Abstract

This research utilized a multilayer perceptron model based on an artificial neural network (ANN) to improve concrete blocks by partially replacing stone dust and cement with coconut shell and coconut shell ash. From 35 experimental data points, 68.6 % were used for training and 31.4 % for testing. Chemical analyses showed that coconut shell ash, rich in silicon and other oxides, enhanced pozzolanic reactions as a cement substitute. Results indicated that higher proportions of coconut shell ash and shells reduced density, making the mixture lighter but potentially affecting structural integrity. However, increased replacement levels improved workability, shown by higher slump values. The curing period significantly impacted strength, with longer times leading to increased strength due to continued hydration. An optimal compressive strength of 14.17 N/mm2 was achieved with a 5 % replacement after 70 days. The ANN model demonstrated a sum square error of 0.198 and a high correlation coefficient of 0.983 when predicting strength. Optimal conditions for achieving a compressive strength of 33.4 N/mm2 were identified, underscoring the cost-effectiveness of using coconut byproducts instead of traditional materials.

Highlights

- The study used a multilayer perceptron ANN to improve concrete blocks by replacing stone dust and cement with coconut shell and coconut shell ash, highlighting enhanced pozzolanic reactions and workability gains.

- Data: 35 experimental points with 68.6% for training and 31.4% for testing; ANN achieved a sum of squared errors of 0.198 and a correlation coefficient of 0.983 for strength predictions.

- Material effects: higher coconut shell ash and shell content reduced density (lighter mix) but could influence structural integrity if overused; curing time reinforced strength through ongoing hydration.

- Performance milestones: optimal 14.17 N/mm² compressive strength at 5% replacement after 70 days; predicted 33.4 N/mm² strength under identified optimal conditions, underscoring coconut byproducts as cost-effective substitutes.

1. Introduction

Building materials reliant on cement paste have consistently held their top position as the most commonly utilized materials in the construction sector [1]. The manufacturing process of cement typically results in the release of carbon dioxide into the atmosphere, contributing to approximately 6-7 % of the overall carbon dioxide emissions, which leads to environmental harm, as emphasized by authors in [2]. Consequently, reducing the volume of cement production can be advantageous in mitigating its adverse effects on society [3-5].

However, challenges such as cost, environmental sustainability, durability, and efficiency have emerged in the construction sector due to the monopolization or high demand for these constituents [6]. In recent times, many materials, including blocks, concrete, and reinforcement, have seen price hikes exceeding 100 % in Nigeria and various other African nations [7]. This surge in material costs has significantly impacted properties for block molding, with issues arising from poor mix proportions, inadequate water content, improper curing times, substandard molds, incorrect transloading techniques, and other factors [8]. Building blocks, crucial in construction, are currently facing a decline in quality in the labor market.

Concrete continues to be the predominant material in commercial construction, especially when prioritizing strength. Its longevity and eco-friendliness have maintained its supremacy over other materials [9]. Structural engineers are directing their attention towards identifying alternative construction materials, especially in the case of blocks, as they are seen as essential yet limited in their applicability in building structures. On the other hand, the significance of bio-waste has risen as a substantial economic and eco-friendly substitute in construction endeavours [10]. The advantages of utilizing concrete blocks include cost-effective upkeep, enhanced fire resistance, and structural load-bearing capacity as noted by authors in [11, 12]. According authors in [13], concrete blocks present benefits compared to sandcrete blocks such as improved strength, durability, and eco-friendliness

Multiple research studies have explored the use of various agricultural byproducts such as rice husks, coconut shells, and palm fronds in construction using different techniques [14]. Among these agricultural residues, coconut shells have shown satisfactory strength and durability, meeting the criteria outlined in the [15] standard. By integrating alternative materials like coconut shells and coconut shell ash, the properties of concrete blocks can be enhanced, creating a building material that is both environmentally friendly and cost-effective compared to sandcrete blocks [16]. However, the weight of concrete blocks poses a challenge in tall structures, leading to the exploration of lightweight concrete block as a viable alternative. Coconut shells are identified as a cost-effective and readily available choice to produce a lightweight concrete block in tropical regions worldwide [17, 18].

Using coconut shells and coconut shell ash as sustainable substitutes for aggregate and cement in concrete production has been extensively studied. Authors in [19] studied the mechanical properties, environmental impact, and economic viability of coconut shell ash as a sustainable alternative in concrete blends, aiming to reduce reliance on traditional materials. Their analysis of concrete blocks incorporating agricultural waste offers insights for eco-friendly construction techniques [20]. This study uniquely focuses on the impact of coconut shells as an aggregate replacement on concrete's compressive strength, addressing a gap in previous research.

Authors in [21] researched sustainable concrete block production using coconut shells as an alternative aggregate, evaluating the feasibility, mechanical strength, moisture resistance, and cost-effectiveness of these blocks. Similarly, authors in [22] studied coconut shell ash as a partial cement substitute in concrete blocks, assessing its mechanical properties, workability, and sustainability, highlighting its potential as an environmentally friendly alternative. Authors in [23] examined how partially replacing stone dust with coconut shells enhances aggregate properties in concrete blocks, focusing on structural performance and environmental benefits. Authors in [24] investigated the optimization of concrete block production by partially substituting cement with coconut shell ash, analyzing its effects on compressive strength, durability, and environmental impact. Similarly, authors in [25] explored the effects of partially replacing both stone dust and cement with coconut shells, assessing their influence on strength, durability, and sustainability in block manufacturing.

The studies emphasize the advantages and challenges of using coconut shells and ash in concrete blocks, stressing the importance of optimizing material proportions for cost, strength, and sustainability, particularly in achieving desired compressive strength [26, 27, 28]. To address the difficulties of experimental value determination, researchers have developed various predictive techniques. Approaches like Scheffé’s method have demonstrated that classical models become overly complex when multiple components are involved, leading to the evolution of artificial neural network (ANN) modeling techniques [31, 32, 33]. In their comprehensive review, [33] explored the diverse applications of artificial neural networks (ANNs) in materials engineering, focusing on their ability to optimize material properties, predict behaviors, and improve manufacturing processes. The review also addresses the advantages and challenges of using ANNs in this field. Similarly, authors in [34] investigated the applicability of neural networks for predictive modeling of material properties in the construction sector, specifically training the networks to forecast critical characteristics like compressive strength, durability, and thermal conductivity. They outlined the methodology, data sources, and results from using neural networks for this predictive modeling. Additionally, [35] explore how NN techniques can facilitate feature selection and modeling in materials engineering. By examining how NN can automatically identify relevant features within complex datasets, this study highlights the improved predictive accuracy and efficiency these methodologies provide for material analysis and design. The review also discusses the opportunities and challenges of integrating neural networks in materials engineering research.

Artificial neural network modeling techniques significantly outperform traditional statistical methods like Scheffé's and Osadebe’s models due to their ability to manage larger numbers of components effectively [36]. Unlike the complexities encountered with process variables and orthogonal block design inverse terms in classical models, ANNs offer a more adaptable and dynamic approach for modeling complex systems. The authors in [36] emphasize the advantages of Artificial Neural Networks (ANNs) over traditional modeling approaches like Scheffé’s due to ANNs' ability to capture complex, non-linear data relationships. This flexibility allows ANNs to effectively manage large, high-dimensional datasets, making them well-suited for modeling the mechanical properties of concrete mixtures with coconut shells and ash. Building on this, [37] highlights how ANNs, particularly Extreme Learning Machines, can identify subtle interactions among data components without needing extensive parameter tuning. Their research shows that ANNs can optimize concrete block mixtures for sustainability and mechanical performance, specifically compressive strength.

The authors in [38] focuses on material optimization in designing and comparing an advanced fuzzy-based controllers (FTID vs. PID) for a process control system, emphasizing improved accuracy, robustness, and fault-tolerance. They enhances control system performance using fuzzy logic and evolutionary algorithms; they serve different purposes and are tailored to their respective fields compared to the proposed algorithm in the present work which uses an artificial neural network (ANN) to predict and optimize the strength of concrete mixes incorporating coconut shell ash and shells, demonstrating high accuracy and cost-effectiveness in improving material properties. The ANN here can be extended to other material properties or different materials, making it versatile for various civil engineering applications unlike the control system’s fuzzy-based design in [38] which more confined to process control contexts and does not directly influence material science or sustainability.

