Abstract

The object of the study is the interaction of the electric locomotive wheel pair and the rail. The subject of the research is the wheel resource. The paper proposes a model for calculating the resource mileage of the electric locomotive wheel pair. The basis of the model is the determination of contact stresses in the wheel pair. The proposed calculation model, when changing the input data, can be used to determine the resource of various wheel pairs and traffic safety, and resource savings.

Highlights

- The analysis of the influence of the technical condition of wheelsets on the safety of operation of traction rolling stock is carried out.

- A calculation model has been developed to determine the life of locomotive wheelsets based on contact stresses.

- As a result of the calculations, graphs of the dependence of contact stresses in the zone of interaction between the wheel and the rail under various loads were constructed.

- The main factors affecting the wear and service life of wheelsets have been identified.

1. Introduction

Improving the material and technical base of the railway of Uzbekistan is one of the main tasks of the economic reforms carried out in the Republic [1]. Correct calculation of the resource of locomotive wheel pairs will increase the safety of transportation, enhance the authority of the company “Uzbekistan Temir Yollari” and save foreign currency. The interaction of the rail with the wheel pair of the locomotive is the basis of the movement of the train. It is impossible to avoid wear of the “wheel-rail” system, since when the wheel rolls along the rail, there is not only rolling friction, but also sliding friction. Wear of the wheel pair of an electric locomotive occurs both on straight and curved sections of the track. The resulting contact stresses on the working surfaces of the wheel pair are the cause of many defects: sliders, chips, cavities and many others. More than 30 % of the fuel and energy resource is spent on wear, the energy efficiency of railways suffers.

For the amount of wear in all countries of the world, standard measures are taken into account: changing the profile of the wheel and track, lubrication, changing the metal, changing the radius of curvature of the track. None of the methods solves the problem. The solution to the problem can be found only using mathematical methods for studying the wear process and generally accepted estimates of contact stresses in the contact of the wheel and rail.

A large number of works have been conducted and published on this topic, both by scientists from the CIS countries and in scientific research [2-6], which have both disadvantages and advantages. The main disadvantage is that the calculation is carried out based on the initially adopted contact area, but it changes during wear.

The purpose of the study is to create a calculation model for predicting resources taking into account changes in the contact area of the wheel pair with the rail. Wear forecast that prevents the ceiling from shifting from the track.

The scientific novelty of this study is that for the first time a comprehensive method has been developed to determine the life of wheel sets of locomotives operated in the climatic and operational conditions of the railways of Uzbekistan and Central Asian countries. As a result of the analysis of the technical condition of the wheelsets during the operation of locomotives, new diagnostic parameters and criteria for assessing the remaining service life are proposed. This makes it possible to increase forecasting accuracy and improve locomotive maintenance schedules.

