Abstract

This study investigates the compaction and dynamic properties of rubber particle-loess from Inner Mongolia through laboratory tests, including compaction tests and dynamic triaxial tests. Four rubber particle sizes (10 mesh, 20 mesh, 40 mesh, and 100 mesh) and four contents (5 %, 10 %, 15 %, and 20 % by volume) were tested under varying conditions: confining pressures of 50 kPa, 100 kPa, and 200 kPa, and freeze-thaw cycles of 0, 1, 3, 6, and 9. The tests aimed to simulate environmental conditions relevant to infrastructure in Inner Mongolia's loess regions. Results revel that adding 5 % 40-mesh rubber particles maximized dynamic shear modulus, damping ratio, and compactness. The dynamic shear modulus exhibited strain-softening behavior, which decreased with increasing dynamic strain, rubber content, and freeze-thaw cycles, but increased with confining pressure. The damping ratio showed a non-linear relationship with moisture content, showing a minimum at optimum moisture and increasing with freeze-thaw cycles while decreasing with confining pressure. Notably, the damping ratio of rubber particle-loess consistently exceeded that of plain soil. These results highlight the potential of waste tire rubber particles as an eco-friendly material to enhance loess engineering properties, particularly in cold regions with significant freeze-thaw effects. The study provides a theoretical basis for improving loess stability and seismic performance in geotechnical applications.

Highlights

- Investigated the impact of waste tyre rubber particles on the compaction and dynamic properties of Inner Mongolia loess.

- Found that adding 5% 40-mesh rubber particles maximized the dynamic shear modulus, damping ratio, and compactness of loess.

- Revealed the complex effects of rubber particle content, size, confining pressure, and freeze-thaw cycles on loess performance.

- Provided a theoretical basis for using waste tyre rubber particles as an eco-friendly material to enhance loess engineering properties in cold regions.

- Offered scientific guidance for the application of rubber particle-loess in infrastructure construction in Inner Mongolia and other cold regions.

1. Introduction

Loess, prevalent in mid-latitude arid and semi-arid zones globally, is notably found in China's Loess Plateau, with Inner Mongolia being a key distribution area. Characterized by large pores and collapsibility [1], loess poses engineering challenges, especially under dynamic loads, impacting infrastructure like roads and railways [2], [3]. Thus, enhancing loess properties to boost its dynamic performance and engineering applicability is crucial [4], [5].

Rubber particles are increasingly used in soil improvement due to their elasticity and toughness, which enhance soil structure and strength [6], [7]. Many scholars have explored rubber particles' effects on soil mechanical properties. Deng et al. [8] incorporated rubber particles into sandy soil to improve the shear strength of sandy soil. Later rubber particles are also widely used in loess property improvement [9], [10]. Based on this, scholars in China and abroad have carried out detailed studies on rubber particles to improve the mechanical properties of loess. Hu et al. [11] added 11 % rubber powder and 8 % barite powder in loess and studied the changes of dynamic elastic modulus, dynamic shear modulus and damping ratio of Xi'an loess with the content of rubber powder and shear strain under the joint action of rubber powder and barite powder, which indicated that the seismic capacity of loess was enhanced by the adding of rubber powder and barite powder. Chai et al. [12] jointly applied rubber particles and EICP technology to study the effects of rubber particles on the dynamic properties of Xi’an loess using dynamic triaxial instrumentation. Chen et al. [13] analyzed the effect of using waste tyre rubber particles and enzyme-induced calcium carbonate precipitation (EICP) technology to improve the shear strength and shear strength indexes of loess in Xi'an area by using a straight shear test. Wang [14], Sun et al. [15] mixed fly ash, lime, and rubber particles together into loess to study its improvement performance on collapsible loess, and the results showed that the action of the three can improve the shear strength of loess. Kou et al. [16] used numerical simulation to study the compaction characteristics of rubber particle-loess, indicating that the addition of rubber particles in loess can improve its compactness. Assadollahi et al. [17] investigated the effects of different sizes and percentages of shredded rubber tires on the compaction and permeability properties of Memphis loess, finding that the dry unit weight of the soil/tire mixture decreased while permeability increased with higher tire content. Assadollahi et al. [18] further explored the consolidation properties of Memphis loess with varying amounts of crumb rubber, showing that crumb rubber significantly altered the soil's consolidation behavior, leading to higher settlements under low pressures but lower settlements under high pressures. These studies highlight the potential of rubber particles to improve soil performance in various engineering applications.

