Abstract

In order to improve the anti-cracking performance of the semi-rigid base and reduce the maintenance cost of the semi-rigid base, this paper adopts the orthogonal test method to study the influences of the multi-dimensional cementitious composite system, the type of SAP, the dosage of SAP and additional water intake of SAP on the mechanical properties and the dry shrinkage performance of the semi-rigid base of the aeolian sand. The test data of strength index and shrinkage index were analysed by extreme difference analysis and analysis of variance respectively, and the results showed that when the cement: fly ash is 1:4, the cementitious material: aggregate is 17:83, the aeolian sand replaces 12 % of fine aggregates, the SAP type is composite, the SAP dosage is 0.05 %, and the additional water intake of SAP is 20 times in order to get the optimal internal curingprogramme, and also provides a theoretical basis for the further application of aeolian sand in semi-rigid subgrade.

1. Introduction

In recent years, with the steady progress of the Western Development Strategy and the “Belt and Road” Initiative, the economic development and strategic position of the Northwest Desert Region have become more and more prominent, and it has become the main battlefield of China’s transport infrastructure construction. However, due to the scarcity of raw materials and complex climate environment in the desert area, coupled with the global scarcity of natural sand and gravel resources, the construction process of desert highway has resulted in high energy consumption, high carbon emissions and other problems, which hindered the process of highway construction in the desert area. However, if the unique sand resources in desert areas can be used to build roads, on the one hand, it can control the sand damage and reduce the harm of wind and sand, and on the other hand, it can speed up the construction progress of road building in desert areas and drive the local economic development [1].

For a long time, influenced by the design concept of “strong base and thin surface”, the structure of road grass-roots level in China is mainly based on semi-rigid base, which has the excellent characteristics of high strength and good water stability, and is widely used in the construction of high-grade highways in China [2-3]. However, the semi-rigid base is highly sensitive to temperature and humidity changes, and it is very easy for the temperature and humidity changes to lead to cracks in the strength development of the semi-rigid base. Therefore, it is of great significance to study the anti-cracking performance of semi-rigid base [4]. The traditional way of road base curing is mainly based on sprinkling and wrapping, but the desert area is scarce in water resources, and the use of sprinkling to maintain the road greatly increases the cost of road construction. Existing studies have shown that the addition of super absorbent polymer (SAP) to the cementitious system can form a ‘micro-reservoir’ inside the structure of the cementitious system, maintain the internal humidity of the cementitious system, effectively inhibit the risk of early shrinkage and cracking of the cementitious system, and improve the durability and structural stability of the cementitious system [5-6].

Based on this, in order to improve the problems of difficult construction, lack of raw materials and insufficient maintenance of road subgrade in the desert area, this paper adopts the SAP internal curing program to construct the internal curing system of semi-rigid base in the desert area, which is intended to improve the shrinkage and cracking of semi-rigid base in the desert area under the desert climate, and to increase the anti-cracking and durability of semi-rigid base in the desert area. The expected results will provide theoretical basis and practical support for the popularisation and application of aeolian sand in road subgrade.

2. Materials and method

2.1. Materials

The aeolian sand used in this study is selected from the south of Mao Wusu Desert, with reference to the specification “Aggregate Test Procedure for Highway Engineering” (JTG 3432-2024), it is known that its particle size is distributed between 0.075-0.3 mm by dry sieving method, and the aggregate is selected from limestone crushed stone, and the engineering characteristics such as crushing value, needle flake content and apparent density are tested with reference to the “Test Procedure for Aggregate in Highway Engineering” (JTG 3432-2024), and the test results are shown in Table 1. The cement was ordinary silicate cement P O 42.5, and the fly ash was Class III fly ash, and the test results of its various technical properties are shown in Table 2. The commercially available ionic SAP (No. SAP-AA) and non-ionic SAP (No. SAP-SA), as well as the composite SAP (No. SAP-NA) independently produced by the laboratory, were used in the range of 80-100 mesh, and their performance indicators are shown in Table 3.

