Abstract

In practical applications, Super absorbent polymers (SAP) can have certain adverse effects on concrete. Incorporation of SAP could lead to changes in the pore structure, thereby affecting strength. At the same time, SAP could also present cost challenges. To address these issues, a specific modifier can be incorporated into the SAP internally curing concrete. In this paper, the mechanical properties of nano-SiO2 and fly ash composite modified SAP internal curing concrete were investigated. The mechanical properties of the composite modified SAP were reflected through compressive strength and tensile strength tests as well as porosity mutual verification. The results indicate that nano-SiO2 and fly ash increase the strength of the modified SAP internal curing concrete and reduce the porosity. When the maximum content of nano-SiO2 reaches 3 %, the modification effect is more favourable. Under the combined effect of nano-SiO2 and fly ash, both the strength and porosity of SAP internal curing concrete are improved.

1. Introduction

In order to meet the requirements of higher strength and durability, cement concrete is gradually evolving towards lower water-binder ratio, denser pore structure and lower permeability [1]. Therefore, it is difficult to achieve the desired conservation effect by conventional conservation methods. The internal structure of concrete is susceptible to high internal stresses due to shrinkage, which increases the likelihood of the formation and propagation of cracks [2]. In response to the challenges associated with traditional concrete during the curing process, the advancement of construction technology has led to the emergence of internal curing technology [3]. The exceptional water dilution capabilities of super absorbent polymer (SAP) internal curing materials have prompted extensive research endeavours [4].

However, some issues have been identified in the practical implementation of SAP-internal curing concrete that are challenging to disregard. The incorporation of SAP may result in an increase in the porosity of the concrete, which in turn affects its compactness and the final mechanical properties of the concrete [5-6]. The most effective solution to these issues is the introduction of additional additives. Secondly, the addition of SAP creates an additional financial burden. As two common concrete additives, nano-SiO2 and fly ash have been demonstrated to offer significant advantages in improving the performance of concrete. The involvement of them would contribute to the resolution of the aforementioned issues.

Nano-SiO2 has a high specific surface area and volcanic ash activity, which can markedly enhance the mechanical properties and durability of concrete [7-8]. Concurrently, the elevated activity of nano-SiO2 enables the generation of a greater quantity of hydration products [9]. Because of its spherical particles and filling effect, fly ash can improve the workability and compactness of concrete. At the same time, the potential hydration activity of fly ash also contributes to the growth of long-term strength [10]. The addition of fly ash can effectively utilize the water released by SAP to further densify the concrete structure through secondary hydration reaction. Part of cement in cement concrete is replaced by fly ash, and the overall cost is reduced. The incorporation of both nano-silica and fly ash in SAP internal curing concrete will prove beneficial in the amelioration of SAP-induced pore problems through composite action.

This paper presents a discussion of the mechanical properties of nano-SiO2 and fly ash composite-modified SAP internal curing concrete. By optimising the content of nano-SiO2 and fly ash, the mechanical properties of SAP internal curing concrete can be enhanced. Concurrently, the combined effect of nano-SiO2 and fly ash results in enhanced internal hydration of SAP internal curing concrete. Furthermore, the impact of nano-SiO2 and fly ash on the porosity of concrete was also examined. The incorporation of nano-SiO2 and fly ash into SAP internal curing concrete resulted in an enhancement of the internal pore structure and a reduction in the overall porosity. This study proposes a composite modification strategy combining nano-SiO2 and fly ash to optimise the mechanical properties and pore structure of SAP internal curing concrete. By revealing the synergistic mechanism between the two in promoting hydration reactions, filling effect and microaggregation, it provides a new idea for the development of low-cost, high-performance internal curing concrete.

2. Material and methods

2.1. Materials

The cement used in the experiment was P.O 42.5 ordinary Portland cement. In this test, coarse and fine aggregates that meet the requirements of the specifications were used. Polycarboxylate superplasticizer with a water reduction rate of 30 % was used. The commercially available composite SAP was selected with a particle size range of 100-120 mesh. Commercially available hydrophilic nano-SiO2 was selected, and the relevant parameters were presented in Table 1. The precise composition of the fly ash employed is detailed in Table 3.