Authors in [39-42] utilize machine learning and data-driven methods to address civil engineering challenges. Specifically, authors in [39] employs artificial neural networks (ANN) to forecast concrete strength; authors in [40] uses support vector machines (SVM) for modeling material properties; authors in [41] applies fuzzy logic systems to assess construction safety; and authors in [42] leverages genetic algorithms (GA) for structural optimization. Their focus is on enhancing prediction accuracy and design efficiency. However, a limitation for proposed work is that these techniques used by authors [39-40] are primarily geared toward predictive modeling and system optimization, offering limited direct benefit to society or the environment compared to present study emphasis on sustainable construction materials integrated with machine learning.

The main distinction between present study and authors in [39] lies in their scope and objectives. While the present study aims to promote sustainability in civil engineering by developing eco-friendly materials – particularly coconut waste-based concrete – using machine learning, authors in [39] work centers on predicting concrete strength to improve material performance without explicitly addressing environmental or societal impacts. Thus, present work fosters broad societal benefits through sustainability, whereas authors in [39] research is more technical and specialized within material science.

Additionally, in [39], authors develop and compare advanced fuzzy controllers for process systems focusing on improving control performance, robustness, and fault tolerance. While valuable, these improvements are more narrowly applicable, with limited broader societal implications. Conversely, the ANN-based optimization of concrete in the present work offers wider societal and environmental advantages by advancing eco-friendly, cost-effective, and stronger construction materials. Similarly, the current approach’s focus on sustainable material development surpasses the control-centered methods in [40], [41], and [42], even the author [42] that used ANN all primarily targeted industrial system optimization. Generally, the proposed ANN method delivers a broader societal impact by promoting environmental sustainability and resource efficiency.

Authors [43-48] uses primarily technical control advancements and concentrated on developing sophisticated optimization algorithms and fuzzy logic techniques to enhance control systems. They applied various metaheuristic, control and optimization methods to achieve notable improvements in system resilience, fault management, and parameter adaptability, providing valuable tools for complex automation tasks: authors in [43] uses metaheuristic algorithms like flower pollination and harmony search for fuzzy controller tuning; authors in [44] employs fuzzy-based metaheuristics with interval type-2 fuzzy logic; authors in [45] utilizes fuzzy logic and metaheuristic algorithms (flower pollination, genetic algorithms) for fault-tolerant control; authors in [46] designs fuzzy fractional-order controllers optimized with metaheuristics; authors in [47] applies cuckoo search to optimize interval type-2 fuzzy controllers; and author in [48] uses Lévy flights within cuckoo search for parameter optimization. These approaches aim to improve the robustness, fault tolerance, and accuracy of control systems in engineering applications. However, their drawback in relation to the present study which are highly focused on intricate control system development, offering limited societal or environmental impact, unlike the present work which emphasis on sustainable construction materials and environmentally friendly civil engineering solutions. Compared to the primarily technical control advancements of authors [43-48], the proposed approach has a broader positive impact on environmental and societal sustainability.

Authors [49-56] employ sophisticated control and optimization techniques such as fuzzy logic, metaheuristic algorithms (including flower pollination, harmony search, cuckoo search, and genetic algorithms), and Takagi–Sugeno fuzzy models to improve the stability, robustness, and fault tolerance of complex systems. Each uses specific methods – fuzzy logic for dynamic parameter adjustment [49, 53], metaheuristics for controller optimization [50, 54, 55], and fuzzy models for ensuring stability [56] – aiming to enhance control accuracy and manage uncertainties in industrial, structural, and process applications. However, their approaches remain narrowly focused on technical system improvements, with limited consideration for societal or environmental impacts. In contrast, the proposed work centers on sustainable civil engineering by applying machine learning to environmentally friendly concrete, offering broader societal and ecological benefits beyond the specialized control advancements of authors [49-56].

Recent studies highlight the increasing focus on utilizing agricultural by-products, like coconut shell ash, to advance sustainable construction practices. Researches in [38-41], [43-49], and [56] have extensively examined metaheuristic algorithms and fuzzy control techniques to improve the reliability and optimization of these environmentally friendly materials for applications such as level control, fault-tolerant systems, and nonlinear system management. Other works [42, 51-53] concentrate on incorporating agricultural wastes like rice husk ash, ceramic waste, and palm oil fuel ash into green concrete and geopolymer composites, showcasing their potential as resource-efficient and eco-conscious alternatives.

These efforts demonstrate notable benefits, including waste valorization, decreased reliance on traditional cement, and reduced environmental impacts. Nevertheless, challenges persist, such as variability in waste material quality, potential reductions in durability stemming from increased porosity and water absorption, and the need for optimized mixing and curing strategies. The limitations of these materials – particularly their potential vulnerability to environmental stressors – are now explicitly addressed in this section, underscoring the necessity for continued research to improve processing methods or optimization modeling techniques and ensure the long-term sustainability and structural integrity of eco-friendly construction materials.

The current research utilizes ANNs modeling technique to model and predict the compressive strength of concrete blocks using coconut shell and ash as substitutes for cement and stone dust. It aims to develop a multilayer perceptron via a feed-forward approach, systematically exploring various combinations of cement, water, aggregate proportions, and curing conditions to find the optimal mix that balances cost-effectiveness with strength and durability.

2. Materials and methods

2.1. Materials

The components utilized in this investigation comprise coconut shell ash, ordinary Portland cement (OPC), water, fine aggregate (stone dust one), and crushed granite chippings (stone dust two). Each of these components will be elaborated upon in the following sections.

2.1.1. Ordinary portland cement

The cement utilized in this research is the BUA brand of Ordinary Portland Cement, 50 kg with a 30 % normal consistency, conforming to (CEM II) standards as prescribed by the NIS 444-1 specification (NIS, 2000) [57]. These were bought from our local market.

2.1.2. Nanostructured coconut shell ash

Coconut shells were harvested and collected from the Enugu metropolitan area, where they were processed by removing the fibrous outer parts and sun-drying for three days to eliminate moisture. The shells were then manually broken into smaller pieces using a hammer before being burned in a furnace at temperatures between 500 °C and 850 °C for two hours [58], complying with controlled carbonization standards. Electric kilns were used for this incineration process, after which the shells were cooled for three hours. The resulting material was sieved to obtain fine coconut shell ash, which was subsequently analyzed for its composition.

2.1.3. Water

Water plays a crucial role in concrete mixing, as insufficient or excessive amounts can greatly affect the mixture and the overall strength of the concrete. Therefore, a thorough evaluation of the water-cement ratio was carried out for each mix. Furthermore, recognizing the influence of water quality on concrete strength, pure potable water free of undesirable chemicals, meeting the specifications of [59] for concrete mixtures, was employed in this study.

2.1.4. Aggregates

Two categories of aggregates were employed in the research project. They include:

1) Fine aggregate: Clean quarry dust from stone and gravel vendors in Abakaliki, Ebonyi state, meeting BS EN 12,620 standards and referred to as Stone Dust One, was utilized. This fine aggregate was sieved through a 2.36 mm mesh size.

2) Coarse aggregate: Well-graded coarse aggregate, meeting [60] criteria and comprising crushed stone with a 10 mm diameter, was sourced from stone and gravel suppliers in Abakaliki, Ebonyi state, designated as Stone Dust Two. Both types of aggregates were air-dried, weighed, and proportioned before the experiments. Assessments including specific gravity, bulk density, and dry density were performed on the aggregates. Sieve analysis tests were also conducted to determine particle size distribution, which was graphically represented using a semi-logarithmic scale.

2.1.5. Selection of material proportions

These selected proportions ensure a comprehensive evaluation of mechanical properties that facilitates identifying an optimal mix. The statistical analysis conducted through repeated trials emphasizes the reliability of results, supporting practical applications in sustainable concrete production. Table 1 encapsulates the chosen proportions for replacement of cement and stone dust with their curing ages.

This selection was based on the following justifications:

Coconut Shells and Ash as Alternative Materials: Previous studies have shown that coconut shells and their ash have pozzolanic properties, which can enhance the performance of concrete by increasing its strength and durability [61]. The varying replacement proportions were selected to find the optimal mix that maximizes these advantages while examining the acceptable thresholds for compressive strength.

Range of Replacement Levels The chosen proportions systematically range from complete replacement (100 %) to a minimum where only a limited amount of coconut materials is used (75 % cement replacement), facilitating an evaluation of performance across various mixes. This method enables the identification of not only the optimal mix but also the critical thresholds beyond which mechanical properties may decline, as indicated by the results of [62].

Experimental Design for Reliability and Validity: Each experiment was conducted in triplicate to ensure reliable results. These repetitions account for variability in mixing and curing processes, allowing for more robust statistical analysis. A randomized complete block design (RCBD) was employed to enhance the validity of the experiment by controlling potential confounding factors during the preparation of the concrete blocks.

