Abstract

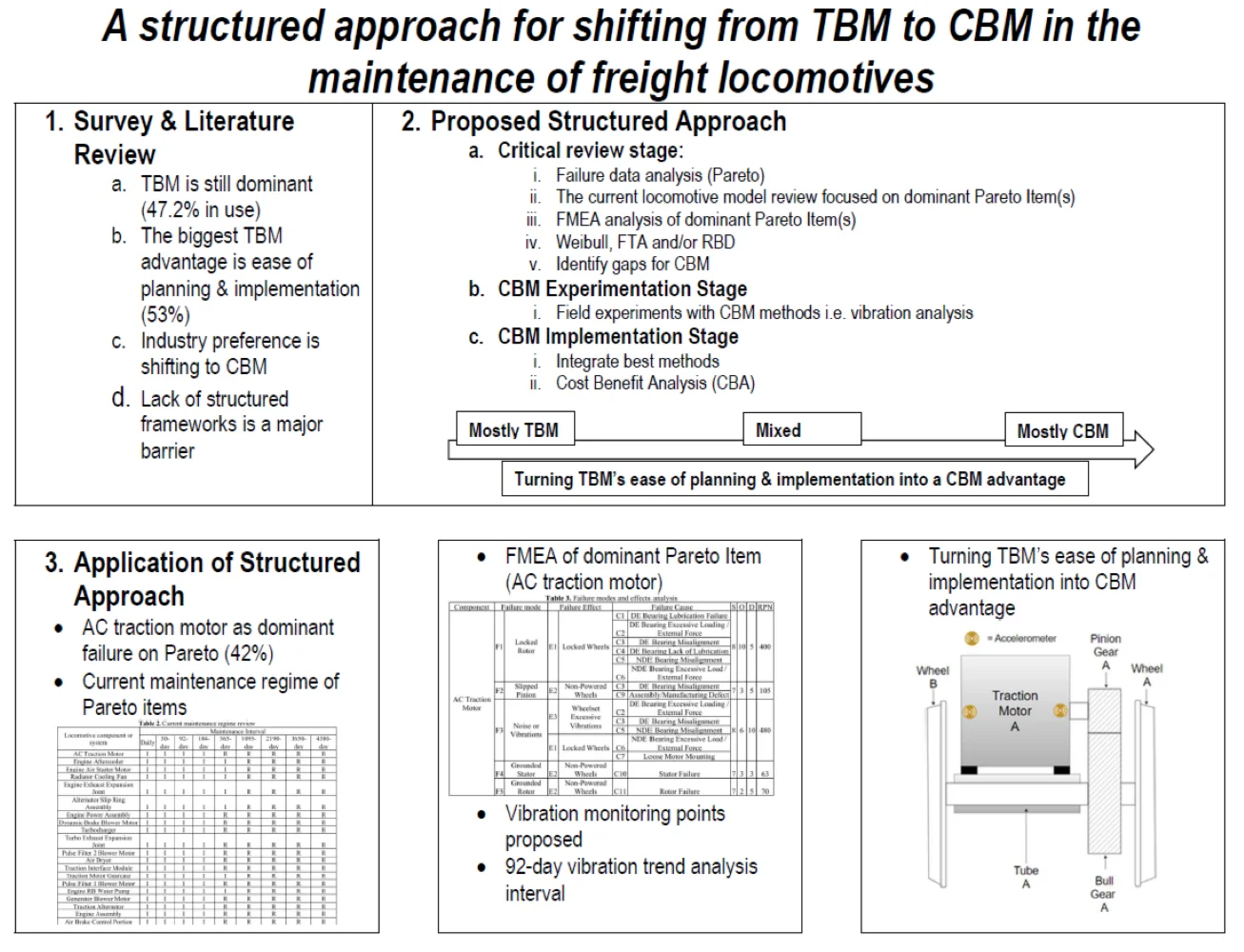

This paper presents findings from a survey into locomotive and train maintenance professionals’ insights about their current maintenance approaches and a short review of existing research literature to help provide greater understanding of why Time-based-maintenance (TBM) approaches are still dominant in the industry. Following that, a structured Condition-based-Maintenance (CBM) approach for freight locomotives’ maintenance that can be implemented to either complement or completely replace conventional TBM approaches adopted by the rail freight industry today is proposed. The foundation and most significant component of this approach is the critical review of the existing TBM regime, and the historical failure data using techniques such as Pareto Analysis and FMEA (Failure Mode & Effect Analysis). Once the critical review is completed, the structured approach experimentation and implementation stages can begin, which consist of the deployment of sensors and CBM techniques to detect problems on the locomotive by monitoring parameters such as vibration. An example of the structured approach application in the critical review stage is included in this paper using real failure data. The paper concludes with suggested future work to enable transition from TBM to CBM with a focus on components with the greatest impact on the maintenance organizational profitability.

