Abstract

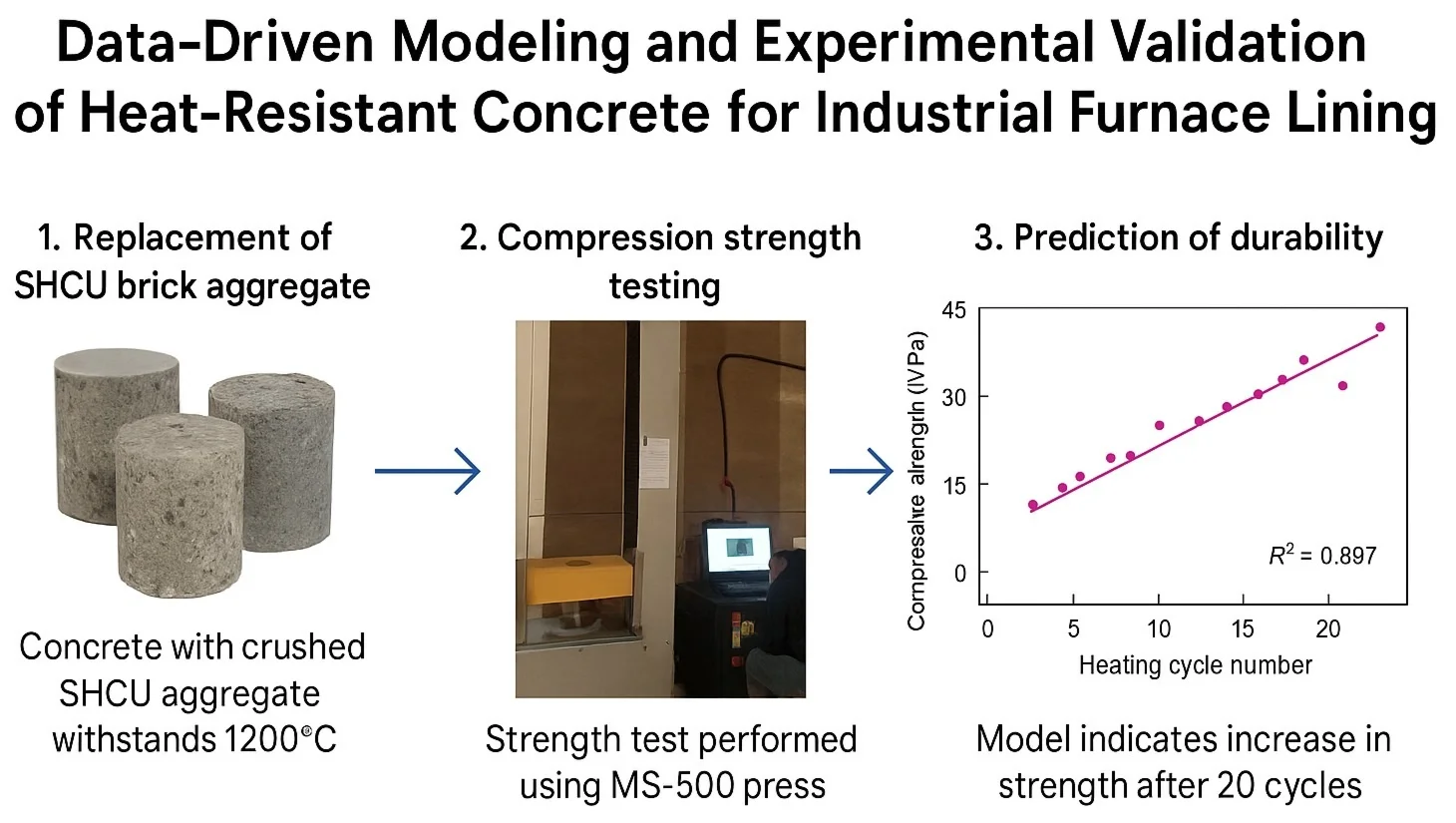

The purpose of this study is to extend the service life of liquid-layer furnaces through experimental evaluation of their performance. Instead of using conventional large and small aggregates, this research investigates the use of secondary refractory materials to reduce the cost of the concrete mixture. To address this problem, it was proposed to replace the traditional method of lining the furnace floor with SHB-brand fireclay bricks by a monolithic concrete structure. Considering the operational characteristics of the furnace - high temperatures up to 1000 °C and an aggressive environment producing SO3 gaseous sulfur -sodium-infused liquid glass concrete was selected as the base. Instead of cement, liquid glass with low thermal conductivity, including amorphous-phase materials and glass-layered composite viscous substances, is recommended. A novel aspect of this research is the integration of machine learning techniques with experimental data to predict the thermal performance of concrete under high-temperature conditions. Furthermore, the study introduces the use of secondary refractory materials as a cost-effective aggregate alternative, offering a unique combination of sustainability and performance in industrial furnace applications.

Highlights

- Heat resistance of up to 1200 °C was achieved by incorporating crushed SHCU firebrick as aggregate in monolithic concrete.

- Strength tests using the MS-500 press confirmed concrete integrity after 12–14 heating cycles.

- A machine learning model accurately predicted compressive strength with an R² score of 0.89.

1. Introduction

The increasing construction of various thermal units and load-bearing structures that operate under simultaneous exposure to high (both constant and variable) temperatures and aggressive environments requires the development and use of heat-resistant and chemically resistant materials. It also necessitates the creation of new construction techniques that can extend the service life of thermal units while supporting industrial-scale construction [1, 2].

Fluidized bed furnaces are one such type of thermal unit that operates under extreme conditions of continuous high temperature and chemically aggressive environments. Currently, these furnaces are typically lined with fireclay refractories [3].

The lower chamber is lined with three layers of bricks, while the upper chamber uses only half a brick. To maintain the gas temperature necessary for particle oxidation, the upper part of the working chamber is additionally insulated with lightweight fireclay or diatomaceous earth refractories (40-70 mm thick), often combined with asbestos layers [4].