Effects of Curing Age: Curing periods of 7, 14, 21, 28, 42, 56, and 70 days were chosen based on standard concrete testing practices. These durations are typically utilized to evaluate the development of strength in concrete [63], providing a comprehensive understanding of how mechanical properties evolve over time as coconut materials interact with the cement matrix.

Statistical Analysis Standards: Following the guidelines outlined in [64] and [65], the results from each trial were statistically analyzed, particularly focusing on the standard deviation and average compressive strength at each replacement level. By examining variations across the three repetitions, the analysis confidently determined the impact of coconut replacements on concrete performance.

Table 1The proportion of materials used in the concrete mixes

Cement replacement levels (%) | Coconut shell ash replacement levels (%) | Curing ages (days) |

100 | 0 | 7 |

95 | 5 | 14 |

90 | 10 | 21 |

85 | 15 | 28 |

80 | 20 | 42 |

75 | 25 | 70 |

2.2. Methods

2.2.1. Procedure of the research with material quantities

In this study, the materials were thoroughly examined for physical properties such as specific gravity, particle size distribution, and bulk density. The aggregates were mixed according to a Block Mix Design of 1:6, combining 1 part cement with 6 parts fine (dust) and coarse aggregates. Chemical properties of coconut shell ash powder (CSAP) and cement were analyzed using X-ray diffraction (XRD) to identify their mineralogical characteristics and hydration products. Coarse and fine aggregates were proportioned at 70 % stone dust and 30 % coarse aggregate, followed by mass batching in a dry state.

After mixing, concrete was poured into molds, and a slump test was performed on the fresh mix. A Vicat apparatus was used to measure the initial and final setting times. Samples were cured at room temperature with regular water application until compressive strength testing. After 70 days of curing, the hardened concrete blocks were assessed for density, water absorption, and compressive strength using a Universal Compression Machine [66]. A total of 756 cubes were produced from 252 mixes, yielding 42 data points, with 39 used for model construction and 3 reserved for performance assessment, selected via an artificial neural network modeling technique.

2.2.2. Artificial neural network applications and other modeling techniques

Using Artificial Neural Networks (ANNs) for modeling, optimizing, and performing sensitivity analysis on concrete blocks presents several advantages over traditional methods like Scheffé’s approach [67]. ANNs excel in managing complex, nonlinear relationships between input and output variables, capturing intricate patterns in concrete block data that traditional statistical methods struggle with. They can also handle large and diverse datasets, making them suitable for analyzing intricate systems.

Another key benefit is ANNs’ adaptability; they improve their predictive accuracy over time as they learn from data, allowing them to adjust to changing conditions without the need for manual updates, unlike the more rigid Scheffé method. ANNs effectively model nonlinear relationships common in materials engineering, capturing interactions that linear regression models may overlook [68]. Additionally, ANNs feature automatic data extraction capabilities, identifying relevant factors influencing concrete block performance without extensive manual input, thus streamlining the optimization process. Generally, employing ANNs enhances flexibility, scalability, and efficiency in materials engineering and construction research, providing valuable insights for innovative solutions in the industry.

3. Results and discussion

3.1. Chemical properties of cement and aggregates materials in the concrete mix

X-ray fluorescence tests were conducted as presented in Table 2 to analyze the chemical composition of cement, stone dust, coconut shells, and coconut shell ash, following ASTM C 618 (2008) standards [69] and [70]. The results showed that Portland cement contains 18.22 % silicon oxide, 2.72 % iron oxide, 3.31 % sulfur oxide, 60.14 % calcium oxide, 5.11 % aluminum oxide, and 7.23 % titanium oxide, along with trace amounts of magnesium oxide, potassium oxide, sodium chloride, and phosphorus oxide.

Stone dust had high levels of silicon oxide (53.058 %), iron oxide (12.176 %), and sulfur oxide (11.134 %), but lower levels of calcium oxide (5.302 %) and aluminum oxide (8.920 %). Coconut shells predominantly featured calcium oxide (62.538 %), silicon oxide (12.024 %), iron oxide (5.595 %), and sulfur oxide (4.678 %), with minimal magnesium oxide and titanium oxide content.

Incineration of coconut shells into ash resulted in increased percentages of silicon oxide, iron oxide, sulfur oxide, magnesium oxide, potassium oxide, titanium oxide, chlorine, and phosphorus oxide, while aluminum oxide and calcium oxide levels decreased. Other chemical compounds present in negligible amounts were considered insignificant for material performance.

The data reveals that stone dust contains high levels of silicon oxide, iron oxide, sulfur oxide, calcium oxide, potassium oxide, and aluminum oxide, while coconut shells are rich in calcium oxide, silicon oxide, iron oxide, potassium oxide, and aluminum oxide. Stone dust’s significant silicon oxide content grants it pozzolanic properties, enhancing cement performance by reacting with calcium hydroxide to form calcium silicate hydrate, thereby improving concrete strength and durability. Coconut shells, on the other hand, also contribute to pozzolanic properties when converted to ash, especially with increased reactivity observed post-incineration.

The chemical composition results suggest that both stone dust and coconut shell ash show promise as supplementary materials to enhance the pozzolanic properties of cement. Specifically, using coconut shell ash as a cement substitute could significantly improve pozzolanic reactions compared to traditional Portland cement and stone dust. The increased levels of silicon oxide and other oxides in coconut shell ash after incineration can lead to additional calcium silicate hydrate formation, enhancing concrete's strength, durability, and chemical resistance.

Furthermore, the higher concentrations of magnesium oxide, potassium oxide, titanium oxide, chlorine, and phosphorus oxide in coconut shell ash may influence the mix’s chemical composition, affecting properties like setting time, workability, and durability. Adjustments in mix design may be necessary due to the lower levels of aluminum oxide and calcium oxide in coconut shell ash compared to traditional cement. Thus, utilizing coconut shell ash as a cement alternative could offer benefits for pozzolanic reactions in concrete, resulting in stronger structures, but further testing and evaluation are essential to optimize the mix design and ensure desired performance characteristics are achieved.

Table 2Chemical composition of cement, stone dust, coconut shell, coconut shell-ash

Chemical compound | Materials composition (%) | |||

Cement | Stone dust | Coconut shell | Coconut shell-ash | |

Silicon Oxide (SiO2) | 18.22 | 53.058 | 12.024 | 14.804 |

Iron Oxide (Fe2O3) | 2.72 | 12.176 | 5.595 | 11.601 |

Sulfur Oxide (SO3) | 3.31 | 11.134 | 4.678 | 5.092 |

Calcium Oxide (CaO) | 60.14 | 5.302 | 62.538 | 9.299 |

Magnesium Oxide (MgO) | 1.25 | 0.000 | 0.000 | 0.491 |

Potassium Oxide (K2O) | 0.08 | 5.574 | 3.152 | 33.296 |

Aluminum Oxide (Al2O3) | 5.11 | 8.920 | 7.010 | 5.609 |

Titanium Oxide (TiO2) | 7.23 | 1.934 | 0.957 | 1.198 |

Sodium Chlorine (NaCl) | 0 | 0.804 | 2.424 | 7.014 |

Phosphorus Oxide (P2O5) | 0.04 | 0.000 | 0.404 | 6.980 |

3.2. Physical properties of the cement and aggregates materials in the fresh concrete blocks

The physical characteristics of fresh mixtures for cement-granite concrete blocks and coconut shell-ash concrete blocks were analyzed with varying replacement ratios and presented in Table 3. The study found that, as cement and stone dust were partially replaced (from 100 % to 75 % in 5 % increments) with 0 % to 25 % coconut shell ash and shells, the density of the mixtures consistently decreased from 2,276.97 kg/m3 to 2,017.53 kg/m3. Simultaneously, the slump increased from 12 mm to 15.2 mm, and water absorption rose from 3.35 % to 5.48 %.

These findings indicate that the inclusion of coconut shell ash and shells results in lighter mixtures with improved workability due to higher slump values, facilitating easier placement and shaping during construction. However, the increased water absorption suggests higher porosity, which may lead to reduced durability and greater susceptibility to cracking, potentially increasing maintenance needs for concrete structures. The results emphasize the impact of these materials on the density and overall performance of concrete.