2. Results

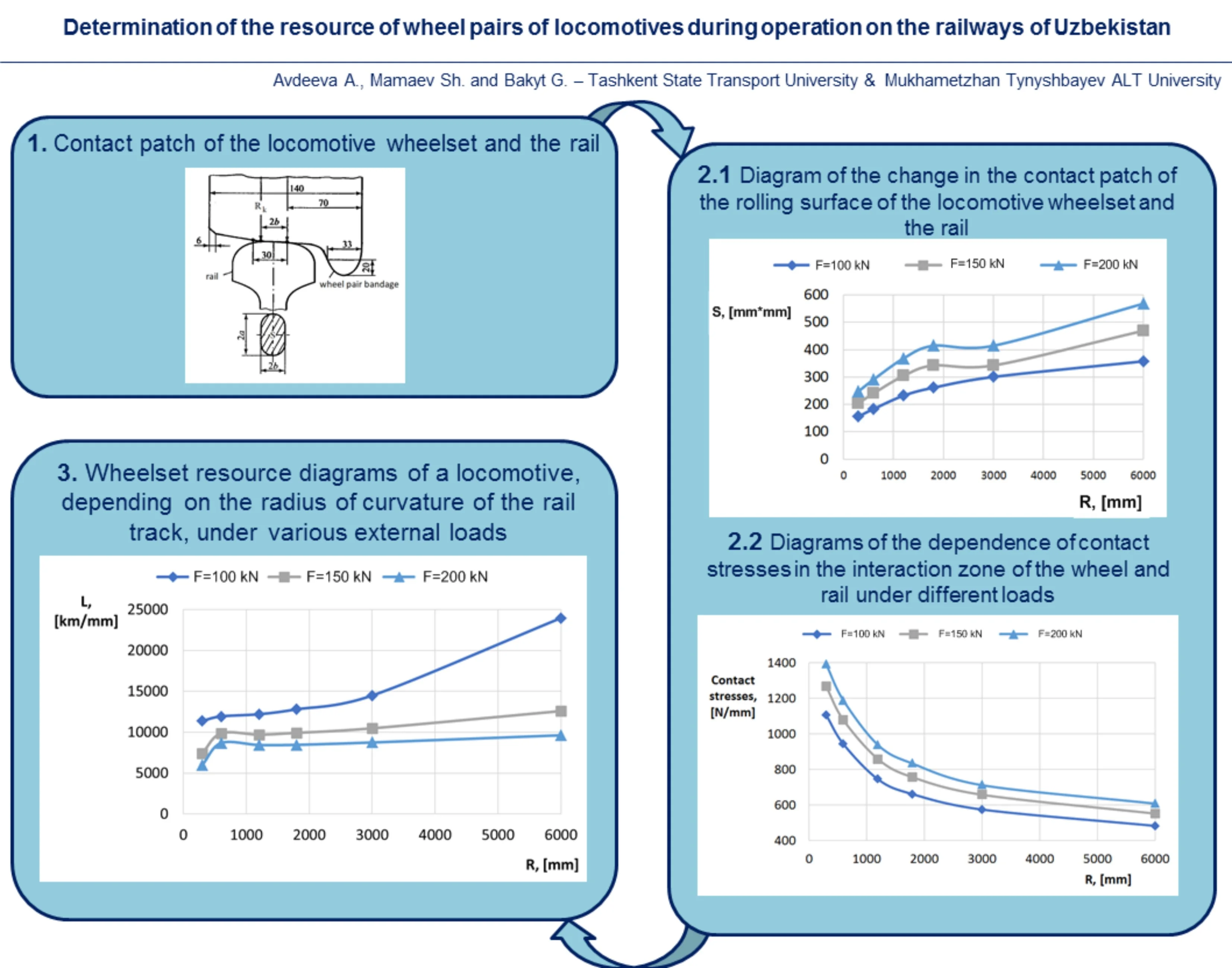

The calculation model for contact stresses and the resource of the wheel pair is based on the formulas of the theory of contact stresses for the model of cylinders with mutually perpendicular axes. The destruction of the surface layers of the tire material in the contact patch area of the tire and the rail is determined by the formula: , where a and b are the dimensions of the semi-axles of the contact areas (Fig. 1).

We divide the contact area into three zones: within the first area , contact stresses occur that are less than the yield strength of wheel steel , so there is no wear. Within the second area S2, contact stresses do not exceed the tensile strength , and destruction by peeling and shearing occurs. For each revolution of the wheel along the rail, a thin film of steel material comes off, with a thickness of:

where 2.52∙10-6 mm is the diameter of one iron atom. Within the third area S3, the peeling of the contact surface of the thin film occurs for each revolution of the wheel relative to the rails with a thickness of:

The total contact area consists of three parts:

Fig. 1Contact patch of the locomotive wheelset and the rail

With a linearly increasing function along the width and length of the contact area to its center of gravity, we obtain formulas for calculating the areas:

where is the value of the interaction area, the radius of the wheel and the rail ; is the value of the contact stress, the radius of the wheel and the rail . The maximum contact stress at a point passing through the center of the contact ellipse is determined by the formula:

where: is the Poisson ratio (selected from reference materials), is the modulus of elasticity (selected from reference materials), is the coefficient depending on the ratio of the radii of curvature of the wheel and rail /, which is selected from ready-made tables, according to reference materials, and is a dimensionless value (Table 1); is the load in the contact zone, which takes into account static and dynamic loads.