Highlights

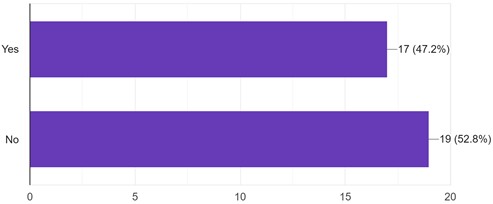

- TBM in freight locomotives maintenance is still dominant (47.2% in use).

- The biggest TBM advantage is ease of planning & implementation (53%).

- Lack of structured frameworks is a major barrier.

- Structured approach proposal offers a framework to turn ease of planning and implementation into CBM advantage.

- Application of structured approach using real life locomotive failure data included in this paper.

1. Introduction

Freight locomotives that are used to pull intermodal and bulk material cargo today still mostly follow a periodic Preventative Maintenance (PM) strategy which is mainly based on inspections, component cleaning, component replacements and overhauls at fixed intervals also known as TBM or Time-Based-Maintenance [1]. Condition-Based Maintenance (CBM) as a strategy in the freight locomotives industry has existed for a long time and multiple attempts of its application already exist in both industry and academic literature. For example, prior study dating as far back as 1995 by K N Fry from British Rail Research investigated using CBM to improve the reliability of Class 47 locomotive reliability [2].

The main objectives of this work are to determine the best answer to the question of why CBM has not been adopted as a main strategy for freight locomotives maintenance until today? In other words, why is TBM still dominant in the maintenance of freight locomotives? And based on the assumption that CBM is the better approach, what is the best practical approach that freight locomotive businesses can take to expand the adoption of CBM maintenance in their already existing TBM regimes? This study attempts to answer these questions in two ways as follows:

1) Firstly, through literature review, to summarize the advantages and disadvantages of TBM in contrast to CBM and then consider similar studies that tried to answer the same questions. The literature review to identify similar studies was done through online searches of journals such as ScienceDirect, Google Scholar, Extrica, MDPI, Hindawi and Sage Journals for the years 1990 to 2022.

2) Secondly, through surveying the opinions of professionals in the locomotive and train maintenance industry with questions that were designed based on the key advantages and disadvantages of TBM and CBM review discussed in the previous section.

The paper is presented as follows: introduction, literature review, maintenance organizations survey and discussion of survey responses, the structured approach methodology overview, the current maintenance model and descriptions of the three stages of the structured approach namely critical review, experimentation and implementation stages respectively. The approach is demonstrated in Section 6; however, this demonstration only includes the critical review stage of the structured approach, which is the biggest limitation of this study. Finally, conclusions are drawn in Section 7.

2. Literature review

The advantages of TBM include being a tried and tested strategy that has yielded the reliability required by operators and customers of freight trains for many decades and the ease of maintenance planning and execution based on a fixed set of maintenance activities [3]. The disadvantages of TBM include sharply increased cost of maintenance as the number of maintenance activities increases, and locomotives must be made unavailable to perform maintenance that may not be truly required which increases downtime [4]. The biggest disadvantage of CBM on the other hand is introducing more complicated maintenance planning as execution is based mostly on predictions [5]. However, in a CBM regime only when the health of the locomotive begins to deteriorate, the locomotive is removed from service and maintenance is performed, and when done over the service life of the locomotive results in a sharply decreased maintenance cost [6]. Similar studies that discussed the issue of slow CBM adoption in industry includes one carried out by Rosmaini and Shahrul (2012) who concluded that CBM is the favorable approach, but more research is needed to make CBM more realistic for industrial practice. Another study by Verhagen, et al. (2023) discussed the challenges to slow CBM adoption in the Aviation industry, and they concluded that even with big strides made in condition monitoring technology reseach, adoption of CBM is behind due to lack of practical frameworks that explain how to adapt current maintenance procedures for CBM. The work in this paper is intended as contribution to fill the gap in industrial application of CBM research in general and freight locomotives maintenance research in particular with the main argument of this paper being that CBM adoption in freight locomotives maintenance can be achieved with a clear and structured approach that demonstrates how to introduce CBM to an already existing and mostly TBM regime and that the lack of such structured approach is the main reason for the slow adoption of CBM in the locomotive maintenance industry.