Table 3Properties of the fresh mix for cement blocks

Cement content (%) | Stone dust content (%) | Coconut shells content (%) | Coconut shells ash content (%) | Density (kg/m3) | Slump (mm) | Water absorption (%) |

100 | 100 | 0 | 0 | 2,276.97 | 12 | 3.35 |

95 | 95 | 5 | 5 | 2,138.49 | 12.2 | 4.31 |

90 | 90 | 10 | 10 | 2,118.46 | 14.2 | 4.82 |

85 | 85 | 15 | 15 | 2,070.98 | 14.8 | 5.00 |

80 | 80 | 20 | 20 | 2,042.16 | 15.1 | 5.26 |

75 | 75 | 25 | 25 | 2,017.53 | 15.2 | 5.48 |

The study analyzed the physical characteristics of fresh mixtures for cement-granite concrete blocks and coconut shell-ash concrete blocks at varying replacement ratios. It found that partially replacing cement and stone dust (from 100 % to 75 % in 5 % increments) with 0 % to 25 % coconut shell ash and shells decreased the mixture’s density from 2,276.97 kg/m3 to 2,017.53 kg/m3. Concurrently, the slump increased from 12 mm to 15.2 mm, and water absorption rose from 3.35 % to 5.48 %.

These results indicate that incorporating coconut shell ash and shells leads to lighter mixtures with improved workability. However, the higher water absorption suggests increased porosity, which could reduce durability and increase the risk of cracking, potentially leading to higher maintenance requirements for concrete structures. In summary, the findings highlight the impact of these materials on the density and performance of concrete.

The replacement levels of 0 %, 5 %, 10 %, 15 %, 20 %, and 25 % for coconut shell ash and shells were deliberately chosen to enable a comprehensive and structured assessment of their influence on concrete block properties. Beginning at 0 %, the incremental increases of 5 % allow for detailed monitoring of how these materials affect strength, density, and workability, aiding in identifying an optimal proportion. Since higher replacement levels tend to decrease density and potentially weaken structural integrity, the maximum limit of 25 % strikes a balance between leveraging the environmental and economic benefits of coconut waste and preserving acceptable concrete block quality, as supported by existing research. This range facilitates straightforward laboratory testing and aligns with practical construction contexts. It also provides a diverse dataset for the neural network to effectively learn the complex relationships between material ratios and concrete performance, ensuring accurate modeling and optimization. Generally, these carefully selected levels harmonize sustainability objectives, structural performance, and experimental practicality, making them relevant for both practical applications and scientific investigations. This systematic approach not only supports detailed analysis but also promotes eco-friendly material development while maintaining essential mechanical properties.

3.3. Mechanical properties of the hardened concrete blocks at different curing ages

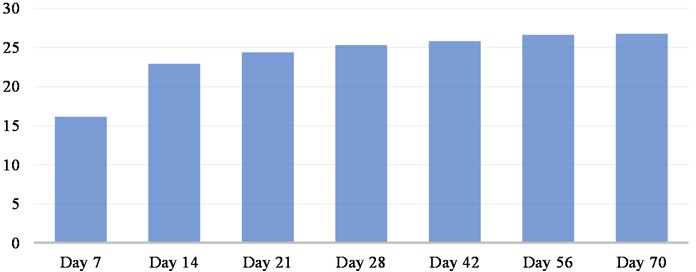

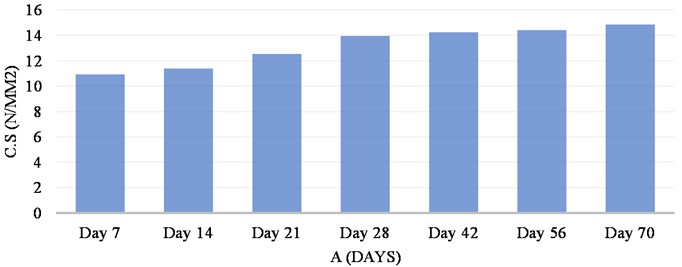

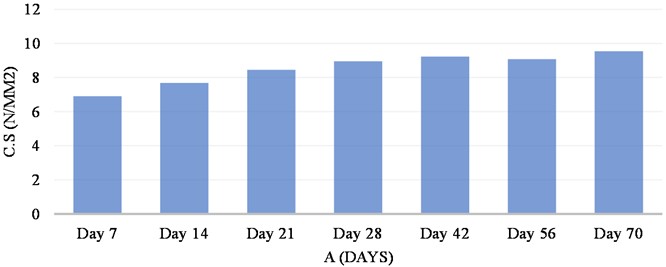

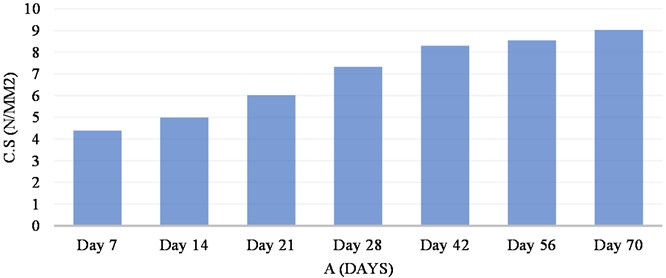

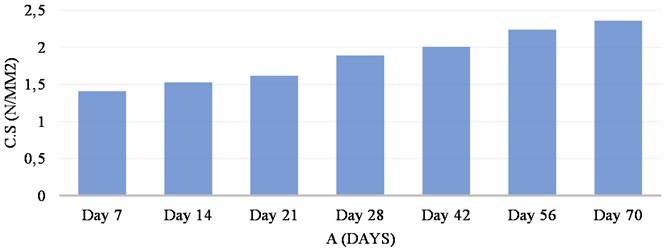

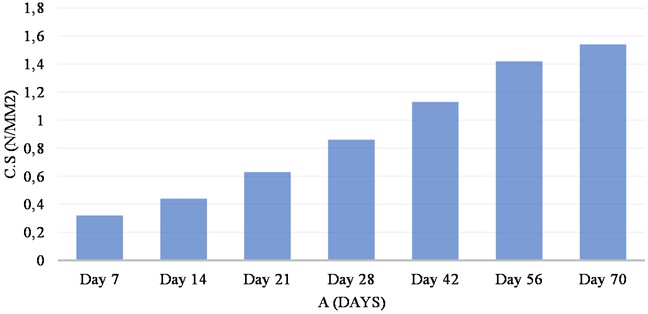

Figs. 1 to 6 display the compressive strength values for various cement and stone dust mixes partially replaced with coconut shells and coconut shell ash during curing periods of 7 to 70 days. The results showed that compressive strength significantly increased with longer curing times, ranging from 16.14 N/mm2 at 7 days to 26.77 N/mm2 at 70 days.

Fig. 1Bar chart for compressive strength and curing age for 0 % replacement

Fig. 2Bar chart for compressive strength and curing age for 5 % replacement

Fig. 3Bar chart for compressive strength and curing age for 10 % replacement

Fig. 4Bar chart for compressive strength and curing age for 15 % replacement

Fig. 5Bar chart for compressive strength and curing age for 20 % replacement

Fig. 6Bar chart for compressive strength and curing age for 25 % replacement

The study examined replacement percentages of 0 %, 5 %, 10 %, 15 %, 20 %, and 25 %, revealing varying strength outcomes. For example, with 0 % replacement, strength improved from 16.14 N/mm2 on day 7 to 26.77 N/mm2 by day 70. At 5% replacement, strengths ranged from 10.93 N/mm2 to 14.87 N/mm2; at 10 %, from 6.91 N/mm2 to 9.55 N/mm2; at 15 %, from 4.39 N/mm2 to 9.02 N/mm2; at 20 %, from 1.41 N/mm2 to 2.36 N/mm2; and at 25 %, from 0.32 N/mm2 to 1.54 N/mm2. Higher replacement percentages correlated with reduced strength, with the 25 % replacement resulting in the lowest compressive performance.

The test results reveal a clear relationship between partial replacement of cement and stone dust with coconut shells and coconut shell ash, curing duration, and compressive strength of concrete. At 0 % replacement, compressive strength reached a maximum of 26.77 N/mm2 after 70 days. As replacement percentages increased (5 %, 10 %, 15 %, 20 %, and 25 %), compressive strength decreased, with the lowest strength at 25 % replacement. The water-cement ratio rose from 55 % to 61 % due to increased water absorption from the replacements, indicating reduced mixture density. The study found that lower replacement levels can enhance compressive strength, while higher levels adversely affect concrete performance. Longer curing durations (7 to 70 days) were crucial for strength development, with an optimal compressive strength of 14.17 N/mm2 achieved at 5 % replacement after 70 days. The research underscores the importance of balancing mix proportions, replacement levels, and curing durations to achieve desired strength and durability in concrete. Monitoring concrete samples during curing is essential for ensuring quality and performance in practice.

3.4. Relationships between water-cement ratio (w/c), replacement percentages, and compressive strength

The relationship between the water-cement ratio (w/c) and compressive strength is fundamental; generally, a lower w/c ratio results in higher strength because it reduces porosity, leading to a denser and more durable concrete. In the context of the data, higher cement content – such as 61 % compared to 55 % – can also enhance strength potential, assuming other factors remain constant, since more binder promotes better cohesion and strength development.