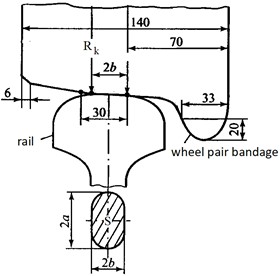

Fig. 2Diagram of the change in the contact patch of the rolling surface of the locomotive wheelset and the rail

Table 1The value of the coefficient, depending on the ratio of the radii of curvature of the wheel

, mm | 300 | 600 | 1200 | 1800 | 3000 | 6000 |

/ | 0.479 | 0.958 | 0.519 | 0.3472 | 0.21 | 0.1042 |

0.972 | 1.0 | 0.9696 | 0.9409 | 0.89 | 0.7879 |

For calculations of a specific section of the track, the profile is determined by curvature. The calculation of contact stresses is made for each curvature value separately. In accordance with the rules for the technical operation of railways of the Republic of Uzbekistan, at speeds of up to 120 km/h, the maximum possible wear is 7 mm by the thickness of the tire. The full calculation of the resource of the wheel pair is divided into seven parts - each part corresponds to the wear of the tire by a thickness of 1 mm. Each part is determined by the formula:

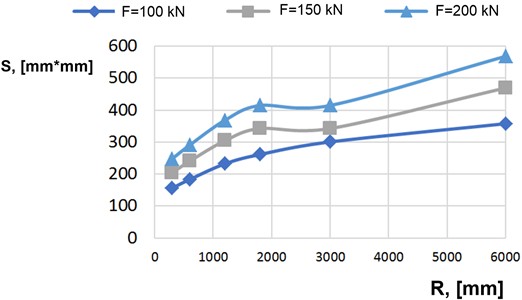

Fig. 3Diagrams of the dependence of contact stresses in the interaction zone of the wheel and rail under different loads

The total mileage is determined as the sum of the parts:

The intensity of wear of the wheel surface is determined by the formula:

where is the wear in millimeters at each stage of operation.

The initial data for the calculations are taken from regulatory documents [7-9]. The article presents numerical calculations for the Tashkent-Khavast test site. The radius of the new wheel tread of the Uzbekistan electric locomotive in operation, manufactured at the Chardzhou Electric Locomotive Plant in China, according to the standard, 625 mm, the wheel tread diameter 1250 mm. The diameter of the iron molecule is 2.52∙10-6 mm. The radii of curvature of the rails on the Uzbekistan test sites are in the range of (300-6000) mm. Fig. 2 shows the diagrams of the change in the contact patch of the locomotive wheelset and the rail for vertical loads of 100 kN, 150 kN, 200 kN.

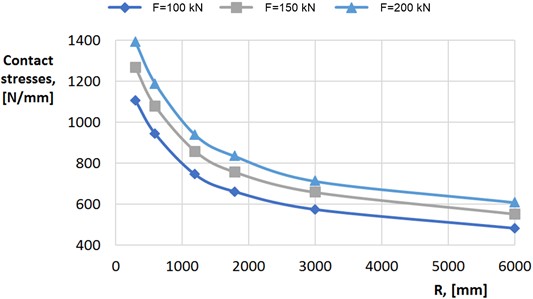

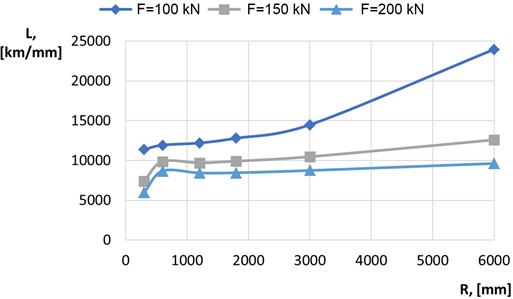

Fig. 4Wheelset resource diagrams of a locomotive, depending on the radius of curvature of the rail track, under various external loads