However, most existing studies combine rubber particles with other additives, not fully reflecting the impact of pure rubber particles. They also lack in-depth investigation into the effects of environmental conditions, such as moisture content, confining pressure, and freeze-thaw cycles on rubber particle-loess. Some studies only focus on the static properties of loess. Due to significant freeze-thaw effects, the degradation of loess engineering performance in Inner Mongolia is particularly prominent, but there is limited study on the interaction between waste tire rubber particles and loess under unique environmental conditions in the region. Consequently, this study focuses on improving loess in Inner Mongolia using waste tire rubber particles, considering factors like rubber particle size, content, and external environmental conditions such as moisture content, confining pressure, and freeze-thaw effects. Through dynamic triaxial tests, it explores the dynamic properties of rubber particle-loess under the unique environmental conditions of Inner Mongolia, particularly focusing on freeze-thaw effects. This study not only advances the understanding of rubber particle-loess interaction under freeze-thaw conditions, but also provides practical insights for engineering applications in similar cold regions, promoting sustainable development and effective resource utilization.

2. Test methods

2.1. Test program

The experiment considers four types of rubber particle sizes (), namely 10 mesh, 20 mesh, 40 mesh, and 100 mesh, and takes into account four rubber particle content () namely 5 %, 10 %, 15 %, and 20 %, with a volume ratio used for the content. Rubber particles are mixed into loess by external mixing method, the freeze-thaw specimen are subjected to dynamic triaxial tests at unsaturated moisture content to determine the dynamic shear modulus () and damping ratio ().

The test is divided into three stages, the first stage is determination of mix proportion moisture content of rubber particle-loess. According to Article 13 of the “Standard for Soil Test Methods” (GBT50123-2019), a light compaction test is conducted to determine the optimum moisture content and saturated moisture content. Take one-third of the difference between the saturated moisture content and the optimum moisture content as a gradient. The four moisture content values obtained by subtracting the gradient from the saturated moisture content for four consecutive times are used as the mix proportion moisture content (as shown in Table 1). And the density of rubber particle-loess is determined under the conditions of light compaction test. The second stage is the freeze-thaw cycle test. The temperature range of freeze-thaw is –20 ℃-20 ℃, and the number of freeze-thaw cycles () is divided into five types: 0, 1, 3, 6, and 9. Each cycle lasts for 12 hours, including 6 hours of freezing and 6 hours of melting. The third stage is dynamic triaxial loading stage. At this stage, the confining pressure () is applied at 50 kPa, 100 kPa, and 200 kPa, and the axial loading is controlled by deviator stress. The deviator stress loading is divided into six levels: 3 kPa, 5 kPa, 10 kPa, 20 kPa, 40 kPa, and 240 kPa, with 10 vibrations per loading, a loading frequency of 1Hz, and sine wave control. In the test, the remolded loess is designed as a reference, and its mix proportion moisture content is 11.14 %, 12.20 %, 13.26 %, and 14.32 %, respectively.

It should be noted that the dynamic triaxial and freeze-thaw cycle test conditions in this study are carefully designed to simulate the environmental conditions that infrastructure in Inner Mongolia’s loess areas may encounter. The confining pressures applied in the dynamic triaxial tests (50 kPa, 100 kPa, 200 kPa) cover the stress range that shallow to deep foundations may bear, effectively simulating the stress state of foundation soil at different depths. The number of freeze-thaw cycles (0, 1, 3, 6, 9) is set based on the severe and large temperature difference climate in Inner Mongolia's winter. Each cycle lasting 12 hours (6 hours freezing, 6 hours thawing) aims to simulate the freeze-thaw effect caused by temperature changes in a day, thus studying the performance changes of rubber particle-loess under different freeze-thaw cycles.