3. Maintenance organizations survey

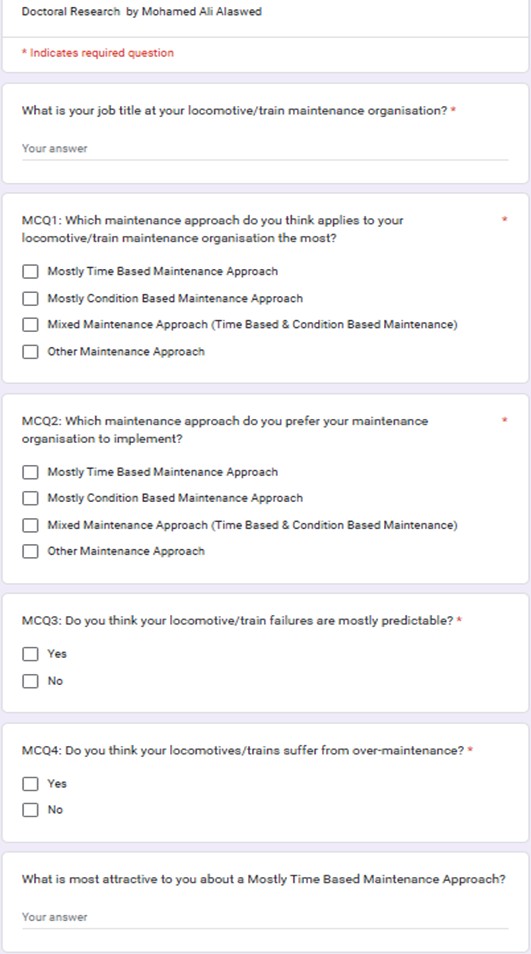

The author designed a qualitative questionnaire that consists of six questions, the first and last are open-ended questions, aimed at capturing the job titles of the participants and understanding what they found most advantageous about TBM. The other four questions were Multiple-Choice Questions (MCQs) aimed at understanding the perceptions of individuals in organizations in charge of locomotive and train maintenance with regards to their current and preferred maintenance approaches. These perceptions are crucial in this research to reinforce the widely reported assertions that TBM is still more dominant and that CBM is the preferred approach by industry. Google Forms was used to create the survey, a preview of it is shown in Fig. 1.

The target audience for this survey were members of locomotive and train maintenance organizations and the invitations to participate in the survey were focused on a selection of participants from locomotive and train maintenance organizations known to the author. The invitations were sent through email and through professional networking sites such as LinkedIn, with a target response rate of at least 30 participants.

Fig. 1Survey questions preview

3.1. Discussion of survey responses

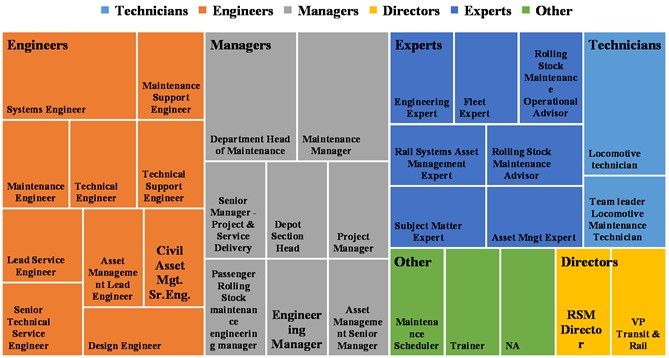

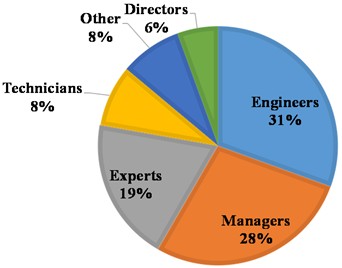

A total of 36 responses were received, representing multiple layers of employment within locomotive and train maintenance organizations such as technicians, engineers, managers and directors as well as maintenance experts, trainers and schedulers. Fig. 2 shows a tree map of the participants’ job titles and Fig. 3 shows the distribution of job titles.

Notably, engineers and maintenance managers represent the most responses at 31 % and 28 % respectively, followed by maintenance experts at 19 % then technicians and others such as trainers and schedulers at 8 % each respectively and finally maintenance directors at 6 %.

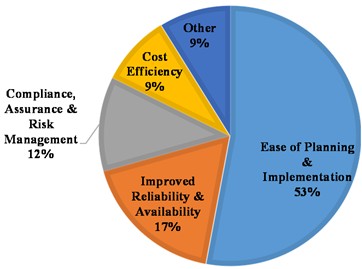

Fig. 4 shows a distribution of what the participants in this survey thought was most advantageous about the TBM portion of their current maintenance regimes.

Fig. 2Survey participants tree map

Fig. 3Survey distribution of job titles

Fig. 4Survey TBM advantages distribution of responses

Notably Ease of planning and Implementation represents the most responses at 53 %, followed by Improved Reliability and Availability and Compliance, Assurance and Risk Management at 17 % & 12 % respectively. Cost efficiency and other miscellaneous responses came last at 9 % each.

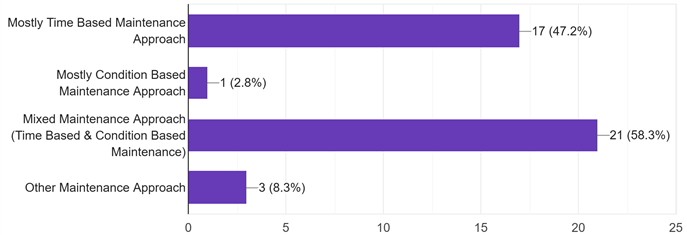

Fig. 5 shows a summary of the responses to MCQ1 which asked about the type of maintenance approach each participant thought was in adoption by their organization. The Mixed Maintenance approach that included both TBM & CBM came first at 58.3 %, followed by TBM at 47.2 % then came other maintenance approaches i.e. RCM (Reliability-Centered-Maintenance) or PdM (Predictive-Maintenance) and finally a mostly CBM approach at 2.8 %. Based on these responses, TBM is still highly adopted as almost half the responses (47.2 %) noted mostly TBM as their current approach.