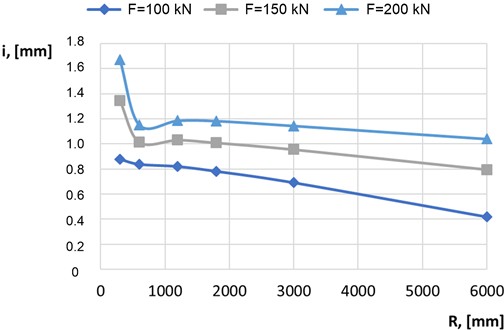

Fig. 3 shows the diagrams of the dependence of contact stresses in the interaction zone of the wheel and rail under various loads, depending on the curvature of the track. It is evident from the diagram that the maximum values of contact stresses are achieved at a minimum radius of curvature of the rails 300 m, and the greater the total load, the greater the contact stresses. Fig. 4 shows the diagrams of the resource of the locomotive wheelset, depending on the radius of curvature of the track, under various external loads. This diagram is compiled for a specific Tashkent-Khavast polygon. Similarly, it is possible to calculate the resource of the locomotive wheelset for any section of the track. Fig. 5 shows the diagrams of the dependence of the intensity of wheel wear, depending on the radius of curvature of the track for various loads for the above section. The calculation model proposed in the article makes it possible to calculate the resource of the locomotive wheelset, taking into account its gradual change in profile.

Fig. 5Diagrams of the dependence of the intensity of wheel wear, depending on the radius of curvature of the rail track for different loads

3. Discussions

The results of the study confirm a significant degree of influence of operating conditions on the life of locomotive wheelsets. As a result of the analysis, it was found that the standard methods for estimating the residual resource used in a number of countries do not take into account the specific factors characteristic of railways with high temperature deviations, variable track condition and operational load, which is typical for railways in Uzbekistan.

Sudden temperature fluctuations, the presence of dust and sand, as well as the characteristics of the track profile, significantly affect the wear rate of wheelsets. The use of new diagnostic criteria makes it possible to identify critical points and stages of defect development.

The implementation of the proposed approach requires updating the system for monitoring the technical condition of rolling stock, including the introduction of automated diagnostic systems and data collection on the dynamic characteristics of wheelsets in real-world operating conditions.

The use of these monitoring technologies in real conditions will make it possible to identify defects in a timely manner and take measures to eliminate them, which will ultimately increase the safety and reliability of railway rolling stock.

4. Conclusions

1) A calculation model is proposed for determining the resource of a locomotive wheel pair through contact stresses, taking into account the gradual change in the contact area of the wheel and rail.

2) The calculation results are already being used at the Uzbekistan repair depot to change the existing repair and maintenance regime for locomotive wheel pairs.

3) The main factors affecting the wear and service life of wheelsets have been identified, among which the intensity of vertical and horizontal loads, temperature fluctuations and the profile of the railway track are of the greatest importance.

4) The results obtained can be used in the development of regulatory and technical documentation and maintenance programs for the locomotive fleet in countries with similar operational characteristics.

References

-

“O‘zbekiston Respublikasi temir yo‘l transporti sohasini tubdan isloh qilish chora-tadbirlari to‘g‘risida.” O‘zbekiston Respublikasi Prezidentining qarori. https://lex.uz/ru/docs/6631604

-

S. Abdullayev, N. Tokmurzina, and G. Bakyt, “The determination of admissible speed of locomotives on the railway tracks of the republic of kazakhstan,” Transport Problems, Vol. 11, No. 1, pp. 61–68, Jan. 2016, https://doi.org/10.20858/tp.2016.11.1.6

-

K. Zhussupov, A. Toktamyssova, S. Abdullayev, G. Bakyt, and M. Yessengaliyev, “Investigation of the stress-strain state of a wheel flange of the locomotive by the method of finite element modeling,” Mechanics, Vol. 24, No. 2, pp. 174–181, May 2018, https://doi.org/10.5755/j01.mech.24.2.17637

-

N. Bosso, M. Magelli, and N. Zampieri, “Simulation of wheel and rail profile wear: a review of numerical models,” Railway Engineering Science, Vol. 30, No. 4, pp. 403–436, Aug. 2022, https://doi.org/10.1007/s40534-022-00279-w

-

T. Licentiate and J. Lundmark, “Rail grinding and its impact on the wear of wheels and rails,” Lulea University of Technology, 2023.