Moreover, the selected rubber particle content range (5 %, 10 %, 15 %, 20 %) and size range (10 mesh, 20 mesh, 40 mesh, 100 mesh) are determined based on relevant literature. Comprehensive research findings indicate that the selection of rubber particle size and content in loess improvement should balance engineering requirements and economic benefits. A content range of 5 % to 15 % generally enhances the compactness and strength of loess [19], with 40-mesh rubber particles proving superior in improving soil structure, shear strength, and compactness [20]. Lower contents (5 %-10 %) can significantly reduce the usage of other agents and enhance soil properties, offering economic viability [14]. However, contents exceeding 20 % can lead to increased porosity, reduced compactness, and strength due to the formation of a separate rubber particle framework. Therefore, controlling the rubber particle content within 5 % to 20 % optimizes performance, avoids degradation, and ensures environmental sustainability and cost-effectiveness [21]. The selected rubber particle sizes of 10 mesh, 20 mesh, 40 mesh, and 100 mesh aim to comprehensively evaluate the effects on loess properties. Notably, 40 mesh has demonstrated superior performance in previous studies, while the others span a spectrum from coarse to fine particles. Therefore, the selected rubber particle content and size range in this study have a practical significance, aiming to provide scientific and reasonable parameter guidance for the improvement of loess in Inner Mongolia using waste tire rubber particles.

Table 1The mix proportion moisture content of rubber particle-loess

Rubber particle content (%) | Rubber particle size (mesh) | Moisture content (%) | |||

Low | Optimum | Medium | High | ||

5 | 10 | 9.37 | 11.05 | 12.73 | 14.41 |

20 | 10.15 | 11.72 | 13.29 | 14.86 | |

40 | 11.36 | 12.79 | 14.22 | 15.65 | |

100 | 12.12 | 13.51 | 14.90 | 16.29 | |

10 | 10 | 9.73 | 11.53 | 13.33 | 15.13 |

20 | 9.71 | 11.66 | 13.61 | 15.56 | |

40 | 9.72 | 11.96 | 14.20 | 16.44 | |

100 | 10.42 | 12.44 | 14.46 | 16.48 | |

15 | 10 | 8.44 | 10.74 | 13.04 | 15.34 |

20 | 9.14 | 11.33 | 13.52 | 15.71 | |

40 | 8.93 | 11.51 | 14.09 | 16.67 | |

100 | 8.76 | 11.60 | 14.44 | 17.28 | |

20 | 10 | 8.63 | 11.01 | 13.39 | 15.77 |

20 | 9.35 | 11.59 | 13.83 | 16.07 | |

40 | 8.88 | 11.63 | 14.38 | 17.13 | |

100 | 8.72 | 11.67 | 14.62 | 17.57 | |

Note: 1) The second moisture content value (column 2) is the optimum moisture content 2) The differences between the moisture content values (Low, Optimum, Medium, High) are one-third of the difference between the saturated moisture content and the optimum moisture content 3) In the following figures, moisture content is represented by labels Low, Optimum, Medium and High, corresponding to the columns in this table | |||||

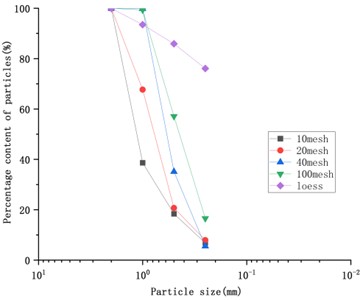

2.2. Test material

The rubber particles are taken from the finished rubber particles of waste tires produced by Jiubaoshi Powder Factory in Hebei Province, as shown in Fig. 1. The test loess is taken from the Helingeer area of Hohhot city, China, and the soil extraction site is shown in Fig. 2. The soil particle density of loess is 2.62, the plastic limit is 15.5%, the liquid limit at a cone depth of 10 mm is 24.7 %, the liquid index is 9.2, and the natural moisture content is 7.25 %. It is determined that the soil is silt. The grading curves of loess and rubber particles are shown in Fig. 3.

Fig. 1Rubber particles

a) 10mesh

b) 20 mesh

c) 40 mesh

d) 100 mesh

Fig. 2Sampling point layout of loess

Fig. 3Grading curve

2.3. Test equipment

The Dynamic Triaxial Testing System (DYNTTS) is developed and manufactured by GDS in the UK, as shown in Fig. 4(a). Its maximum axial dynamic loading is 6 kN, accuracy is 1 kPa, axial displacement stroke is ±50 mm, axial displacement measurement resolution is 0.08 μm, axial displacement measurement accuracy is 0.07 %, axial force measurement accuracy is greater than 0.1 % FRO, and the confining pressure control subsystem is completed by the DYNTTS digital pressure/volume (200 cc/2 MPa) controller, with a resolution of up to 3 kPa. The maximum frequency of dynamic loading is 5 Hz, with sine wave dynamic control, and unconsolidated undrained shear test is adopted.