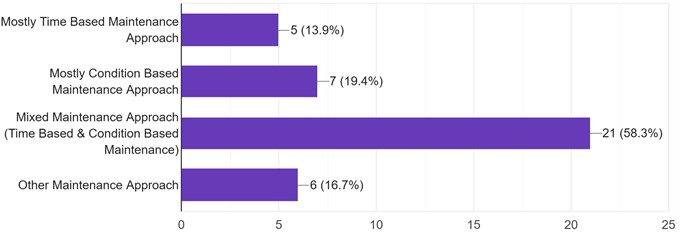

Fig. 6 shows a summary of the responses to MCQ2 which asked about the type of maintenance approach each participant preferred their organization to implement. Mixed maintenance approach came first at 58.3 %, followed by mostly CBM at 19.4 % then others such as RCM & PdM at 16.7 % and finally a mostly TBM approach at 13.9 %. Based on these responses, notably, professionals in the industry prefer less adoption of mostly TBM approaches as only 13.9 % of participants noted mostly TBM as their preferred maintenance approach against 19.4 % that preferred mostly CBM approaches.

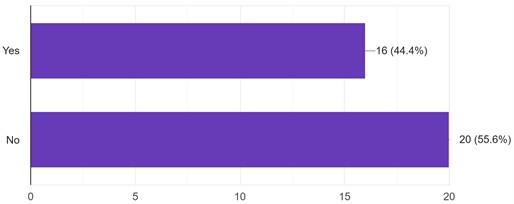

Fig. 7 shows a summary of the responses to MCQ3 which asked whether each participant thought their locomotive failures were predictable. 55.6% responded No, whereas 44.4% responded Yes.

Fig. 8 shows a summary of the responses to the final MCQ4 which asked whether each participant thought their locomotives suffered from over-maintenance. 52.8 % responded No whereas 47.2 % responded Yes.

Fig. 5Survey MCQ1 response summary

Fig. 6Survey MCQ2 Response Summary

Fig. 7Survey MCQ3 response summary

Fig. 8Survey MCQ4 response summary

4. The structured approach methodology

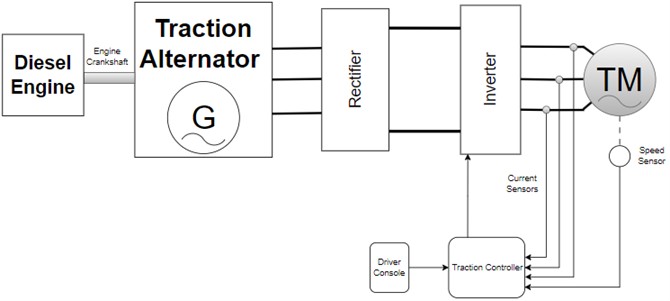

In this paper, a structured approach methodology to transition to CBM for freight locomotives is proposed, which can address the existing TBM model’s limitations. The TBM strategy considered for improvement in this paper belongs to a diesel-electric locomotive which is equipped with a Diesel Engine that turns a high-power Traction Alternator, Fig. 9 shows this arrangement.

Fig. 9Locomotive engine and traction alternator arrangement

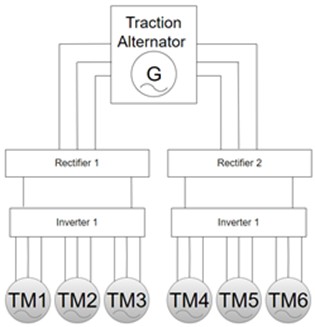

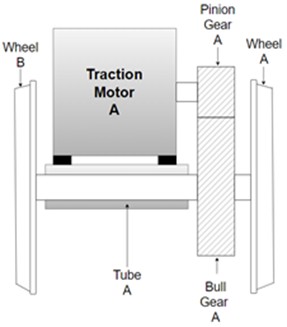

In most industries, the original version of the maintenance policy is derived from the OEM (Original Equipment Manufacturer) suggestions [6]. The original version of the locomotive maintenance regime in this paper is based on the manufacturer guidelines, which are mostly TBM. Later versions of the regime evolved with adjustments made by the locomotive operators and maintainers to address specific operating and performance requirements. To provide the reader with additional context about this locomotive in this study, the power generated by the locomotive Traction Alternator is fed to a group of electric traction motors, Fig. 10(a) shows this arrangement. Each traction motor is mechanically coupled to gears that rotate the locomotive wheels. Fig. 10(b) shows the motor and wheelset arrangement. Each set of three motors and three wheelsets form what is known as “motor bogie” or truck, the locomotive considered in this paper has two bogies or trucks [7].

Fig. 10a) Alternator and motors arrangement, b) motor and wheelset arrangement

a)

b)

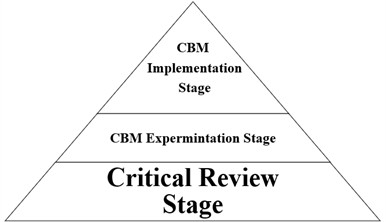

Fig. 11 shows the proposed CBM structured approach hierarchy with the critical review stage as its foundation. The structured approach is comprised of three main stages which are described in the following sections.