Table 1Main technical indexes of nano-SiO2

Purity / % | Average particle size / nm | Specific surface area / m2·g-1 | PH |

≥ 99.8 | 15 | 320 | 6-7 |

2.2. Proportioning of concrete

The design strength of ready-mixed concrete was C40. The design mix ratio had been modified on numerous occasions, and the basic mix ratio of the test was presented in Table 2. In the absence of any consideration of the impact of SAP content, the experiment was conducted with nano-SiO₂ and fly ash as the principal variables. Four types of nano-SiO2 content (0, 1, 2, and 3w%) and four types of fly ash content (0, 10, and 20w%) were selected. The mix proportion of each group was presented in Table 3.

Table 2Basic mix ratio of concrete

w/c | Cement / (kg/m3) | Water / (kg/m3) | Sand / (kg/m3) | Limestone / (kg/m3) | Admixture / (kg/m3) |

0.39 | 382 | 146 | 782 | 1257 | 5.97 |

Table 3Test scheme of each group

Group | Nano-SiO2 (w%) | Fly ash (w%) | Group | Nano-SiO2 (w%) | Fly ash (w%) |

NF-a1 | 0 | 0 | NF-c1 | 2 | 0 |

NF-a2 | 0 | 10 | NF-c2 | 2 | 10 |

NF-a3 | 0 | 20 | NF-c3 | 2 | 20 |

NF-b1 | 1 | 0 | NF-d1 | 3 | 0 |

NF-b2 | 1 | 10 | NF-d2 | 3 | 10 |

NF-b3 | 1 | 20 | NF-d3 | 3 | 20 |

2.3. Experimental procedures

Before sample preparation, nano-SiO2 was pre-dispersed by ultrasonic dispersion method. The ultrasonic dispersion was conducted at a frequency of 40 kHz for a duration of 30 minutes.SAP was added to concrete by dry mixing. The components other than the nano-SiO2 were first dry-mixed. Then the well-dispersed nano-SiO2and mixture of admixture and water were added to continue mixing. After mixing and forming the concrete into moulds, it was placed in a standard curing room for curing. When each group of SAP internal curing concrete specimens were cured for 28 days, they were immediately taken out of the curing room and tested for mechanical properties. According to the “Standard for Testing Methods of Mechanical Properties of Ordinary Concrete” (GB/T50081-2002), the compressive strength and splitting tensile strength of 100 mm×100 mm×100 mm cube specimens was tested by TYE-2000B pressure testing machine. Through the mercury intrusion method, the internal pore structure of each group of SAP internal curing concrete specimens was analyzed. The AutoPore IV 9500 mercury piezometer was used for porosity analysis with a pore size measurement range of 3 nm-360 μm.

3. Results and discussions

3.1. Compressive strength

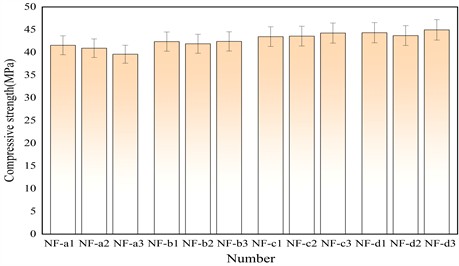

The cube 28 d compressive strength test results of each group of SAP internal curing concrete specimens were presented in Fig. 1. It can be seen from the figure that the compressive strength of the NF-a1 to NF-a3 groups gradually decreased. The relatively slowed hydration reaction of fly ash may result in a reduction in the early strength of the concrete. The compressive strength of NF-b1 to NF-b3 groups showed a fluctuating state. The data indicated a gradual increase in compressive strength for the NF-c1 to NF-c3 groups. Finally, the change trend of compressive strength of NF-d1 to NF-d3 groups was similar to that of group b.