The freeze-thaw cycle test equipment utilizes the LRHS-225D high-low temperature alternating and humidity test chamber, as shown in Fig. 4(b), with a working temperature range of –70-150 ℃ and a humidity range of 0-10 0%.

2.4. Specimen preparation

The air-dried loess is sieved through a 2 mm mesh and mixed evenly with rubber particles at the designed content, as shown in Fig. 5(a), and is mixed with water using mix proportion moisture content and allowed to cure for 24 hours. By using quality control method, the soil mixture is loaded into the triaxial compaction mold in three times and compacted. When adding in stages, chiseling treatment is required. After compaction, the specimen has a diameter of 50 mm and a height of 100 mm, as shown in Fig. 5(b). The molded specimen is wrapped in a fresh-keeping bag and subjected to freeze-thaw cycles according to the set number of freeze-thaw cycles. Post freeze-thaw treatment, the specimen (as shown in Fig. 5(c)) can be used for dynamic triaxial tests.

Fig. 4Test equipment

a) DYNTTS

b) Freeze-thaw meter

Fig. 5Triaxial specimen preparation

a) Loess mixed with rubber particles

b) Triaxial specimen

c) Post freeze-thaw specimen

3. Analysis of test results

3.1. Compactness analysis

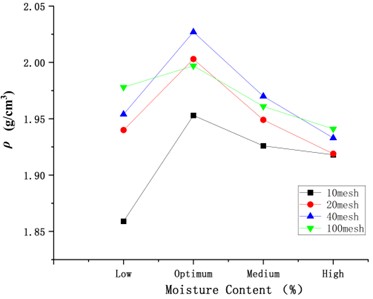

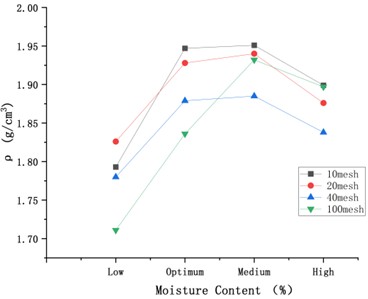

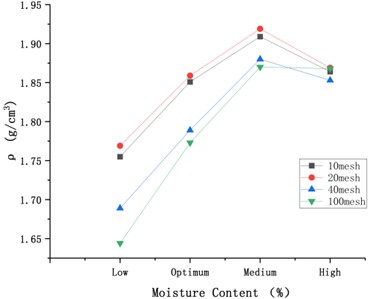

When rubber particles of the same density are mixed into loess of the same dry density, the compactness of the specimen varies under the same compaction work but different moisture content conditions. The density reflects its compactness to a certain extent, and the higher the density, the better the compactness. This experiment used a light compaction test to determine the densities of loess specimens with different content and size of added rubber particles. Fig. 6(a-d) show relationship curve between density and moisture content of rubber particle-loess under different content conditions. According to the figure, the density of rubber particle-loess shows a tendency of increasing first and then decreasing with the increase of moisture content. Under different rubber particle content conditions, the maximum density of rubber particle-loess corresponds to different rubber particle sizes. The density of rubber particle-loess is maximum at 5 % rubber particle content and 40 mesh particle size. Therefore, from the perspective of compactness, the combination with a rubber particle content of 5 % and a particle size of 40 mesh has the best effect. In this state, rubber particle-loess is the most dense, with high strength and resistance to deformation.

The reason for this is that the addition of rubber particles first changes the grading curve of loess. This change is because rubber particles, as a new type of particle, are of different sizes from those of the loess particles (As shown in Fig. 1), thus forming a new combination of particles after mixing. When rubber particles are evenly dispersed in loess, they can effectively fill the gaps between soil particles. Especially the 40 mesh rubber particles, which are of moderate size, can not only fill the gaps between larger soil particles, but also form good interlocking with smaller soil particles. This interlocking effect creates a more tightly packed structure between particles of different sizes, resulting in a decrease in soil porosity and an increase in density.