4.1. Current maintenance model

The TBM portion of the current maintenance model starts with a daily exam, followed by a 30-day inspection, and continues at a 30-day interval that consists of Inspections (I), Cleaning (C), and parts and consumables Replacements (R) such as lubricating oils, filters and seals. At 1095-days or 3 years of service life, the locomotive is stopped for its first major overhaul, which includes major locomotive parts and systems inspections (I), Cleaning (C), Replacements (R) and overhauls (O). The next major overhaul events happen as follows; 2190-days, or 6 years interval, 3285-days, or 9 years, 3650-days or 10 years and lastly, at 4380-days or 12 years of service-life.

Fig. 11Structured approach hierarchy

Each interval is represented in the maintenance specification document known as Maintenance Instruction or MI, which includes a set of maintenance tasks, where each task lists what locomotive parts and system to Inspect (I), Clean (C), or Replace (R). The list of locomotive spare parts in the maintenance specification document is known as Bill of Materials or BOM. Table 1 shows the BOM for one of the locomotive TBM events.

Table 1TBM event BoM (bill of materials)

Maintenance event | Part description | Part number | Quantity | Locomotive system | Action |

180 Days | Engine Air Filters | 12345 | 5 | Forced Air System | R |

180 Days | Engine Oil Filters | 12346 | 10 | Engine | R |

180 Days | Primary Fuel Filter | 12347 | 1 | Engine | R |

180 Days | Main Generator Brushes | 12348 | 6 | Electrical Equipment | R |

180 Days | Main Reservoir Air Filters | 12349 | 2 | Compressed Air | R |

As revealed by the survey in this study, Ease of planning and implementation is what most maintenance organization professionals consider the biggest advantage about TBM. Fig. 12 shows the overhaul schedule performance charts adopted by the maintenance organization in this study, which include the schedule dates, the plan completion date and actual completion statuses.

Fig. 12TBM events plan and execution performance charts

4.2. Critical review stage

In this stage the locomotive historical failure data is analyzed using the Pareto analysis technique which is also known as the 80-20 rule [8]. What follows is the critical review and analysis of the existing TBM regime in relation to the failure data represented in the Pareto analysis; doing this will enable more understanding of the strengths and weaknesses of the current regime and potentially the obstacles that could hinder the implementation of CBM.

The next step is the critical review using Failure Modes and Effects Analysis (FMEA) tool, which is the primary analytical tool in the proposed structured approach, because it is a systematic tool and can reveal all the failure modes, causes of failure, and the effects of failures better than all other techniques [3].

Other techniques are also considered in the proposed structured approach, namely, Weibull analysis for being one of the best tools to reveal the characteristic life of failed components and to help in establishing a more precise failure rate baseline that can be used to perform other analytical techniques such as Fault Tree Analysis (FTA) and Reliability Block Diagram (RBD). FTA & RBD are effective in modelling the causes and effects of failures on the overall system or component reliability, which is something FMEA and Weibull cannot provide [3]. The final step of the critical review stage is to identify gaps in the existing maintenance regime where CBM can be implemented.

4.3. CBM experimentation stage

This is about experimenting with practical condition monitoring methods that can be performed by maintenance teams within locomotive workshop environments or onboard locomotives or even using wayside systems by monitoring parameters such as vibrations, temperatures, pressures, voltage, current acoustic emissions, and other parameters. This stage includes performing in-service testing and reviewing results and findings.

4.4. CBM implementation stage

This includes selecting the most appropriate and effective condition monitoring methods based on results in experimentation stage and its integration into the existing maintenance regime. Maintenance organizations use budgets for cost control [3], therefore performing a Cost Benefit Analysis (CBA) to analyze the risks and the benefits of the selected CBM method to be implemented are necessary and will be included in this stage.