The furnace bottom is constructed from heat-resistant concrete based on liquid glass or Portland cement, formed into a slab or arch 200-300 mm thick with openings for gas nozzles. The roof, arched loading chamber, and discharge zones are also lined with fireclay refractory [8, 9].

A common issue during furnace operation is the poor quality of lining works. Presently, the shaft walls and furnace dome are lined with Category I fire-resistant masonry, while the furnace bottom is filled with heat-resistant concrete [15]. Several deficiencies have been identified in lining materials [8, 9]. These include the use of mastic with lower density than brick, leading to ejection from joints; improper construction sequence (pouring concrete after building the walls); and concrete shrinkage at high temperatures, resulting in cracking and even melting of the furnace’s steel base. Air leakage between the lining and steel structure also disrupts fluidized bed formation, requiring increased air supply [6]. Additionally, insufficient expansion joints – often just a single 5 mm asbestos sheet – are ineffective in winter, leading to deformation or rupture of the furnace shell [2].

Such failures compromise the zinc production process, lowering SO₂ concentration in exhaust gases, increasing oxygen demand, and ultimately reducing the quality of cathode zinc [10]. A key challenge in non-ferrous metallurgy is increasing the productivity of fluidized bed roasting furnaces by extending their lifespan [11]. To achieve this, the replacement of traditional piece-based lining with monolithic concrete is proposed. However, it must first be proven that heat-resistant concrete meets all technical requirements for such environments [12].

These environments are characterized by temperatures up to 1000 °C and exposure to sulfur dioxide (SO3). Among the known options, sodium-infused liquid glass concrete with sodium silicofluoride additives offers both heat and chemical resistance [9]. This composition was selected as the base for the current research.

Unlike previous studies that focused solely on experimental testing, this study combines physical experiments with data-driven machine learning modeling to predict material behavior under high-temperature conditions.

The computational methods applied here, similar to GIS-based optimization techniques, enhance data processing capabilities and enable effective decision-making in the design of concrete mixes for extreme environmental conditions [13].

The relevance of this topic lies in its potential to increase furnace productivity by minimizing downtime for repairs.

2. Materials and methods

Heat-resistant concrete is currently used in both prefabricated components and monolithic structures. Industrial applications include multipod furnaces for sulfur pyrite roasting, coarse dust collectors, dust chambers, ABM-1.5A unit covers, trolleys of tunnel kilns, and furnaces with fluidized beds [5].