Fig. 6The relationship curve between density and moisture content of rubber particle-loess under different rubber content conditions. (Note: Moisture content (Low, Optimum, Medium and High) correspond to mix proportion moisture content in Table 1)

a)5 %

b)10 %

c)15 %

d)20 %

3.2. Dynamic shear modulus analysis

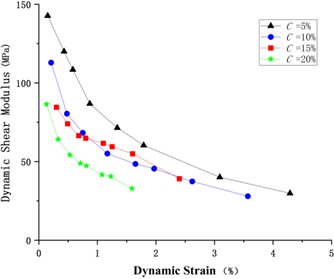

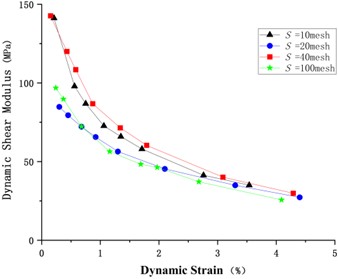

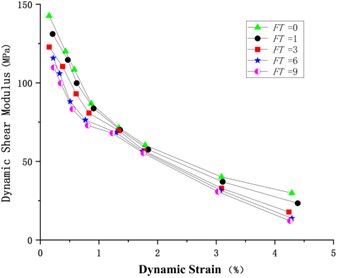

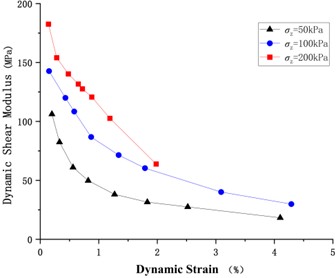

Dynamic shear modulus is an indication of the ability of soil to resist dynamic shear deformation, and is also an important indicator for evaluating the dynamic shear deformation of soil. Fig. 7 shows the relationship curve between dynamic shear modulus and dynamic strain, according to the figure, the dynamic shear modulus decays with the increase of dynamic strain, similar to the variation of dynamic shear modulus of loess [22]. The dynamic stress and strain exhibit a strain softening behavior, which is distinct from the static properties of loess [23]. At small strains (less than 0.8 %-1 %), the dynamic shear modulus decays more rapidly than at large strains (exceeding 1 %), where its decay rate gradually slows down and eventually becomes flat. It indicates that the rubber particle-loess is initially relatively hard, but as the deformation increases, the soil structure gradually adjusts, and its stiffness subsequently decreases.

Fig. 7(a) shows the relationship between dynamic shear modulus and dynamic strain at different rubber particle content conditions. According to the figure, although the curves for 10 % and 15 % rubber particle content intersect to some extent, the overall position of the curve shifts downward as the rubber particle content increases. Under the same dynamic strain conditions, the specimen with 5 % rubber particle content exhibits the highest dynamic shear modulus. Fig. 7(b) shows the relationship between dynamic shear modulus and dynamic strain under different rubber particle sizes conditions. It indicates that under the same dynamic strain conditions, the dynamic shear modulus is highest for 40 mesh rubber particles, followed by 10 mesh, with an alternating situation between 10 mesh and 100 mesh. Fig. 7(c) shows the relationship between dynamic shear modulus and dynamic strain under different freeze-thaw cycles. It indicates that under the same dynamic strain conditions, as the number of freeze-thaw cycles increases, the dynamic shear modulus decreases. Fig. 7(d) shows the relationship between dynamic shear modulus and dynamic strain under different confining pressure conditions. It indicates that, under the same dynamic strain conditions, the greater the confining pressure, the greater the dynamic shear modulus, which conforms to the variation law of loess dynamic properties [24]. Adding rubber particles with a content of 5 % and a particle size of 40 mesh to loess results in a relatively high dynamic shear modulus. Therefore, a content of 5 % and a particle size of 40 mesh are the ideal content and particle size.

Fig. 7The relationship curve between dynamic shear modulus and dynamic strain

a) Different particle content ( 100 kPa, 40 mesh, = 0)

b) Different particle sizes (100 kPa, 5 %, 0)

c) Different number of freeze-thaw cycles (100 kPa, 5 %, 40 mesh)

d) Different confining pressure (5 %, 40 mesh, 0)

3.3. Damping ratio analysis

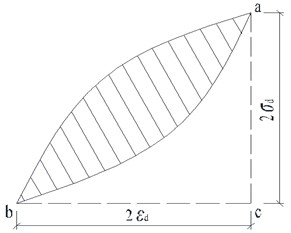

The damping ratio, which characterizes the energy dissipation of soil under cyclic loading, significantly influences the vibration response of soil [25] and the ground vibration parameters of the site [26]. According to the dynamic triaxial test, the dynamic stress-dynamic strain hysteresis loop is drawn, as shown in Fig. 8. The axial damping ratio can be calculated according to Eq. (1), and then the relationship between the damping ratio of rubber particle-loess and moisture content, freeze-thaw cycle times, confining pressure, and original soil damping ratio can be determined:

where: – damping ratio; – dynamic stress-dynamic strain hysteresis loop area (cm2), area of the shaded part in Fig. 8; – area (cm2) of right triangle abc in Fig. 8.