5. Application of the structured approach

5.1. Historical failure data – pareto analysis

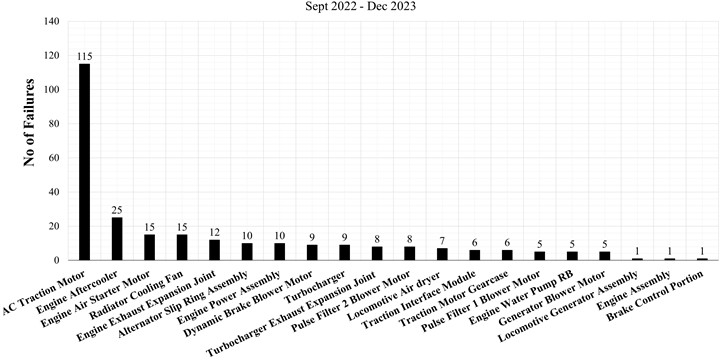

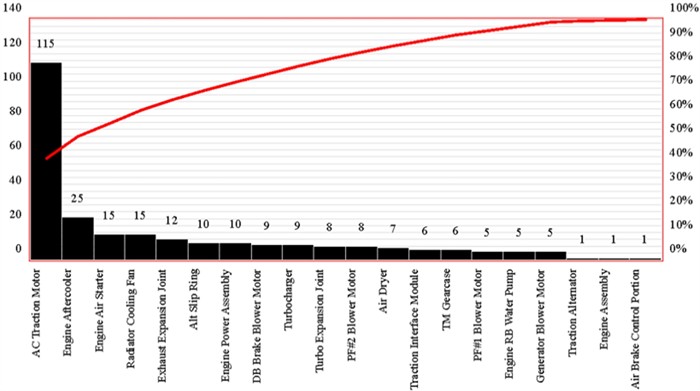

Pareto analysis of locomotive component failures data between September 2022 and December 2023 for the locomotive in this case study is performed. Fig. 13 shows the top 20 locomotive failures during this period.

The Pareto analysis shown in Fig. 14 is based on the frequency of each locomotive component failure and shows that the first nine locomotive component failures contribute to approximately 80 % of all failures with AC traction motor as the most dominant component failure (42 %).

5.2. Critical review of current maintenance regime

Table 2 shows all 20 maintenance components represented in Fig. 14 with details of the type of TBM task that is carried out during each interval. Notably, the electric AC traction motors that feature as the dominant failure in the Pareto analysis get overhauled during the 1095-day or 3 years interval. At 3650-days or 10 years, the locomotive bogies and all their sub-assemblies are overhauled and finally at 4380-days of service-life, the main traction alternator is overhauled.

Fig. 13Locomotive historical components failures – Top 20

Table 2Current maintenance regime review

Locomotive component or system | Maintenance Interval | ||||||||

Daily | 30-day | 92-day | 184-day | 365-day | 1095-day | 2190-day | 3650-day | 4380-day | |

AC Traction Motor | I | I | I | I | R | R | R | R | R |

Engine Aftercooler | I | I | I | I | I | R | R | R | R |

Engine Air Starter Motor | I | I | I | I | I | R | R | R | R |

Radiator Cooling Fan | I | I | I | I | I | R | R | R | R |

Engine Exhaust Expansion Joint | I | I | I | I | I | R | R | R | R |

Alternator Slip Ring Assembly | I | I | I | I | I | R | R | R | R |

Engine Power Assembly | I | I | I | I | R | R | R | R | R |

Dynamic Brake Blower Motor | I | I | I | I | R | R | R | R | R |

Turbocharger | I | I | I | I | R | R | R | R | R |

Turbo Exhaust Expansion Joint | I | I | I | I | R | R | R | R | R |

Pulse Filter 2 Blower Motor | I | I | I | I | R | R | R | R | R |

Air Dryer | I | I | I | I | R | R | R | R | R |

Traction Interface Module | I | I | I | I | R | R | R | R | R |

Traction Motor Gearcase | I | I | I | I | I | R | R | R | R |

Pulse Filter 1 Blower Motor | I | I | I | I | R | R | R | R | R |

Engine RB Water Pump | I | I | I | I | I | R | R | R | R |

Generator Blower Motor | I | I | I | I | R | R | R | R | R |

Traction Alternator | I | I | I | I | R | R | R | R | R |

Engine Assembly | I | I | I | I | R | R | R | R | R |

Air Brake Control Portion | I | I | I | I | R | R | R | R | R |

6. Failure mode and effects analysis (FMEA)

The Failure Mode and Effect Analysis (FMEA) is used to critically evaluate the most dominant failure in the Pareto Analysis, which is the AC motor failures as shown in Table 3. A list of potential failure modes pertaining to each category are identified using the terminology adopted by the freight industry to identify traction motor failures [23]. Rankings are set for the severity (S), the occurrence (O) and the detection (D) to allocate Risk Priority Number (RPN) values based on Eq. (1) [9]:

Fig. 14Failures Pareto analysis

Table 3Failure modes and effects analysis

Component | Failure mode | Failure Effect | Failure Cause | S | O | D | RPN | |||

AC Traction Motor | F1 | Locked Rotor | E1 | Locked Wheels | C1 | DE Bearing Lubrication Failure | 8 | 10 | 5 | 400 |

C2 | DE Bearing Excessive Loading / External Force | |||||||||

C3 | DE Bearing Misalignment | |||||||||

C4 | DE Bearing Lack of Lubrication | |||||||||

C5 | NDE Bearing Misalignment | |||||||||

C6 | NDE Bearing Excessive Load / External Force | |||||||||

F2 | Slipped Pinion | E2 | Non-Powered Wheels | C3 | DE Bearing Misalignment | 7 | 3 | 5 | 105 | |

C9 | Assembly/Manufacturing Defect | |||||||||

F3 | Noise or Vibrations | E3 | Wheelset Excessive Vibrations | C2 | DE Bearing Excessive Loading / External Force | 8 | 6 | 10 | 480 | |