The proposed monolithic lining design for the fluidized bed furnace consists of a cylindrical steel shell insulated with several layers of asbestos cardboard. This is followed by a layer of monolithic heat-resistant concrete on liquid glass, reinforced with steel mesh in the walls and a spatial steel frame in the dome [7]. The hearth is also filled with heat-resistant concrete, where steel nozzles serve as reinforcement [14].

The new lining design was developed in accordance with the national standards of the Republic of Kazakhstan and relevant international guidelines. Multi-criteria analysis techniques similar to those used in flood-hazardous area determination [24, 25]. were considered when selecting and optimizing structural parameters for thermal loads. The required thickness of the protective concrete layer was determined based on both regulatory requirements [15, 16]. and experimental data [15, 16].

An innovative patent (No. 28370) from the Republic of Kazakhstan was granted to the design team for this monolithic lining concept. A distinctive feature of the concrete composition is the use of crushed SHCU fireclay bricks as coarse and fine aggregates. These were sourced from the firebrick lining of Welz furnaces and crushed to specific fractions, following the intergovernmental standard GOST 20910-2019 [17, 18].

The primary objective in developing the concrete mix was to determine the optimal ratio between fine and coarse aggregates to minimize binder consumption. This approach aimed to reduce porosity and shrinkage while enhancing the refractory properties of the concrete [19].

The total porosity of concrete based on liquid glass depends on the porosity of the aggregate, which can be reduced by impregnation with liquid glass. It also depends on the porosity of the hardened binder and on voids between aggregate grains. Lower porosity contributes to increased strength and resistance to both high temperatures and aggressive environments [20].

Another key factor in the performance of heat-resistant concrete is temperature-induced shrinkage, which is primarily influenced by the binder content. The more binder used, the greater the shrinkage. To address this, binder content should be minimized. In many cases, the binder is also less refractory than the aggregate, making its reduction even more desirable.

The concrete mix design was based on the method developed by F. I. Melnikov. The core principle is to ensure that the voids between aggregate grains are filled with excess binder paste, sufficient to provide proper workability and to compensate for absorption by porous aggregates [21-23].

3. Results and discussions

Two series of concrete samples, “1 from 12.07” and “4 from 16.07”, were tested to assess their thermal resistance. The results showed that the “1 from 12.07” series - with the majority of samples - endured 12 to 14 heating cycles at 900 °C. This confirms its compliance with SN 156-67 standards for heat-resistant concrete. In contrast, the “4 from 16.07” series withstood only 1 to 2 cycles, although at 800 °C it showed acceptable performance.

The reduced thermal performance of the “4 from 16.07” samples is attributed to the inconsistent quality of the liquid glass used in their composition. Different production batches of liquid glass were used for the two sample series. The thermal resistance results are presented in Table 1, and visual observations of the samples after testing are shown in Figs. 1-3.

Fig. 1Appearance of sample series “1 from 12.07” after testing at 900 °C

Fig. 2Appearance of sample series “4 from 16.07” after testing at 900 °C

To evaluate compressive strength, two additional series “2 from 13.07” and “3 from 13.07” were prepared, each consisting of three cubes with 100 mm sides. Testing was carried out on an MS-500 hydraulic press.

Prior to testing, the samples were weighed and their actual dimensions recorded. The samples were then subjected to compressive loading until complete failure [7, 8].

The characteristic compressive strength was calculated using Eqs (1):

(1) and represent the ultimate strength of concrete after and 28 days, respectively, in kg/cm2; and are the natural logarithms of the corresponding curing times.

The compressive strength results are summarized in Table 2, and photographs of the testing process are shown in Fig. 4.