Fig. 8Dynamic stress-dynamic strain hysteresis loop

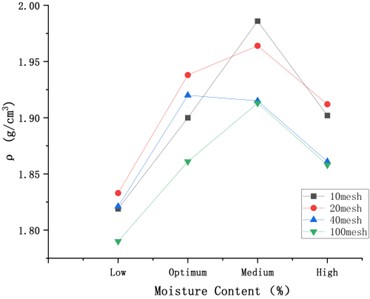

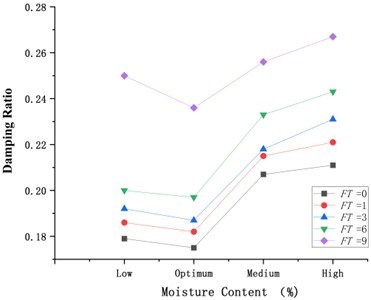

3.3.1. Relationship between damping ratio and moisture content

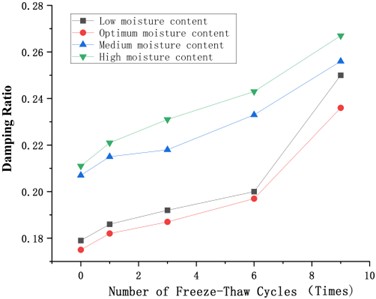

Fig. 9(a) shows the relationship between damping ratio and moisture content under different freeze-thaw cycles, with the x-axis representing the moisture content for mix proportions 1, 2, 3, and 4. According to the figure, under the same freeze-thaw cycle conditions, the damping ratio of rubber particle-loess shows a trend of first decreasing and then increasing as the moisture content increases. The damping ratio is smallest at the optimum moisture content and largest at the fourth mix proportion moisture content (close to the saturation moisture content). The reason for this is that the presence of water can enhance the fluidity and plasticity of the soil when the moisture content of the rubber particle-loess is high. Moisture can increase the lubrication between soil particles, leading to increased energy dissipation under stress, and thus improving the damping ratio. High moisture content can also increase pore water pressure, which may reduce the effective stress of the soil. The reduction in effective stress typically leads to a decrease in the soil’s shear strength, increasing its deformation capacity and energy dissipation under dynamic loads, thus enhancing the damping ratio. Rubber particle-loess with higher moisture content exhibits a looser structure, reducing the shear strength of the soil. This looseness also increases the deformation capacity of the soil, allowing it to absorb and dissipate more energy during dynamic loading, leading to an increase in the damping ratio. At the optimum moisture content, the rubber particle-loess mixture reaches its densest state, the shear strength of the soil is at its highest, its deformation capacity is reduced, and less energy is absorbed under dynamic loading, resulting in the smallest damping ratio.

3.3.2. Relationship between damping ratio and number of freeze-thaw cycles

Fig. 9(b) shows the relationship between damping ratio and the number of freeze-thaw cycles under different moisture content conditions. According to the figure, under the same moisture content conditions, the damping ratio increases with the number of freeze-thaw cycles. This indicates that freeze-thaw action enhances the dynamic load absorption capacity of rubber particle-loess, thereby improving its seismic performance. This is due to the freeze-thaw cycles that lead to the destruction of soil structure [27] and changes in pore water pressure. Freezing and thawing can cause water to freeze and thaw, alter the characteristics of pore water in soil, increase water fluidity, and promote changes in pore water. At the same time, freeze-thaw cycles can cause the rearrangement and loosening of soil particles, reducing the soil's internal friction angle and increasing damping. As the number of freeze-thaw cycles increases, the soil may experience more microscopic damage, which will also improve its damping performance. The damping ratio curves for the 3rd and 4th mix proportion moisture contents are significantly higher than those for the other two mix proportion, and thus are more affected by freeze-thaw cycles at higher moisture contents, where water plays a significant role in the changes.