C3 | DE Bearing Misalignment | |||||||||

C5 | NDE Bearing Misalignment | |||||||||

E1 | Locked Wheels | C6 | NDE Bearing Excessive Load / External Force | |||||||

C7 | Loose Motor Mounting | |||||||||

F4 | Grounded Stator | E2 | Non-Powered Wheels | C10 | Stator Failure | 7 | 3 | 3 | 63 | |

F5 | Grounded Rotor | E2 | Non-Powered Wheels | C11 | Rotor Failure | 7 | 2 | 5 | 70 | |

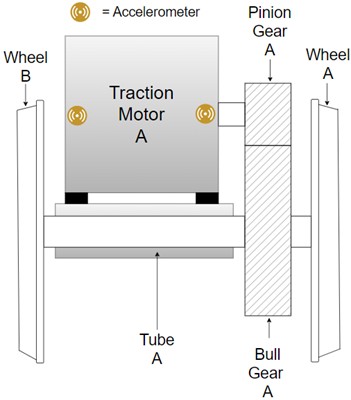

7. Identifying gaps for the CBM

AC traction motors are rotating components, understanding the vibration signature of rotary systems is a good choice for CBM [3]. Analysis of the current maintenance model revealed corrective actions already in place that are performed to detect C1 & C4 (lubrication failures) at intervals before the motor is removed for overhaul. C2 & C6 (excessive loading), C3 & C5 & C6 (misalignment) do not have any actions in the current maintenance model to detect them; besides they can all be considered CCFs (Common Cause Failures) with high vibration as the CCF (Common Cause of Failure). Therefore, in this paper, it is proposed that regular onboard vibration measurements should be conducted and vibration trend analysis performed.

The optimal interval for performing onboard vibration monitoring and trend analysis depends on several factors, such as the size of the fleet, the availability of locomotives to perform monitoring, the type of measuring equipment to be used and where to install it on the locomotive, but to start with, the proposed interval for performing onboard vibration measurements and trend analysis in the improved maintenance model is 92 days. This interval is to be reviewed after performing at least 20 vibration measurements per locomotive on a minimum of 10 different locomotives. The equipment to be used is to focus on the measurement of radial vibrations using accelerometers in two test points as shown in Fig. 15.

Fig. 15Accelerometers proposed locations for onboard vibration monitoring

8. Conclusions

In this paper, findings from a basic literature review and a survey into locomotive and train maintenance professionals’ insights about their current maintenance approaches and why TBM approaches are still preferred in the industry are presented. According to the results from the survey in this paper, TBM is still highly adopted by industry as 47.3 % of the responses selected mostly TBM as their current approach. Besides, there is clear support for less adoption of TBM in exchange for more CBM approaches according to maintenance professionals. This is particularly evident when professionals were asked what approach they preferred to be adopted, only 13.9 % selected a mostly TBM approach. On the other hand, one of the most notable findings from the literature review is that lack of structured approaches that explain how to adapt current maintenance procedures for CBM is one of the main reasons for its slow adoption by industry. Another important finding from the survey is that ease of planning and implementation is one of the biggest advantages of TBM in the opinions of maintenance professionals. Therefore, in this paper a structured approach to transition from a mostly TBM approach to a mostly CBM approach for freight locomotives is proposed. The structured approach is intended to make CBM easier to plan for and implement, thus turning one of the biggest advantages of TBM into one of the advantages of CBM. The structured approach consists of three stages namely, the Critical Review Stage, the CBM Experimentation Stage, and the CBM Implementation Stage. Only the critical review stage is demonstrated in this paper focusing on the frequency of failures and the most dominant failure, which is the AC Traction Motor. The marriage between frequently performing critical reviews of the existing TBM model and historical failures is the secret recipe of the structured approach presented in this paper. As future work, the proposed approach can be extended to demonstrate the CBM experimentation and implementation stages and to include more locomotive components. Moreover, the Pareto analysis can be expanded to be based on cost to address the components with the greatest impact on the profitability of the organization.

References

-

A. Barnes, “Increased locomotive performance using condition based maintenance,” in 6th IET Conference on Railway Condition Monitoring (RCM 2014), pp. 5.1.2–5.1.2, Jan. 2014, https://doi.org/10.1049/cp.2014.1011

-

K. N. Fry, “Diesel locomotive reliability improvement by system monitoring,” Proceedings of the Institution of Mechanical Engineers, Part F: Journal of Rail and Rapid Transit, Vol. 209, No. 1, pp. 1–10, Jan. 1995, https://doi.org/10.1243/pime_proc_1995_209_248_02

-

M. Ben-Daya, S. O. Duffuaa, A. Raouf, K. Jezdimir, and D. Ait-Kadi, Handbook of Maintenance Management and Engineering. London: Springer London, 2009, https://doi.org/10.1007/978-1-84882-472-0

-

W. Gao, Z. Zhang, Y. Zhou, L. Jiang, and W. Wang, “Maintenance optimization for a system with an implemented interval of replacement activities,” in International Conference on Quality, Reliability, Risk, Maintenance and Safety Engineering (QR2MSE), pp. 664–669, Jul. 2013, https://doi.org/10.1109/qr2mse.2013.6625665