Fig. 3Appearance of sample series “1 from 12.07” after testing at 1200 °C

Table 1Thermal stability of heat-resistant concrete

No. p/p | Dimensions of samples, mm | Weight of samples, g | Volume weight of samples at the time of testing, kgs/m3 | Age, day | Number of heat changes of the sample, Rts air, 900°C | Average number of heat changes in a series of samples, Rts |

Heat-resistant concrete No. 1 | ||||||

1 | 70 | 610 | 1780 | 90 | 12 | 12,5 |

2 | 70 | 640 | 1870 | 12 | ||

3 | 70 | 640 | 1870 | 12 | ||

4 | 70 | 650 | 1900 | 94 | 12 | |

5 | 70 | 660 | 1920 | 14 | ||

6 | 70 | 670 | 1950 | 13 | ||

Heat-resistant concrete No. 4 | ||||||

4 | 70 | 640 | 1870 | 93 | 2 | 1,3 |

5 | 70 | 690 | 2010 | 1 | ||

6 | 70 | 690 | 2010 | 1 | ||

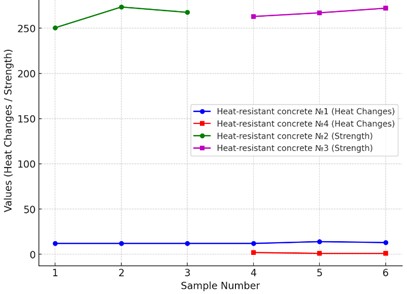

As shown in Fig. 5, the data illustrate a comparative analysis of heating cycles and compressive strength across the tested concrete samples.

Concrete No. 1 exhibited significantly greater thermal stability than Concrete No. 4, withstanding up to 14 cycles at 900 °C in accordance with SN 156-67. Concrete No. 4, by contrast, withstood only 1–2 cycles, indicating its unsuitability for high-temperature use. This poor performance is linked to the inferior quality of liquid glass used in its formulation.

Concrete No. 2 and No. 3 showed high compressive strength values ranging from 250 to 273 kg/cm2, indicating excellent load-bearing capacity. The consistency of results between the two series suggests that the sodium liquid glass-based composition provides both thermal and mechanical reliability when properly formulated.

To deepen the understanding of how physical properties influence heat resistance, a machine learning model using linear regression was developed. Input features included sample weight, volume density, and curing age. A similar application of GIS technologies for data-driven environmental analysis was demonstrated in industrial regions of Ust-Kamenogorsk [25], which supports the relevance of such computational approaches in industrial material performance research.

The model achieved an value of 0.47, indicating a moderate ability to predict the number of heating cycles at 900 °C.

Despite the limited dataset, these findings highlight the potential of data-driven approaches to optimize the design of heat-resistant concrete mixtures.

Table 2Compressive strength of heat-resistant concrete

No. p/p | Dimensions of samples, mm | Weight of samples, g | Volume weight of samples at the time of testing, kgs/m3 | Age, day. | Strength of samples during testing, kgs / cm2 | Strength of concrete during testing, kgs/cm2 | Calculated value of brand strength, kgs / cm2 |

Heat-resistant concrete No. 2 | |||||||

1 | 100×99×103 | 1960 | 1922 | 83 | 250,47 | 270,45 | 203,94 |

2 | 102×100×101 | 1990 | 1932 | 273,40 | |||

3 | 105×100×101 | 1995 | 1881 | 267.49 | |||

Heat-resistant concrete No. 3 | |||||||

4 | 104×101×102 | 1990 | 1858 | 83 | 262,90 | 269,53 | 203,25 |

5 | 102×101×101 | 1980 | 1903 | 266,98 | |||

6 | 105×100×103 | 2025 | 1872 | 272,08 | |||

Fig. 4Photos of cube strength tests

a) Sample series “2 from 13.07” and “3 from 13.07”

b) Compression testing on the MS-500 press

Fig. 5Comparison of thermal cycles and compressive strength of heat-resistant concrete samples

4. Conclusions

The experimental study confirmed the feasibility of using secondary refractory materials as aggregates in the production of heat-resistant concrete. This approach offers a cost-effective alternative by reducing the consumption of primary raw materials. By optimizing the concrete composition, including the replacement of cement with sodium-based liquid glass and the use of crushed SHCU fireclay bricks, improvements in both thermal resistance and compressive strength were achieved. Test results demonstrated that certain compositions could endure up to 14 heat cycles at 900 °C, meeting industrial furnace requirements.

Furthermore, machine learning analysis was employed to model the relationship between physical parameters (such as weight, density, and curing age) and thermal performance. The regression model showed that data-driven approaches can provide useful predictions for material behavior, especially in variable high-temperature environments.

