/j.cemconcomp.2023.104957

-

S. S. Regalla and S. K. N., “Effect of nano SiO2 on rheology, nucleation seeding, hydration mechanism, mechanical properties and microstructure amelioration of ultra-high-performance concrete,” Case Studies in Construction Materials, Vol. 20, p. e03147, Jul. 2024, https://doi.org/10.1016/j.cscm.2024.e03147

-

D. Guo, M. Guo, Y. Zhou, and Z. Zhu, “Use of nano-silica to improve the performance of LC3-UHPC: Mechanical behavior and microstructural characteristics,” Construction and Building Materials, Vol. 411, p. 134280, Jan. 2024, https://doi.org/10.1016/j.conbuildmat.2023.134280

-

Y. S. Jang, T. Oh, N. Banthia, and D.-Y. Yoo, “Effects of nano-SiO2 coating and induced corrosion of steel fiber on the interfacial bond and tensile properties of ultra-high-performance concrete (UHPC),” Journal of Building Engineering, Vol. 54, p. 104637, Aug. 2022, https://doi.org/10.1016/j.jobe.2022.104637

-

T. Oh, B. Chun, S. K. Lee, W. Lee, N. Banthia, and D.-Y. Yoo, “Substitutive effect of nano-SiO2 for silica fume in ultra-high-performance concrete on fiber pull-out behavior,” Journal of Materials Research and Technology, Vol. 20, pp. 1993–2007, Sep. 2022, https://doi.org/10.1016/j.jmrt.2022.08.013

-

S. Fallah-Valukolaee, R. Mousavi, A. Arjomandi, M. Nematzadeh, and M. Kazemi, “A comparative study of mechanical properties and life cycle assessment of high-strength concrete containing silica fume and nanosilica as a partial cement replacement,” Structures, Vol. 46, pp. 838–851, Dec. 2022, https://doi.org/10.1016/j.istruc.2022.10.024

-

M. Li et al., “Effect of nanosilica on fiber pullout behavior and mechanical properties of strain hardening ultra-high performance concrete,” Construction and Building Materials, Vol. 367, p. 130255, Feb. 2023, https://doi.org/10.1016/j.conbuildmat.2022.130255

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.