Table 1Aggregate engineering properties test results

Performance index | Particle size / mm | ||

2.36-4.75 | 4.75-9.5 | 9.5-26.5 | |

Crushing value (%) | 19.20 | 17.8 | 20.0 |

Needle like content (%) | 14.20 | 13.5 | 12.0 |

Water absorption rate (%) | 0.78 | 0.38 | 0.22 |

Apparent density (g·cm-3) | 2.64 | 2.71 | 0.22 |

Table 2Fly ash technical performance test results

SiO2 | Al2O3 | Fe2O3 | MgO | Firing vector / % | 0.3 mm pass rate / % | 0.5 mm pass rate / % |

47.3 | 29 | 18.7 | 3.01 | 3.51 | 99.4 | 84.5 |

Table 3SAP performance test metrics

Performance indicators | SAP-AA | SAP-SA | SAP-NA |

Water absorption rate (g/g) | 188.3 | 101.3 | 226.55 |

Multiplication rate of deionised water (g/g) | 139 | 105.4 | 145.4 |

Multiplication rate of 0.9 % NaOH solution (g/g) | 40.49 | 50.8 | 65 |

Multiplication rate of saturated lime water (g/g) | 28 | 35 | 45 |

2.2. Orthogonal experimental design

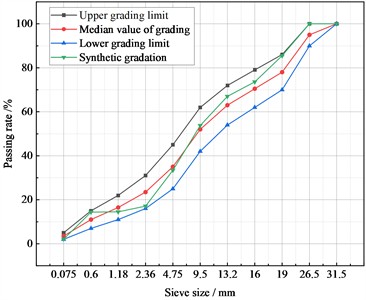

According to the relevant requirements of the specification “Highway pavement grass-roots construction technical rules” (JTGT F20-2015) and the results of aggregate sieve test, the skeleton dense structure is selected, the grading gravel is used CF-B-2S, and the synthetic grading of the mixture is shown in Fig. 1. Cement: Aggregate = 17:83, Cement: Fly ash = 1:3, 1:4, 1:5, using aeolian sand instead of 12 % of fine aggregate, SAP is the three types described in 2.1, and its dosage is 0.05 %, 0.1 %, 0.15 % of the mass of the cementitious material, and the additional water intake of SAP is 10 times, 20 times, and 30 times, and the dosage of cement-fly ash dosage, type of SAP, dosage of SAP, and the additional water intake of SAP are taken as the main factors in this orthogonal test. Water diversion as the four influencing factors of this orthogonal test, each factor is selected three levels, orthogonal test factor level table is shown in Table 4.

Table 4Four-factor three-level table

Factors | Cement-Fly ash | SAP type | SAP dosage / % | Additional water diversion/times |

1 | 1:3 | ionic | 0.05 | 10 |

2 | 1:4 | Non-ionic | 0.1 | 20 |

3 | 1:5 | Composite | 0.15 | 30 |

Fig. 1Mix synthetic grading curve

2.3. Sample preparation and test methods

In this paper, SAP dry mixing method is adopted, and the graded gravel (including aeolian sand) is mixed well with water, and the material is smothered with cling film covering for 6 h, and the SAP particles are mixed well with the cementitious materials before the test, and then added into the pre-wetted mixture and mixed well for the test. The maximum nominal particle size of the aggregate used in this paper is 26.5 mm, so the C method in the “Test Procedure for Stabilising Materials of Inorganic Binding Materials for Highway Engineering” (JTG 3441-2024) was chosen for the compaction test. The unconfined compressive strength test adopts the press static compression molding 150 mm×150 mm cylindrical specimen, dry shrinkage test molding 100 mm×100 mm×400 mm beam specimen, molding to be mold static 24 h±2 h after demolding, the use of plastic bag sealing moved into the standard perishable environment for standard perishable, to be tested when the age is reached.

3. Result and discussion

3.1. Dry shrinkage performance results and analysis

Table 5 shows the extreme difference analysis of 27 d average drying coefficient index of orthogonal test groups. From Table 5, it can be seen that the extreme difference of cement-fly ash (A) is the largest value of 61.85, the extreme difference of SAP dosage (C) is smaller of 40.06, the extreme difference of SAP type (B) is the second largest value of 29.51, and the extreme difference of additional water intake (D) is the smallest value of 23.31. It can be judged that the order of the primary and secondary factors is: cement-fly ash (A) > SAP type (B) > SAP dosage (C) >additional water intake (D), and the order of the primary and secondary factors is: cement-fly ash (A) > SAP type (B) > SAP dosage (C) > additional water intake (D).