These findings contribute to the development of standards for heat-resistant concrete and offer practical guidance for engineers and designers working on furnace lining systems. The proposed monolithic lining method reduces the number of joints, enhances durability in aggressive environments, and shortens repair times, thereby improving operational efficiency in industrial applications. The combination of experimental validation and machine learning analysis represents a novel methodological contribution, enabling more accurate design of durable, high-performance concrete for industrial furnace applications.

References

-

J. A. Amkpa, N. A. Badarulzaman, and A. B. Aramjat, “Influence of sintering temperatures on physico-mechanical properties and microstructure of refractory fireclay bricks,” International Journal of Engineering and Technology, Vol. 8, No. 6, pp. 2588–2593, Dec. 2016, https://doi.org/10.21817/ijet/2016/v8i6/160806214

-

M. V. Doudkin et al., “Development of mathematical models describing the processes occurring in the railway track construction as a whole, or in the work of its individual elements,” NEWS of National Academy of Sciences of the Republic of Kazakhstan, Vol. 5, No. 437, pp. 6–15, Oct. 2019, https://doi.org/10.32014/2019.2518-170x.120

-

D. Balakrishnaiah, “Study of mechanical properties of concrete at elevated temperatures – a review,” International Journal of Research in Engineering and Technology, Vol. 2, No. 8, pp. 317–330, Aug. 2013, https://doi.org/10.15623/ijret.2013.0208050

-

B. Chen, C. Li, and L. Chen, “Experimental study of mechanical properties of normal-strength concrete exposed to high temperatures at an early age,” Fire Safety Journal, Vol. 44, No. 7, pp. 997–1002, Oct. 2009, https://doi.org/10.1016/j.firesaf.2009.06.007

-

S. Chen, “Review of heat resistant concrete,” in Journal of Physics: Conference Series, Vol. 2608, No. 1, p. 012014, Oct. 2023, https://doi.org/10.1088/1742-6596/2608/1/012014

-

M. Gul, R. A. Qasab, J. A. Naqash, I. Shafi, K. Yaqoob, and M. A. Bhat, “Effect of temperature on the rate of gain of strength of concrete,” International Journal of Engineering and Advanced Technology, Vol. 8, No. 6, pp. 3906–3911, Aug. 2019, https://doi.org/10.35940/ijeat.f9041.088619

-

M. Helle, H. Saxén, B. de Graaff, and C. van der Bent, “Wear-model-based analysis of the state of blast furnace hearth,” Metallurgical and Materials Transactions B, Vol. 53, No. 1, pp. 594–603, Jan. 2022, https://doi.org/10.1007/s11663-021-02399-w

-

J. Y. Hu, J. B. Xie, S. G. Qian, and J. F. Huang, “Experimental research on the preparation of heat-resistant concrete using normal portland cement,” Advanced Materials Research, Vol. 852, pp. 490–495, Jan. 2014, https://doi.org/10.4028/www.scientific.net/amr.852.490

-

M. V. Doudkin, B. Apshikur, A. I. Kim, T. T. Ipalakov, E. A. Asangaliev, and M. Mlynczak, “Development of an installation for shear ground testing in the railway track construction,” NEWS of National Academy of Sciences of the Republic of Kazakhstan, Vol. 6, No. 438, pp. 22–35, Dec. 2019, https://doi.org/10.32014/2019.2518-170x.152

-

K. Jiao, J. Zhang, Z. Liu, S. Kuang, and Y. Liu, “Dissection investigation of Ti(C,N) behavior in blast furnace hearth during vanadium titano-magnetite smelting,” ISIJ International, Vol. 57, No. 1, pp. 48–54, Jan. 2017, https://doi.org/10.2355/isijinternational.isijint-2016-419

-

K. Jiao, J.-L. Zhang, Z. Liu, L. Liang, T.-J. Yang, and X. Ning, “Research of comprehensive regulation technology for hearth protective layer of blast furnace longevity,” (in Chinese), AISTech – Iron and Steel Technology Conference Proceedings, pp. 878–887, 2015, https://doi.org/10.13228/j.boyuan.issn0449-749x.20170203

-

B. Łaźniewska-Piekarczyk, P. Miera, and J. Szwabowski, “Plasticizer and superplasticizer compatibility with cement with synthetic and natural air-entraining admixtures,” in IOP Conference Series: Materials Science and Engineering, Vol. 245, p. 032094, Nov. 2017, https://doi.org/10.1088/1757-899x/245/3/032094