Fig. 128 d compressive strength of concrete specimens in each group

The addition of nano-SiO2 can enhance the bond strength and pore distribution of concrete mixtures at suitable dosages. Furthermore, the combined effect of SAP and nano-SiO2 optimised the internal pore and crack structure of concrete. The internal curing effect of concrete may be enhanced. When nano-SiO2 and fly ash work together, a small amount of fly ash will bring about the strength loss of concrete. However, nano-SiO2 promoted hydration and reduces the negative impact of fly ash. At the same time, they interact with each other and may better play the micro-aggregate effect. The internal structure of SAP internal curing concrete was improved.

3.2. Splitting tensile strength

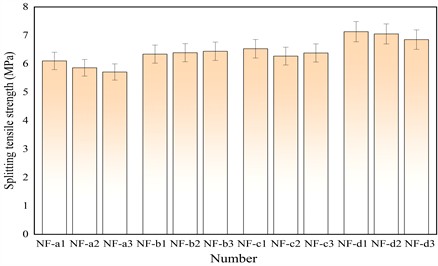

The results of the 28 d cube splitting tensile strength test for each group of SAP internal curing concrete specimens were presented in Fig. 2. As illustrated in the figure, the 28 d splitting tensile strength of the NF-a1 ~ NF-a3 group demonstrated a gradual decline with the incorporation of fly ash. The splitting tensile strength of the NF-b1 to NF-b3 groups showed an increasing trend. When the nano-SiO2was doped at 2 %, the splitting tensile strength of the NF-c1 to NF-c3 groups demonstrates a trend of initially decreasing and then increasing. Finally, there was a small decrease in the split tensile strength of the NF-d1 to NF-d3 groups.

Fig. 228 d Splitting tensile strength specimens in each group

Under the same amount of fly ash, it can be found that the splitting tensile strength of concrete increases slightly with the increase of nano-SiO2 content. Compared with the compressive strength, the effect of nano-SiO2was not significant. The trend of intensity decline can still be clearly seen. Under the combined action of nano-SiO2 and fly ash, although the splitting tensile strength of concrete showed a downward trend, the strength of each group with the same fly ash content increases with the increase of nano-SiO2 content. It can be seen that due to the combined effect of the two, relatively good results were obtained.

3.3. Porosity

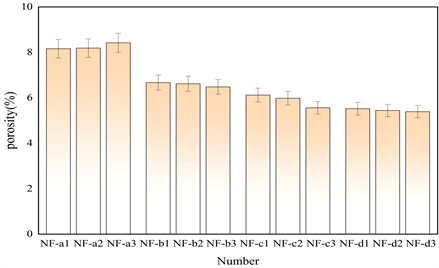

The cubic porosity test results of SAP internal curing concrete specimens in each group were presented in Fig. 3. It can be seen from the diagram that the porosity of NF-a1 to NF-a3 groups gradually increases, and increases with the increase of fly ash content. The porosity of NF-b1 to NF-b3 groups showed a downward trend, which may be due to the incorporation of nano-SiO2 to improve the internal structure of concrete. When 2 % nano-SiO2 was added, the porosity of NF-c1 to NF-c3 groups showed a significant downward trend. Finally, the porosity of the NF-d1 to NF-d3 groups changed more gently, corresponding to its strength development.

Fig. 3Porosity specimens in each group

Under the combined action of nano-SiO2 and fly ash, the porosity of SAP internal curing concrete was improved. Both nano-SiO2 and fly ash had a certain micro-aggregate effect, and they may play a role under appropriate dosage. Meanwhile, the addition of nano-SiO2 promoted the generation of hydration products in concrete. The combined impact of them will serve to mitigate the unfavourable effects associated with the incorporation of fly ash. When the content of nano-SiO2was low, the improvement brought by the combined effect of them was weakened.

4. Conclusions

1) The combined action of nano-SiO2 and fly ash results in an increase in the compressive strength and splitting tensile strength of SAP internal curing concrete, accompanied by a reduction in porosity.