Table 6 shows the analysis of variance of the mean drying coefficients for 27 d. Among them, when , , , is less than F0.1 (2,8) = 9.00, “-“ indicates no significant effect; when , , , is between F0.1 (2,8) = 9.00 and F0.05 (2,8) = 19.00, “*” indicates a significant effect; When , , , are between F0.05 (2,8) = 19.00 and F0.01 (2,8) = 99.00, “**” indicates a significant effect; when , , , and were greater than F0.01 (2,8) = 99.00, “***” was used to indicate that the effect was highly significant. Analysis of variance revealed that the effect of cement-fly ash (A) on the 27 d mean coefficient of drying was highly significant, and the effects of SAP type (B), SAP dosage (C) and additional water intake (D) on the 27 d mean coefficient of drying were more significant.

Table 5Orthogonal test group 27 d dry shrinkage coefficient index extreme difference analysis table

Serial number | A | B | C | D | Shrinkage factor / ×10-6 |

Cement-Fly ash | SAP type | SAP dosage / % | Additional water intake / times | ||

M1 | 1 | 1 | 1 | 1 | 178.60 |

M2 | 1 | 2 | 2 | 2 | 151.00 |

M3 | 1 | 3 | 3 | 3 | 185.50 |

M4 | 2 | 1 | 2 | 3 | 139.87 |

M5 | 2 | 2 | 3 | 1 | 123.99 |

M6 | 2 | 3 | 1 | 2 | 73.00 |

M7 | 3 | 1 | 3 | 2 | 140.00 |

M8 | 3 | 2 | 1 | 3 | 108.96 |

M9 | 3 | 3 | 2 | 1 | 80.20 |

K1 | 514.70 | 458.47 | 360.56 | 382.79 | T = 1181.122 |

K2 | 336.86 | 383.95 | 371.07 | 364.00 | |

K3 | 329.16 | 338.30 | 449.09 | 433.93 | |

Kavg1 | 171.57 | 152.82 | 120.19 | 127.60 | T/3 = 393.71 |

Kavg2 | 112.29 | 127.98 | 123.69 | 121.33 | |

Kavg3 | 109.72 | 112.77 | 149.70 | 144.64 | |

Rj | 61.85 | 40.06 | 29.51 | 23.31 | |

Order of priority A > B > C > D | |||||

Optimal combination A3B3C1D2 | |||||

Table 6Analysis of variance table of 27 d mean drying shrinkage coefficients

Source of variance | Deviation | Degrees of freedom | Mean square deviation | F-value | Critical value Fa | Significance |

A | 7377.72 | 2 | 3672.86 | 198.21 | F0.01= 99.00 | *** |

B | 2453.11 | 2 | 1226.55 | 66.19 | F0.05= 19.00 | ** |

C | 1559.46 | 2 | 779.73 | 42.08 | F0.1= 9.00 | ** |

D | 873.17 | 2 | 436.59 | 23.56 | ||

Inaccuracies | 148.24 | 8 | 18.53 | |||

Sum | 12279.70 | 16 |

3.2. Unconfined compressive strength results and analysis

Table 7 shows the extreme difference analysis table of 7 d unconfined compressive strength index of orthogonal test group. It can be seen from Table 7 that the extreme difference value of SAP type (B) is the largest 2.12, the extreme difference value of SAP dosage (C) is the smaller 1.40, the extreme difference value of additional water intake (D) is the second largest 0.55, and the extreme difference value of cement-fly ash (A) is the smallest 0.23, which indicates that SAP has a significant effect on the strength of semi-rigid base. It shows that SAP has a significant effect on the strength of semi-rigid base, and SAP type has the greatest effect on the unconfined compressive strength of cement-fly ash-stabilised sandy semi-rigid base. From the size of the extreme difference value of each factor, the order of the primary and secondary factors can be judged as follows: SAP type (B) > SAP dosage (C) > additional water intake (D) > cement-fly ash (A).

Table 8 shows the analysis of variance of 7 d unconfined compressive strength. Among them, when , , , is less than F0.1 (2,14) = 2.73, “–” indicates no significance; when , , , is between F0.1 (2,14) = 2.73 and F0.05 (2, 14) = 3.74, “*” indicates a significant effect; when , , , are between F0.05 (2,14) = 3.74 and F0.01 = 6.51, “**” indicates a more significant effect; when , , , is greater than F0.01 (2,14) = 6.51, “***” is used to indicate that the effect is highly significant. It was found that the effects of SAP type (B) and SAP dosage (C) on 7 d unconfined compressive strength were very significant.