-

W. J. C. Verhagen et al., “Condition-based maintenance in aviation: challenges and opportunities,” Aerospace, Vol. 10, No. 9, p. 762, Aug. 2023, https://doi.org/10.3390/aerospace10090762

-

R. Ahmad and S. Kamaruddin, “An overview of time-based and condition-based maintenance in industrial application,” Computers and Industrial Engineering, Vol. 63, No. 1, pp. 135–149, Aug. 2012, https://doi.org/10.1016/j.cie.2012.02.002

-

“Bogies.” The Railway Technical Website. http://www.railway-technical.com/trains/rolling-stock-index-l/bogies.html (accessed 2019).

-

B. B. Kunene and A. Telukdarie, “Analysis of failure mode effects of the traction motor,” in IEEE 28th International Conference on Engineering, Technology and Innovation (ICE/ITMC) and 31st International Association For Management of Technology (IAMOT) Joint Conference, No. 28th & 31st, pp. 1–6, Jun. 2022, https://doi.org/10.1109/ice/itmc-iamot55089.2022.10033308

-

J. D. Andrews and T. R. Moss, Reliability and Risk Assessment. New York: The American Society of Mechanical Engineers, 2002.

-

K. M. Watkins, “The integration of AC drive technology to Amtrak’s passenger locomotives,” in IEEE/ASME Joint Railroad Conference, 1993, https://doi.org/10.1109/rrcon.1993.292970

-

H. Sun, D. He, J. Zhong, Z. Wei, Z. Lao, and S. Shan, “Preventitive maintenance optimization for key components of subway train bogie with consideration of failure risk,” Engineering Failure Analysis, Vol. 154, No. 107634, 2023.

-

A. M. Smith, Reliability-centered maintenance. New York: McGraw- Hill, 1993.

-

C. Schneidhofer, K. Dubek, and N. Dörr, “Robust sensors enabling condition-based maintenance of lubricated components in locomotives and wagons,” Transportation Research Procedia, Vol. 72, pp. 3236–3243, Jan. 2023, https://doi.org/10.1016/j.trpro.2023.11.866

-

M. G. Mattos, D. A. Reis, and D. J. Magalhaes, “Locomotive’s spare parts optimization,” in IET International Conference on Railway Engineering, 2008.

-

A. Massaro et al., “Railway components wear: a smart platform for full traceability of maintenance activities,” in IEEE International Workshop on Metrology for Industry 4.0 and IoT (MetroInd4.0&IoT), pp. 237–241, Jun. 2021, https://doi.org/10.1109/metroind4.0iot51437.2021.9488486

-

C. Li, S. Luo, C. Cole, and M. Spiryagin, “An overview: modern techniques for railway vehicle on-board health monitoring systems,” Vehicle System Dynamics, Vol. 55, No. 7, pp. 1045–1070, Jul. 2017, https://doi.org/10.1080/00423114.2017.1296963

-

R. Kothamasu, S. H. Huang, and W. H. Verduin, “System health monitoring and prognostics – a review of current paradigms and practices,” Handbook of Maintenance Management and Engineering, Vol. 28, pp. 337–362, Jan. 2009, https://doi.org/10.1007/978-1-84882-472-0_14

-

N. Kahl, F. Thiery, R. Wohlrath, M. Rantatalo, C. Klien, and F. Gribi, “Deliverable D1.4 wayside vehicle monitoring for condition-based maintenance,” European Union Funding for Research and Innovation, 2022.

-

E. Fumeo, L. Oneto, and D. Anguita, “Condition based maintenance in railway transportation systems based on big data streaming analysis,” Procedia Computer Science, Vol. 53, pp. 437–446, Jan. 2015, https://doi.org/10.1016/j.procs.2015.07.321

-

V. T. Cang and D. D. Tuan, “Reliability based calculation of repairing interval of locomotive wheel axles,” in 9th International Conference on Fuzzy Systems and Knowledge Discovery (FSKD), pp. 780–784, May 2012, https://doi.org/10.1109/fskd.2012.6233983

-

E. Bernal, M. Spiryagin, and C. Cole, “Onboard condition monitoring sensors, systems and techniques for freight railway vehicles: a review,” IEEE Sensors Journal, Vol. 19, No. 1, pp. 1558–1748, Jan. 2019.

-

B. Baasch et al., “Deliverable D 3.5 Technologies for wagon monitoring systems,” European Union Funding for Research and Innovation, Jan. 2018.

-

M. A. M. Alaswed, and J. Sinha, “The development of a condition-based maintenance (CBM) framework for freight locomotives – AC traction motors case study,” Journal of Quality in Maintenance Engineering, 2025, https://doi.org/10.1108/JQME-03-2024-003

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Mohamed Alaswed: writing-review and editing, writing-original draft preparation, formal analysis conceptualization, investigation, software. Jyoti Sinha: supervision, conceptualization.

The authors declare that they have no conflict of interest.