2) The incorporation of fly ash into SAP internal curing concrete results in a reduction in strength and an increase in porosity. The incorporation of nano-SiO2 not only enhances the strength of SAP internal curing concrete, but also optimises the porosity.

3) The incorporation of nano-SiO2 has been demonstrated to enhance the mechanical properties and porosity of composite modified SAP internal curing concrete, thereby mitigating the adverse effects of fly ash.

4) The composite modification of nano-SiO2 and fly ash has been demonstrated to effectively balance the contradiction between strength enhancement and cost control of SAP internal curing concrete. This provides a feasible solution to the technical problem of high porosity of traditional SAP concrete.

References

-

X.-H. Wang, Z.-C. Fang, and L. Zheng, “Effect of dose and types of the water reducing admixtures and superplasticizers on concrete strength and durability behaviour: a review,” Journal of Civil Engineering and Management, Vol. 30, No. 1, pp. 33–48, Jan. 2024, https://doi.org/10.3846/jcem.2024.20145

-

S. Haruna, M. Adamu, Y. E. Ibrahim, M. M. Aliyu, and S. I. Haruna, “Internal curing of ultra-high-performance concrete: A comprehensive overview,” Journal of the Mechanical Behavior of Materials, Vol. 32, No. 1, p. 20220, Mar. 2023, https://doi.org/10.1515/jmbm-2022-0282

-

A. S. Sidhu and R. Siddique, “Review on effect of curing methods on high strength concrete,” Construction and Building Materials, Vol. 438, p. 136858, Aug. 2024, https://doi.org/10.1016/j.conbuildmat.2024.136858

-

K. Wang, K. Dong, J. Guo, and H. Du, “Absorption and Release mechanism of superabsorbent polymers and its impact on shrinkage and durability of internally cured concrete – A review,” Case Studies in Construction Materials, Vol. 21, p. e03909, Dec. 2024, https://doi.org/10.1016/j.cscm.2024.e03909

-

J. Xia, L. Ren, Q. Ren, R. Zhang, C. Gao, and Z. Jiang, “Effect of internal curing with superabsorbent polymers on the compressive strength and shrinkage of concrete with natural volcanic ash,” Journal of Materials in Civil Engineering, Vol. 36, No. 6, p. 04024, Jun. 2024, https://doi.org/10.1061/jmcee7.mteng-16841

-

Y. Zhou et al., “Effects of kaolin-modified superabsorbent polymers on mortar properties,” Journal of Building Engineering, Vol. 79, p. 107755, Nov. 2023, https://doi.org/10.1016/j.jobe.2023.107755

-

A. Ashokan, R. Dhairiyasamy, and S. Rajendaran, “Investigating the influence of nano-silica incorporation on mechanical characteristics of steel fiber-reinforced concrete to mitigate solid waste and environmental contamination,” Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, Vol. 46, No. 1, pp. 131–147, Dec. 2024, https://doi.org/10.1080/15567036.2023.2282146

-

S. Chen, M. Gao, S. Wang, and S. M. Sadeghzadeh, “Benzimidazole-connected microporous conjugated polymers bolstered by dendritic fibrous nanosilica as a significant additive in the context of ultra-high-performance concrete,” Case Studies in Construction Materials, Vol. 21, p. e03561, Dec. 2024, https://doi.org/10.1016/j.cscm.2024.e03561

-

D. Jiang et al., “Internal curing with superabsorbent polymer modified by nano SiO2: Shrinkage mitigation and microstructure refinement,” Cement and Concrete Research, Vol. 175, p. 107353, Jan. 2024, https://doi.org/10.1016/j.cemconres.2023.107353

-

Y. Wang, L. Burris, R. D. Hooton, C. R. Shearer, and P. Suraneni, “Effects of unconventional fly ashes on cementitious paste properties,” Cement and Concrete Composites, Vol. 125, p. 104291, Jan. 2022, https://doi.org/10.1016/j.cemconcomp.2021.104291

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.