-

Y. Zeng, C. Shen, A. Núñez, R. Dollevoet, W. Zhang, and Z. Li, “An interpretable method for operational modal analysis in time-frequency representation and its applications to railway sleepers,” Structural Control and Health Monitoring, Vol. 2023, pp. 1–26, Jul. 2023, https://doi.org/10.1155/2023/6420772

-

“Wheel sets of traction rolling stock of 1520 mm gauge railways Operation, maintenance and repair Manual.” KMBSH.667120.001RE. http://tehnod.ru/mbsh.

-

M. O. Mussabekov, G. B. Bakyt, A. M. Omirbek, E. Brumerčíková, and B. Buková, “Shunting locomotives fuel and power resources decrease,” in MATEC Web of Conferences, Vol. 134, p. 00041, Nov. 2017, https://doi.org/10.1051/matecconf/201713400041

-

S. Abdullayev, G. Imasheva, N. Tomkurzina, N. Adilova, and G. Bakyt, “Prospects for the use of gondola cars on bogies of model ZK1 in the organization of heavy freight traffic in the Republic of Kazakhstan,” Mechanics, Vol. 24, No. 1, pp. 32–36, Feb. 2018, https://doi.org/10.5755/j01.mech.24.1.17710

-

M. Turakulov, N. Tursunov, and S. Yunusov, “Steeling of synthetic cast iron in induction crucible furnace taking into account consumption rate of carburizers,” in E3S Web of Conferences, Vol. 401, p. 05012, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105012

-

T. Tursunov, N. Tursunov, and T. Urazbayev, “Investigation of heat exchange processes in the lining of induction furnaces,” in E3S Web of Conferences, Vol. 401, p. 05029, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105029

-

M. Turakulov, N. Tursunov, and S. Yunusov, “New concept of cast iron melting technology in induction crucible furnace,” in E3S Web of Conferences, Vol. 401, p. 01060, Jul. 2023, https://doi.org/10.1051/e3sconf/202340101060

-

O. Toirov and N. Tursunov, “Efficiency of using heat-insulating mixtures to reduce defects of critical parts,” in E3S Web of Conferences, Vol. 401, p. 05018, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105018

-

D. Valieva, S. Yunusov, and N. Tursunov, “Study of the operational properties of the bolster of a freight car bogie,” in E3S Web of Conferences, Vol. 401, p. 05017, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105017

-

L. Kuchkorov, N. Tursunov, and A. Avdeeva, “Improving physical and mechanical properties of bentonite clay from Navbahar clay deposit,” in E3S Web of Conferences, Vol. 401, p. 05020, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105020

-

U. Rakhimov and N. Tursunov, “Development of technology for high-strength cast iron for manufacturing D49 head of cylinder,” in E3S Web of Conferences, Vol. 401, p. 05013, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105013

-

T. Urazbayev, N. Tursunov, and T. Tursunov, “Steel modification modes for improving the cast parts quality of the rolling stock couplers,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060015, Jan. 2024, https://doi.org/10.1063/5.0197361

-

U. T. Rakhimov, N. K. Tursunov, and S. E. Tursunov, “Improvement of production technology for spheroidal graphite cast iron with increased strength,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060024, Jan. 2024, https://doi.org/10.1063/5.0197475

-

S. R. Seydametov, N. K. Tursunov, and S. P. Alimukhamedov, “Development of out-of-furnace steel treatment technology for the manufacture of railroad transport parts,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060022, Jan. 2024, https://doi.org/10.1063/5.0197429

-

U. Ziyamukhamedova et al., “Investigating friction and antiwear characteristics of organic and synthetic oils using h-BN nanoparticle additives: a tribological study,” Lubricants, Vol. 12, No. 1, p. 27, Jan. 2024, https://doi.org/10.3390/lubricants12010027

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.