Table 7Extreme difference analysis of 7 d unconfined compressive strength index of orthogonal test group

Serial number | A | B | C | D | 7 d unconfined compressive strength / MPa |

Cement-Fly ash | SAP type | SAP dosage / % | Additional water intake/times | ||

M1 | 1 | 1 | 1 | 1 | 2.58 |

M2 | 1 | 2 | 2 | 2 | 5.49 |

M3 | 1 | 3 | 3 | 3 | 4.70 |

M4 | 2 | 1 | 2 | 3 | 2.64 |

M5 | 2 | 2 | 3 | 1 | 5.91 |

M6 | 2 | 3 | 1 | 2 | 3.67 |

M7 | 3 | 1 | 3 | 2 | 4.13 |

M8 | 3 | 2 | 1 | 3 | 4.30 |

M9 | 3 | 3 | 2 | 1 | 3.65 |

K1 | 12.77 | 9.35 | 10.55 | 12.14 | T = 37.07 |

K2 | 12.22 | 15.70 | 11.78 | 13.29 | |

K3 | 12.08 | 12.02 | 14.74 | 11.64 | |

Kavg1 | 4.26 | 3.12 | 3.51 | 4.05 | T/3 = 12.56 |

Kavg2 | 4.07 | 5.23 | 3.93 | 4.43 | |

Kavg3 | 4.03 | 4.01 | 4.91 | 3.88 | |

Rj | 0.23 | 2.12 | 1.40 | 0.55 | |

Order of priority B > C > D > A | |||||

Optimal combination A1B2C3D2 | |||||

Table 8Analysis of variance table for 7 d unconfined compressive strength indicator

Source of variance | Deviation | Degrees of freedom | Mean square deviation | F-value | Critical value Fa | Significance |

B | 6.78 | 2 | 3.39 | 67.80 | F0.1= 2.73 | *** |

C | 3.09 | 2 | 1.55 | 30.90 | F0.05= 3.74 | *** |

Inaccuracies | 0.57 | 12 | 0.05 | F0.01= 6.51 | ||

Sum | 10.44 | 16 |

4. Conclusions

1) The effect of SAP type and additional water intake on the 27 d average dry shrinkage coefficient is more significant. Considering all the factors, it is recommended that the proportion composition of the semi-rigid base layer based on the internal curing technology is 1:4 for cement-fly ash, 17:83 for cementitious material: aggregate, 12 % fine aggregate replaced by aeolian sand, the SAP type is the composite SAP-NA, the dosage of SAP is 0.05 %, and the additional water intake is 20 times.

2) Extreme difference analysis of the results of 7 d unconfined compressive strength test was carried out, and the order of the primary and secondary factors affecting the test results was as follows: SAP type > SAP dosage > additional water intake > proportion of cementitious materials, and the optimal combination of which was A1B2C3D2; analysis of variance showed that the SAP type and SAP dosage had a very significant effect on the 7d unconfined compressive strength.

References

-

Z. Zheng, S. Du, H. Taubenböck, and X. Zhang, “Remote sensing techniques in the investigation of aeolian sand dunes: A review of recent advances,” Remote Sensing of Environment, Vol. 271, p. 112913, Mar. 2022, https://doi.org/10.1016/j.rse.2022.112913

-

H. Zhang, A. Luo, and L. Sun, “Mixture composition design of magnesium oxychloride cement-stabilized crushed stone materials applied as a pavement base,” Scientific Reports, Vol. 14, No. 1, p. 11656, May 2024, https://doi.org/10.1038/s41598-024-62602-1

-

J. Chen et al., “Investigation of transverse crack spacing in an asphalt pavement with a semi-rigid base,” Scientific Reports, Vol. 12, No. 1, p. 18079, Oct. 2022, https://doi.org/10.1038/s41598-022-23122-y

-

B. Jiang, L. Xu, Z. Cao, Y. Yang, Z. Sun, and F. Xiao, “Interlayer distress characteristics and evaluations of semi-rigid base asphalt pavements: A review,” Construction and Building Materials, Vol. 431, p. 136441, Jun. 2024, https://doi.org/10.1016/j.conbuildmat.2024.136441

-

Z. He et al., “Cement-based materials modified with superabsorbent polymers: A review,” Construction and Building Materials, Vol. 225, pp. 569–590, Nov. 2019, https://doi.org/10.1016/j.conbuildmat.2019.07.139

-

L. Li, H. Chai, Y. Hu, R. He, and Z. Wang, “Feasibility study on superabsorbent polymer (SAP) as internal curing agent for cement-based grouting material,” Construction and Building Materials, Vol. 411, p. 134286, Jan. 2024, https://doi.org/10.1016/j.conbuildmat.2023.134286

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.