Regarding replacement percentages of coconut shell ash and shells, increasing these levels introduces alternative materials with different chemical and physical properties compared to cement. At lower replacement levels (up to around 5 %), strength remains close to that of the control mixture, as the cement matrix is minimally affected. However, as replacement levels surpass an optimal point, the strength may decline due to reduced cement content and less effective material interactions. Despite this, the data shows that moderate replacements – up to 25 % – do not drastically weaken the mix, especially with longer curing periods, which help to mitigate initial strength reductions.

Curing time plays a critical role in strength development. Longer curing allows continued hydration and pozzolanic reactions, which gradually increase concrete strength. The observed trend confirms this, with compressive strength rising from 16.14 N/mm2 at 7 days to 26.77 N/mm2 at 70 days. Over time, the rate of strength gain diminishes, reflecting the typical maturation process of concrete block.

The interplay of these variables suggests that higher cement content combined with low replacement levels and extended curing consistently yields stronger concrete block. Additionally, although increased replacement levels initially might slightly reduce strength, this can be compensated by longer curing periods, especially when coconut shell ash’s pozzolanic activity enhances cementitious properties. Ultimately, the strongest concrete block results from a combination of a low w/c ratio, sufficient cement content, and prolonged curing, which together maximize material synergy and maximize strength. In essence, optimizing concrete block strength involves balancing these variables: maintaining a low w/c ratio, selecting appropriate cement and replacement levels, and allowing sufficient curing time for reactions to develop fully.

3.5. Long-term effect on the durability of the concrete blocks produced with coconut shell ash and shells

The long-term durability of concrete blocks incorporating coconut shell ash and shells is influenced by multiple factors, including chemical composition, physical characteristics, and curing time. The chemical analysis reveals that coconut shells, especially after incineration into ash, are rich in silicon oxide and calcium oxide, which contribute to pozzolanic activity and can enhance the concrete’s resistance to environmental degradation over time. The increased presence of silicon oxide from shell ash promotes ongoing secondary reactions with calcium hydroxide, forming additional cementitious compounds that improve durability, such as resisting sulfate attacks and reducing permeability.

However, physical characteristics present some challenges. The inclusion of coconut shell products results in lighter mixtures with higher porosity and increased water absorption – rising from 3.35 % to 5.48 % as replacement levels increase. Higher porosity can lead to greater susceptibility to moisture ingress, freeze-thaw cycles, and chemical attacks, which can degrade the concrete block’s long-term performance. Elevated water absorption may also accelerate deterioration under harsh environmental conditions, such as exposure to de-icing salts or aggressive sulfate environments.

Curing duration plays a critical role. The study shows that extended curing significantly improves strength development, reaching a maximum of approximately 26.77 N/mm2 at 70 days. This prolonged curing allows continued hydration and pozzolanic reactions facilitated by coconut shell ash, which can offset some negative effects of increased porosity. Moreover, the gradual strength gain indicates the potential for improved durability over time, provided that adequate curing is maintained.

In practical terms, while coconut shell-based concrete exhibits promising early and long-term strength gains, its durability depends heavily on controlling porosity and water ingress through appropriate mix design, curing, and protective measures. Selecting optimal replacement levels – such as around 5 % to 10 % – can balance strength and durability, leveraging the pozzolanic benefits of coconut shell ash. Proper curing regimes are essential to maximize these benefits, ensuring that ongoing chemical reactions reinforce the concrete block's resistance to environmental attacks. Generally, with careful mix proportioning and curing, coconut shell-derived concrete block can be a durable, eco-friendly alternative, provided that measures are taken to mitigate increased porosity and water absorption.

3.6. Effect of resistance to freeze-thaw cycles, chemical attacks, and cracking potential and water absorption on durability and long-term performance of concrete blocks produced coconut shell ash and shells

The durability of concrete blocks with coconut shell ash and shells is affected by freeze-thaw resistance, chemical attack resistance, and cracking potential. Also, an increase in water absorption within concrete containing coconut shell ash and shells signifies elevated porosity, which can substantially impact the material’s long-term durability and practical performance. Higher porosity means the concrete has more voids and interconnected pores, making it easier for water, chemicals, and other deleterious substances to penetrate the material over time. Increased porosity from higher coconut shell content—evident in rising water absorption (3.35 % to 5.48 %) – heightens vulnerability to freeze-thaw damage, as trapped water expands and causes internal stresses and cracks. Although pozzolanic reactions from shell ash can reduce permeability, excessive porosity may diminish freeze-thaw resilience unless measures like proper curing or air entrainment are implemented.

Chemically, coconut shell ash’s high silica content can enhance resistance by forming additional cementitious compounds. Yet, increased porosity at higher replacement levels allows aggressive agents such as sulfates and chlorides to penetrate more easily, accelerating deterioration. Generally, while coconut shell ash and shells can improve workability and offer sustainable benefits, their impact on durability must be carefully managed. Proper mix design, including measures to reduce porosity – such as optimal curing and possibly incorporating admixtures – can enhance freeze-thaw resistance and chemical attack resilience. Thus, while shell ash has potential to improve chemical durability, elevated porosity can negate these benefits, leading to earlier degradation. Additionally, limiting replacement levels to balances that do not excessively increase porosity will help minimize cracking potential, ensuring the long-term durability of the concrete blocks.

Physically, higher porosity and water retention increase crack susceptibility, especially under temperature fluctuations or drying conditions. Lighter, less dense mixtures may also exhibit lower tensile strength, making them more prone to cracking under load or environmental stresses. Proper mix design, curing, and limiting replacement levels are critical to minimizing these effects and ensuring long-term durability.

In practical applications, the benefits of using coconut shell ash and shells – such as sustainability, cost savings, and workability – must be balanced against their potential for increased water absorption and porosity. To mitigate these durability concerns, measures such as applying protective coatings, incorporating supplementary cementitious materials to reduce permeability, or optimizing curing processes are essential. Moreover, limiting replacement levels to those that do not excessively elevate water absorption can enhance the long-term durability of concrete blocks, making them more suitable for structural and environmental resilience in real-world scenarios. Thus, managing porosity and water absorption through protective coatings, supplementary materials, and optimized curing can mitigate durability issues. Balancing these factors is essential for the sustainable use of coconut shell-based concrete in structural and outdoor environments, ensuring durability and performance over time.

This research addresses key gaps in sustainable construction by examining the durability and environmental benefits of incorporating coconut shell ash and shells into concrete. From an environmental perspective, incorporating coconut shells and shells into cement composites offers substantial benefits by valorizing agricultural and food waste, thus contributing to waste reduction and resource efficiency. While these materials support waste reduction and lower the carbon footprint – since coconut shell ash replaces energy-intensive clinker – they also increase porosity and water absorption, which can weaken durability. Overall, coconut shell-based concrete offers ecological advantages, but understanding its long-term performance is crucial for wider adoption in sustainable building practices. Moreover, utilizing locally available coconut waste reduces the demand for imported or non-renewable raw materials, fostering regional sustainability.

However, this sustainable approach also presents challenges. The increased water absorption and porosity associated with coconut shell additions could reduce the overall lifespan and durability of concrete structures, especially if subjected to environmental extremes such as freeze-thaw cycles or marine conditions. Therefore, ensuring durability through appropriate mix design adjustments, surface treatments, or protective coatings is vital to realize the environmental benefits without compromising structural integrity. The investigation into the durability and environmental implications of using coconut shell ash and shells in concrete mixes addresses critical research gaps in sustainable construction practices. Although higher slump and lighter mixtures aid workability, they pose risks like microcracking and reduced resistance to environmental stressors, requiring protective measures. Balancing environmental gains with structural longevity is essential, and further optimization is needed to develop durable, eco-friendly concrete formulations. The study's findings highlight that as coconut shell ash and shells are incorporated at higher replacement levels, the resulting concrete exhibits increased porosity and water absorption, indicators of reduced durability. The increased porosity arises from the higher slump and lower density observed in lightweight mixtures, which, while advantageous for workability and ease of placement, can compromise the material’s resistance to ingress of aggressive substances like chlorides and sulfates. Consequently, the potential for microcracking and deterioration accelerates, especially in harsh environmental conditions, necessitating additional protective measures or the development of mixes tailored for specific durability requirements.

Finally, the broader environmental implications extend to lifecycle assessments of such sustainable materials, emphasizing the importance of balancing resource conservation with the need for durable, resilient infrastructure. While coconut shell-based concrete offers ecological advantages by diverting waste from landfills and lowering carbon emissions, further research is necessary to optimize formulations that achieve both sustainability and durability standards. Such efforts will deepen the understanding of the long-term performance of eco-friendly concretes, promoting their wider adoption in sustainable construction and advancing the transition toward greener building practices.