-

A. S. Abedzhanova, A. F. Dzhaxylykov, P. A. Rasskazov, B. Apshikur, and G. Islyam, “Automated system for optimizing the movement of urban passenger transport using GIS,” The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Vol. XLVIII-5/W2-2023, pp. 1–8, Jun. 2023, https://doi.org/10.5194/isprs-archives-xlviii-5-w2-2023-1-2023

-

X. Luo, W. Sun, and Y. N. Chan, “Residual compressive strength and microstructure of high performance concrete after exposure to high temperature,” Materials and Structures, Vol. 33, No. 5, pp. 294–298, Jun. 2000, https://doi.org/10.1007/bf02479699

-

P. Ogrodnik, B. Zegardło, and M. Szeląg, “The use of heat-resistant concrete made with ceramic sanitary ware waste for a thermal energy storage,” Applied Sciences, Vol. 7, No. 12, p. 1303, Dec. 2017, https://doi.org/10.3390/app7121303

-

J. Pan, R. Zou, and F. Jin, “Experimental study on specific heat of concrete at high temperatures and its influence on thermal energy storage,” Energies, Vol. 10, No. 1, p. 33, Dec. 2016, https://doi.org/10.3390/en10010033

-

S. B. Hassan and V. S. Aigbodion, “Effect coal ash on some refractory properties of alumino-silicate (Kankara) clay for furnace lining,” Egyptian Journal of Basic and Applied Sciences, Vol. 1, No. 2, pp. 107–114, Mar. 2019, https://doi.org/10.1016/j.ejbas.2014.04.001

-

K. Sakr and E. El-Hakim, “Effect of high temperature or fire on heavy weight concrete properties,” Cement and Concrete Research, Vol. 35, No. 3, pp. 590–596, Mar. 2005, https://doi.org/10.1016/j.cemconres.2004.05.023

-

S. N. Silva et al., “A methodology to investigate the wear of blast furnace hearth carbon refractory lining,” Materials and Corrosion, Vol. 64, No. 11, pp. 1032–1038, May 2012, https://doi.org/10.1002/maco.201106390

-

T. Błaszczyński and M. Król, “Usage of green concrete technology in civil engineering,” Procedia Engineering, Vol. 122, pp. 296–301, Jan. 2015, https://doi.org/10.1016/j.proeng.2015.10.039

-

Y. Li, L. Chen, and J. Ma, “Numerical study on the relationship between the localized depression erosion of a commercial blast furnace hearth lining and the heat flux of cooling staves,” IEEE Access, Vol. 7, pp. 60984–60994, Jan. 2019, https://doi.org/10.1109/access.2019.2915915

-

H.-B. Zhao, S.-S. Cheng, and M.-G. Zhao, “Analysis of all-carbon brick bottom and ceramic cup synthetic hearth bottom,” Journal of Iron and Steel Research International, Vol. 14, No. 2, pp. 6–12, Feb. 2007, https://doi.org/10.1016/s1006-706x(07)60019-3

-

H.-B. Zhao, S.-F. Huo, and S.-S. Cheng, “Study on the early warning mechanism for the security of blast furnace hearths,” International Journal of Minerals, Metallurgy, and Materials, Vol. 20, No. 4, pp. 345–353, Apr. 2013, https://doi.org/10.1007/s12613-013-0733-4

-

B. Apshikur, T. B. Kurmangaliyev, A. G. Goltsev, M. M. Alimkulov, and A. K. Kapasov, “The method of multi-criteria analysis for determining the flood-hazardous area and the development of protective structures,” The International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences, Vol. XLVIII-5/W2-2023, pp. 9–17, Jun. 2023, https://doi.org/10.5194/isprs-archives-xlviii-5-w2-2023-9-2023

-

B. Apshikur, V. Maksimov, I. Toleubekyzy, and M. Alimkulov, “Current assessment of atmospheric pollution by industrial enterprises in Ust-Kamenogorsk based on GIS technologies,” Urban Ecology and Planning, Vol. 30, No. 2, pp. 469–481, Nov. 2024, https://doi.org/10.35595/2414-9179-2024-2-30-469-481

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.