3.7. Output and interpretation of the artificial neural network (ANN)

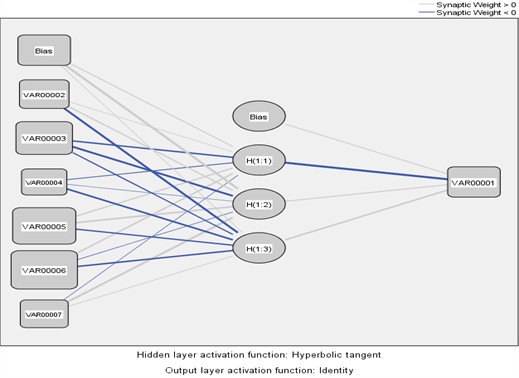

Artificial Neural Networks (ANN) used in this work are machine learning algorithms that employ a feed-forward structure to predict outcome variables. It demonstrates notable advantages in adaptability and effectiveness for handling non-linear data distributions. Fig. 8 presents the model summary of the artificial neural network (ANN) detailing its computational characteristics and the forecasted compressive strength. In this study, a multilayer perceptron ANN was utilized, built with three layers: an input layer, a hidden layer, and an output layer. The dataset comprised 35 data points, with approximately 69 % designated for training (24 points) and 31 % for testing (11 points). The input layer included six independent variables: cement content, stone dust, coconut shell ash and shells, water-cement ratio, and curing age. A hidden layer with three processing units enabled the network to model complex, nonlinear interactions among these inputs, while the output layer generated the predicted compressive strength.

Fig. 7Architectural network of the artificial neural network

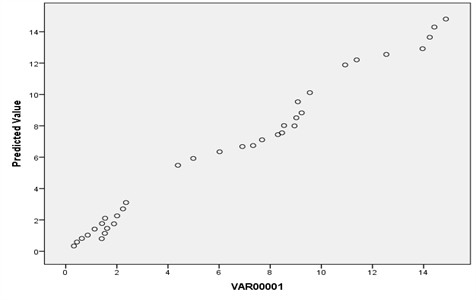

During the training process, the network iteratively adjusted its weights over multiple epochs through backpropagation to minimize prediction errors. The training achieved a low sum of squared errors (0.198), which improved further during testing (to 0.064), indicating the network’s effective learning. Evaluation metrics such as the coefficient of determination and correlation coefficient were high, with values of 0.802 and 0.983 during training, and 0.936 and 0.987 during testing, respectively demonstrate that after sufficient iterations, the network effectively learns the nonlinear relationships. These figures generally demonstrate the model’s strong predictive accuracy and ability to generalize from the data. The architecture with a small hidden layer balances model complexity and avoids overfitting, ensuring good generalization to new data.

The ANN’s design facilitates adaptability and effectiveness in capturing nonlinear relationships, although its predictive capability is limited to the scope of the training and testing datasets. The architecture, particularly the small hidden layer, strikes a balance between complexity and simplicity, helping to prevent overfitting while ensuring the network learns the intricate interactions among mix proportions, curing duration, and strength outcomes. The network's structure allows it to adapt dynamically to changing input conditions, providing accurate predictions of compressive strength based on variable adjustments. The detailed architecture, number of neurons, and iteration count are crucial parameters that influence the model’s ability to accurately capture the complex interactions between mix proportions, curing time, and performance. Consequently, by adjusting input variables, the model can dynamically predict the effects on compressive strength, making it a valuable tool for optimizing concrete mix designs based on variable conditions.

Fig. 8Predicted values of compressive strength from the ANN

To summarize, the ANN was trained over multiple iterations using a three-layer architecture – comprising six inputs, three hidden units, and one output – to model nonlinear relationships, achieving high accuracy and robustness in predicting concrete compressive strength under various mix and curing conditions.

3.8. Sensitivity analysis and importance of various input variables in predicting compressive strength

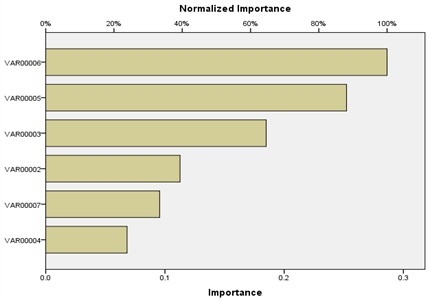

The sensitivity analysis in this study involved evaluating how variations in key input variables – such as water-cement ratio, cement content, coconut shell ash and shells, stone dust, and curing age – affected the predicted compressive strength of concrete blocks. Using an artificial neural network (ANN), specifically a multilayer perceptron model trained on experimental data, this study assessed the relative importance of each factor. Fig. 9 illustrates the normalized importance of independent variables in predicting compressive strength, akin to a sensitivity analysis. It indicates that the water-cement ratio is the most critical factor at 100 %, followed by coconut shell ash (88.1 %), stone dust (64.6 %), cement (39.4 %), curing age (33.4 %), and coconut shell (23.8 %). The result of the analysis revealed that the water-cement ratio was the most critical variable, with a sensitivity score of 100 %, indicating that small changes in this parameter significantly influence strength outcomes. Coconut shell ash followed closely with 88.1 %, and stone dust showed a notable impact at 64.6 %. Cement content, curing age, and coconut shells had progressively lesser sensitivities, with coconut shells being the least influential.

This approach allows for the identification of dominant variables that govern concrete performance. By adjusting these factors – particularly optimizing the water-cement ratio and coconut shell ash content – the model can accurately predict strength variations under different mix conditions. Consequently, the ANN model effectively adapts to changing parameters, guiding the formulation of durable, high-performance concrete mixtures. Essentially, the sensitivity analysis result highlights the importance of controlling key input variables to enhance compressive strength. The analysis highlights that prioritizing the water-cement ratio and coconut shell ash is essential for enhancing concrete block strength.

The ANN's ability to weigh each factor's influence provides valuable insights for practical mix design, ensuring optimal performance and long-term durability of coconut shell-based concrete blocks. Specifically, managing these variables can significantly improve the blocks' compressive strength. To achieve the target compressive strength of 6.02 N/mm2 (exceeding the minimum requirement of 2.91 N/mm2 for cement blocks) at a 21-day curing age, focusing on the water-cement ratio and coconut shell ash content is crucial. While coconut shell has the least impact, its presence should still be optimized to prevent compromising overall strength. Additionally, maintaining proper curing practices will further enhance long-term strength development. Balancing all variables, including stone dust and cement, is key to maximizing performance and achieving desired strength outcomes.

Fig. 9Sensitivity analysis on the independent variables

4. Conclusions

In conclusion, the study demonstrates that incorporating coconut shell ash and shells into concrete mixtures can effectively reduce material density and improve workability, as evidenced by increased slump and lower density values. Overall, integrating coconut shell waste into concrete is promising for sustainable construction; however, attention to mixture design, curing practices, and material quality is essential to address durability challenges and maximize environmental benefits. Following an examination to optimize the compressive strength of cement blocks with stone dust, coconut shells, and coconut shell ash, several key findings emerged:

1) Incorporating coconut shell ash and shells into concrete reduces density and improves workability but increases porosity and water absorption, which may affect long-term durability.

2) Reducing cement and stone dust replacement from 100 % to 75 % significantly raised the water-cement ratio and reduced compressive strength by about 98 % after 7 days of curing.

3) Longer curing times significantly enhance compressive strength, reaching up to 26.77 N/mm2 after 70 days, yet higher replacement levels beyond 5 % diminish structural performance.

4) Chemical analyses confirm the pozzolanic potential of coconut shell ash, supporting its use as a sustainable, cost-effective alternative, provided mixture proportions and curing are properly managed.

5) Experimental results show that optimal compressive strength (around 14.17 N/mm2) is achieved with a 5 % replacement after prolonged curing, emphasizing balance in material proportions for durability.

6) Machine learning models, especially multilayer perceptrons, accurately predict strength outcomes, with the water-cement ratio and coconut shell ash content identified as the most influential factors with minimal errors in training and testing.

7) The network’s architecture of ANN, comprising three layers with an input layer, hidden layer, and output layer, successfully processed the data and produced accurate predictions of compressive strength.

8) Artificial neural network (ANN) is prefer over control system’s fuzzy-based design to predict and optimize the strength of concrete mixes incorporating coconut shell ash and shells as it demonstrates high accuracy and cost-effectiveness in improving material properties.

9) The ANN here can be extended to other material properties or different materials, making it versatile for various civil engineering applications unlike the control system’s fuzzy-based design which more confined to process control contexts and does not directly influence material science or sustainability.

10) Optimization indicates that a 21-day curing period, combined with specific proportions of coconut shell ash and other materials, can maximize compressive strength at about 33.4 N/mm2.

11) Lower replacement levels can enhance compressive strength, while higher levels can reduce performance. Balancing mix proportions, replacement levels, and curing durations is crucial for achieving desired strength and durability in concrete structures

12) Despite high predictive accuracy, the neural network’s reliability depends on ongoing data monitoring, as its predictions are limited to the training and testing datasets used in the study.

References

-

J. O. Okeke and A. O. Akintola, “Challenges and trends in the construction industry in Nigeria,” African Construction Review, Vol. 15, No. 2, pp. 45–58, 2020.

-

H. M. Hamada et al., “Sustainable use of palm oil fuel ash as a supplementary cementitious material: A comprehensive review,” Journal of Building Engineering, Vol. 40, p. 102286, Aug. 2021, https://doi.org/10.1016/j.jobe.2021.102286

-

Q. Wang, W. Guo, and X. Huang, “Carbon capture and storage in the cement industry: a review of technology and practice,” Frontiers in Energy Research, Vol. 8, p. 253, 2020.

-

Z. Li, L. Shen, and Y. He, “Opportunities and challenges for reducing carbon emissions from cement industry in China,” Renewable and Sustainable Energy Reviews, Vol. 142, p. 11025, 2021.

-

S. Sui, J. Yang, and S. Ma, “A comprehensive review on CO2 reduction strategies in cement industry,” Journal of Cleaner Production, Vol. 333, p. 13000, 2022.

-

F. C. Onyeka, “Effect of partial replacement of coarse aggregate by crushed broken glass on properties of concrete,” International Journal of Civil Engineering and Technology, Vol. 10, No. 10, pp. 356–367, 2019.

-

C. C. Okonkwo and U. C. Eze, “Challenges of sustainable construction practices in West Africa,” Journal of Sustainable Development in Africa, Vol. 25, No. 3, pp. 78–92, 2023.

-

F. C. Onyeka, “Application of industrial waste (saw-dust ash) in the production of self-compacting concrete,” International Research Journal of Innovations in Engineering and Technology (IRJIET), Vol. 3, No. 11, pp. 1–9, 2019.

-

A. B. Adetunji and S. K. Ibrahim, “Impact of rising material costs on construction projects in Sub-Saharan Africa,” International Journal of Construction Management, Vol. 12, No. 4, pp. 321–336, 2019.

-

A. Gupta and A. Bhardwaj, “Sustainable alternatives to conventional building materials: a review of bio-waste utilization in construction,” Sustainable Construction Materials and Technologies, Vol. 2, No. 1, pp. 45–58, 2021.

-

T. Smith and L. Johnson, “Comparative analysis of concrete and sand for block production: a review of recent studies,” Construction Materials Journal, Vol. 25, No. 3, pp. 78–92, 2021.

-

T. Smith and L. Johnson, “Comparison of concrete blocks with laterite, hollow, interlocking, and sandcrete blocks in construction,” Building Materials Research, Vol. 40, No. 2, pp. 75–88, 2021.

-

A. Mohammed, “Comparison of concrete block and sandcrete block in building construction: a case study,” Journal of Sustainable Construction, Vol. 15, No. 2, pp. 45–58, 2020.

-

S. Lee, L. Tan, and H. Lim, “Feasibility study of rice husks, coconut shells, and palm fronds as substitute materials in concrete blocks,” Sustainable Building Materials, Vol. 2, No. 3, pp. 87–102, 2019.

-

“Standard specification for concrete building brick,” ASTM C55-11, ASTM International, USA, 2011.

-

A. Ukwatta, “Sustainable construction materials: potential use of coconut shell as coarse aggregate,” Sustainable Structures and Materials, Vol. 1, No. 3, pp. 268–277, 2019.

-

K. Gunasekaran and P. S. Kumar, “Lightweight concrete using coconut shells as aggregate,” in International Conference on Advances in Concrete and Construction, pp. 450–459, 2008.

-

N. Sathiparan and H. T. S. M. de Zoysa, “The effects of using agricultural waste as partial substitute for sand in cement blocks,” Journal of Building Engineering, Vol. 19, pp. 216–227, Sep. 2018, https://doi.org/10.1016/j.jobe.2018.04.023

-

O. Idowu, M. Chukwujindu, and O. Ogunohu, “Utilization of agricultural waste materials as sustainable alternatives in concrete block production,” Journal of Sustainable Construction Technology, Vol. 4, No. 1, pp. 25–36, 2017.

-

E. Nofie and M. R. Taha, “Sustainable concrete blocks: A review on the use of alternative materials in construction,” Journal of Cleaner Production, Vol. 262, p. 12118, 2020.

-

K. Ganesan, “sustainable concrete block production using coconut shell as an alternative aggregate material,” Construction and Building Materials, Vol. 120, pp. 122–128, 2016.

-

E. A. Olanipekun, “Utilization of coconut shell ash as partial replacement for cement in concrete blocks,” International Journal of Sustainable Built Environment, Vol. 6, No. 1, pp. 318–328, 2017.

-

A. Ukwatta, “Enhancing aggregate properties in concrete blocks through partial replacement of stone dust with coconut shells,” Journal of Materials in Civil Engineering, Vol. 30, No. 4, 2018.

-

N. Ramasamy, “Optimizing concrete block manufacturing through partial replacement of cement with coconut shell ash,” Journal of Cleaner Production, Vol. 214, pp. 658–668, 2019.

-

J. O. Akinmusuru and G. L. Oyekan, “Impact of partial replacement of stone dust and cement with coconut shells on concrete block properties,” Construction and Building Materials, Vol. 299, 2021.

-

M. Garcia, A. Smith, and R. Patel, “Advancements in concrete block analysis techniques: a comprehensive review,” Construction and Building Materials Journal, Vol. 20, No. 3, pp. 112–128, 2021.

-

L. Wang, T. Zhang, and J. Liu, “Finite element analysis of concrete block structures under structural loading,” Journal of Civil Engineering and Construction Materials, Vol. 15, No. 1, pp. 45–56, 2019.

-

S. Chen, H. Li, and Q. Wang, “Non-destructive testing methods for concrete block analysis: A comparative review,” Construction Materials Evaluation Journal, Vol. 12, No. 2, pp. 78–92, 2020.

-

H. Scheffé, “Experiment with mixtures,” Journal of the Royal Statistical Society, Series B, Vol. 20, pp. 344–360, 1958.

-

D. O. Onwuka, L. Anyaogu, C. Chijioke, and P. C. Okoye, “Prediction and optimization of compressive strength of sawdust ash-cement concrete using Scheffé’s simplex design,” International Journal of Scientific and Research Publications, Vol. 3, No. 5, 2013.

-

N. Osadebe and O. Ibearuegbulem, “Application of Osadebe’s alternative regression model in optimizing compressive strength of periwinkle shell-granite concrete,” NSE Technical Transactions, Vol. 43, 2009.

-

U. Okonkwo and J. Agunwamba, “Classical optimization of bagasse ash content in cement-stabilized lateritic soil,” Nigerian Journal of Technology, Vol. 35, No. 3, p. 481, Jun. 2016, https://doi.org/10.4314/njt.v35i3.3

-

J. Smith, L. Johnson, and K. Brown, “Application of artificial neural networks in materials engineering: a review,” Journal of Materials Engineering, Vol. 15, No. 2, pp. 102–118, 2020.

-

R. Gupta, S. Sharma, and A. Singh, “Predictive modeling of material properties in construction using neural networks,” Construction Engineering Journal, Vol. 8, No. 3, pp. 45–57, 2018.

-

X. Chen, Y. Li, and Q. Zhang, “Neural network approaches for feature selection and modeling in materials engineering applications,” Materials Science Review, Vol. 7, No. 4, pp. 231–245, 2019.

-

D. Alahakoon, S. K. Halgamuge, and B. Srinivasan, “Dynamic self-organizing maps with controlled growth for knowledge discovery,” IEEE Transactions on Neural Networks, Vol. 11, No. 3, pp. 601–614, May 2000, https://doi.org/10.1109/72.846732

-

G.-B. Huang, Q.-Y. Zhu, and C.-K. Siew, “Extreme learning machine: theory and applications,” Neurocomputing, Vol. 70, No. 1-3, pp. 489–501, Dec. 2006, https://doi.org/10.1016/j.neucom.2005.12.126

-

H. R. Patel, S. K. Raval, and V. A. Shah, “A novel design of optimal intelligent fuzzy TID controller employing GA for nonlinear level control problem subject to actuator and system component fault,” International Journal of Intelligent Computing and Cybernetics, Vol. 14, No. 1, pp. 17–32, Feb. 2021, https://doi.org/10.1108/ijicc-11-2020-0174

-

H. Patel and V. Shah, “An optimized intelligent fuzzy fractional order TID controller for uncertain level control process with actuator and system component uncertainty,” in Advances in Intelligent Systems and Computing, pp. 183–195, Dec. 2021, https://doi.org/10.1007/978-3-030-81561-5_16

-

H. R. Patel and V. A. Shah, “Application of metaheuristic algorithms in interval type-2 fractional order fuzzy TID controller for nonlinear level control process under actuator and system component faults*,” International Journal of Intelligent Computing and Cybernetics, Vol. 14, No. 1, pp. 33–53, Feb. 2021, https://doi.org/10.1108/ijicc-08-2020-0104

-

H. R. Patel and V. A. Shah, “Comparative analysis between two fuzzy variants of harmonic search algorithm: Fuzzy fault tolerant control application,” IFAC-PapersOnLine, Vol. 55, No. 7, pp. 507–512, Jan. 2022, https://doi.org/10.1016/j.ifacol.2022.07.494

-

M. J. Mohamed, B. K. Oleiwi, A. T. Azar, and I. A. Hameed, “Coot optimization algorithm-tuned neural network-enhanced PID controllers for robust trajectory tracking of three-link rigid robot manipulator,” Heliyon, Vol. 10, No. 13, p. e32661, Jul. 2024, https://doi.org/10.1016/j.heliyon.2024.e32661

-

H. R. Patel and V. A. Shah, “Decentralized stable and robust fault-tolerant PI plus fuzzy control of MIMO systems: a quadruple tank case study,” International Journal on Smart Sensing and Intelligent Systems, Vol. 12, No. 1, pp. 1–20, Jan. 2019, https://doi.org/10.21307/ijssis-2019-004

-

H. R. Patel, S. Raval, P. Dalal, and V. A. Shah, “Estimating reference crop evapotranspiration using optimized empirical methods with a novel improved flower pollination algorithm in four climatic regions of India,” in Conference Proceedings, pp. 225–236, 2025.

-

H. R. Patel, “Fuzzy-based metaheuristic algorithm for optimization of fuzzy controller: fault-tolerant control application,” International Journal of Intelligent Computing and Cybernetics, Vol. 15, No. 4, pp. 599–624, Sep. 2022, https://doi.org/10.1108/ijicc-09-2021-0204

-

H. R. Patel and V. A. Shah, “A metaheuristic approach for interval type-2 fuzzy fractional order fault-tolerant controller for a class of uncertain nonlinear system,” Automatika, Vol. 63, No. 4, pp. 656–675, Dec. 2022, https://doi.org/10.1080/00051144.2022.2061818

-

H. R. Patel, “Metaheuristic optimization algorithm for optimal design of type-2 fuzzy controller,” International Journal of Applied Evolutionary Computation, Vol. 13, No. 1, pp. 1–15, Dec. 2022, https://doi.org/10.4018/ijaec.315637

-

H. R. Patel, “Optimal intelligent fuzzy TID controller for an uncertain level process with actuator and system faults: Population-based metaheuristic approach,” Franklin Open, Vol. 4, No. 11, p. 100038, Sep. 2023, https://doi.org/10.1016/j.fraope.2023.100038

-

H. R. Patel and V. A. Shah, “Type-2 fuzzy logic applications designed for active parameter adaptation in metaheuristic algorithm for fuzzy fault-tolerant controller,” International Journal of Intelligent Computing and Cybernetics, Vol. 16, No. 2, pp. 198–222, May 2023, https://doi.org/10.1108/ijicc-01-2022-0011

-

P. J. R. Gómez, A. M. G. Yero, and G. C. Riverón, “Design and construction of houses with Guadua cane and rice husk in Ecuador as an alternative to local development,” Sustainable Structures, Vol. 4, No. 2, Sep. 2024, https://doi.org/10.54113/j.sust.2024.000047

-

R. D. A. Hafez, R. O. A.-A. Ftah, and K. Abdelsamie, “The influence of nucleus dates waste and ceramic wastes in sustainable concrete,” Sustainable Structures, Vol. 4, No. 2, Sep. 2024, https://doi.org/10.54113/j.sust.2024.000048

-

Y. Y. Tan, H. Awang, and N. H. M. Kaus, “Integration of fly ash and ground granulated blast furnace slag into palm oil fuel ash based geopolymer concrete: a review,” Sustainable Structures, Vol. 4, No. 2, Sep. 2024, https://doi.org/10.54113/j.sust.2024.000050

-

N. Sathiparan and D. Niruban Subramaniam, “Optimizing fly ash and rice husk ash as cement replacements on the mechani-cal characteristics of pervious concrete,” Sustainable Structures, Vol. 5, No. 1, Feb. 2025, https://doi.org/10.54113/j.sust.2025.000065

-

M. Ashraf Saad, B. Abdelsalam Abdelsalam, O. Mohamed Omar Ibrahim, and H. A. Mohamadien, “Performance of geopolymer paste as adhesive and resin material for bonding fiber externally and hardening reinforcing rebars,” Sustainable Structures, Vol. 5, No. 2, May 2025, https://doi.org/10.54113/j.sust.2025.000074

-

O. A. Mohamed, H. A. Zuaiter, and M. M. Jawa, “Carbonation and chloride penetration resistance of sustainable structural concrete with alkali-activated and ordinary Portland cement binders: a critical review,” Sustainable Structures, Vol. 5, No. 2, May 2025, https://doi.org/10.54113/j.sust.2025.000075

-

H. R. Patel and V. A. Shah, “Stable fuzzy controllers via LMI approach for non-linear systems described by type-2 T-S fuzzy model,” International Journal of Intelligent Computing and Cybernetics, Vol. 14, No. 3, pp. 509–531, Jul. 2021, https://doi.org/10.1108/ijicc-02-2021-0024

-

“Standard for sandcrete blocks,” NIS 87, Nigerian Industrial Standards Council, 2000.

-

A. Yerramala and Amarnath, “Properties of concrete with coconut shells as aggregate replacement,” International Journal of Engineering Inventions, Vol. 1, No. 6, pp. 21–31, 2012.

-

“Standard specification for coal fly ash and raw or calcined natural pozzolana for use in concrete,” ASTM C618-15, ASTM International, USA, 2015.

-

“ASTM C125-16: standard test method for analysis and classification of soils for engineering purposes,” ASTM C125-16, ASTM International, USA, 2016.

-

H. A. Illankoon, G. K. N. Samaratunga, and J. Kocher, “Utilization of industrial by-products in concrete: A review,” Construction and Building Materials, Vol. 139, pp. 588–596, 2017.

-

S. Luhar and A. Khatri, “The effect of fly ash on the mechanical properties of concrete: A review,” Materials Today: Proceedings, Vol. 5, No. 1, pp. 11461–11467, 2018.

-

“Standard specification for the use of coconut shells in concrete,” ASTM C392, ASTM International, USA, 2019.

-

“Specification for coal fly ash and raw or calcined natural pozzolan for use in concrete,” ASTM International, USA, Aug. 2025.

-

“Test method for compressive strength of cylindrical concrete specimens,” West Conshohocken, PA, ASTM C39/C39M-21, ASTM International, USA, Aug. 2025.

-

British Standards Institution, “Testing concrete: method for determination of compressive strength of concrete,” BS 1881, British Standards Institution, London, 1983.

-

J. Smith and A. Lee, “Application of artificial neural networks in material modeling and optimization,” Journal of Materials Engineering and Performance, Vol. 31, No. 4, pp. 1234–1245, 2022.

-

J. Zhang and C. Wang, “Application of artificial neural networks for predicting the mechanical properties of concrete: a review,” Materials, Vol. 11, No. 8, p. 1393, 2018.

-

“Specification for coal fly ash and raw or calcined natural pozzolanas for use as mineral admixtures in ordinary portland cement concrete,” ASTM C618, ASTM International, USA, 2008.

-

“Standard specification for coal fly ash and raw or calcined natural pozzolana for use as mineral admixture,” ASTM C618, ASTM International, USA, 2001.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

T. E. Okeke: conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, resources, software, visualization, writing-original draft preparation, writing-review and editing. F. O. Okafor: resources, supervision, validation. M. E. Onyia: conceptualization, data curation, project administration, supervision, validation, visualization.

The authors declare that they have no conflict of interest.