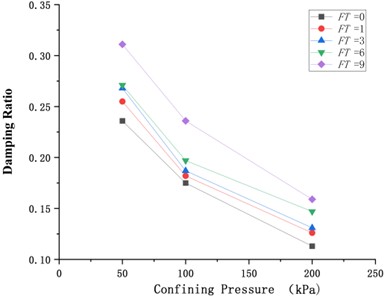

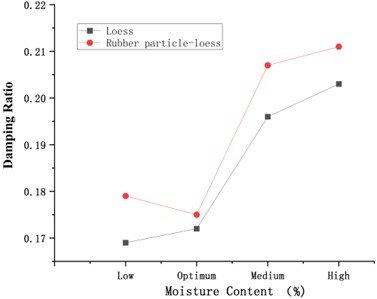

Fig. 9The relationship curves between damping ratio and various factors. (Note: Moisture content (Low, Optimum, Medium and High) corresponds to mix proportion moisture content in Table 1)

a) Different moisture content (100 kPa)

b) Different number of freeze-thaw cycles (100 kPa)

c) Different confining pressure (Optimum moisture content)

d) Rubber particle-loess vs. loess (0)

3.3.3. Relationship between damping ratio and confining pressure

Fig. 9(c) shows the relationship between the damping ratio and the confining pressure under different freeze-thaw cycle times, according to the figure, according to the figure, under the same freeze-thaw cycle conditions, the damping ratio decreases with increasing confining pressure, which is consistent with the variation law of the damping ratio of soft clay under cyclic loading [28]. When the confining pressure is less than 100 kPa, the damping ratio attenuation rate is relatively fast. However, when the confining pressure exceeds 100 kPa, the damping ratio attenuation rate slows down. The reason for this is that the effective stress in the soil increases when the confining pressure is increased, thus increasing the soil's shear strength. Higher shear strength implies that the soil is less likely to deform under stress, which results in a lower capacity to dissipate energy, and consequently, a lower damping ratio. The stiffness of the soil also increases under high confining pressures. This increased stiffness implies that the soil deforms less under the same dynamic loading, which reduces energy dissipation and leads to a reduction in the damping ratio. Therefore, under dynamic loading, such as during earthquakes or vibrations, soils with high confining pressures typically exhibit lower damping capacity, implying that energy is less likely to be dissipated in the transfer process.

3.3.4. Comparative analysis of damping ratio between rubber particle-loess and plain soils

Fig. 9(d) shows the relationship between the damping ratio of rubber particle-loess and plain soil and the mix proportion moisture content, according to the figure, the damping ratio of rubber particle-loess and plain soil is relatively small at the first and second mix proportion moisture content. When the mix proportion moisture content is greater than the optimum moisture content, the damping ratio increases significantly. Under the same mix proportion moisture content condition, the damping ratio of rubber particle-loess is greater than that of the plain soil. The reason for this is that rubber particles themselves possess high elasticity and can absorb and dissipate more energy than plain soil under dynamic loading, thereby increasing the damping ratio.

3.3.5. Relationship between damping ratio and compactness

Comparing Fig. 6(a) and Fig. 9(a), it can be seen that with the increase of moisture content, the compactness of rubber particle-loess first increases and then decreases, while the damping ratio shows a trend of first decreasing and then increasing, and the damping ratio is negatively correlated with the compactness. The reason for this is that as compactness increases, the soil's pores decrease, the contact area between soil particles increases, and there are more contact points. This results in stress waves propagating faster and deeper in the soil, with less energy attenuation, and therefore lower damping. The compactness of rubber particle-loess with a 5 % content and a 40 mesh particle size is the highest, thus its damping ratio is the smallest. However, at this time, the damping ratio of rubber particle-loess is higher than that of plain soil. Therefore, incorporating rubber particles can improve the damping ratio of loess, which has a beneficial effect on seismic performance. According to the changes of the dynamic shear modulus and damping ratio of rubber particle-loess, it can be inferred that adding 5 %, 40 mesh rubber particles in loess can alter its structure, resulting in a relatively large dynamic shear modulus. The high dynamic shear modulus of rubber particle-loess implies that its structure is more stable and the friction between particles is greater. Moreover, the damping ratio of rubber particle-loess is larger than that of plain soil, which contributes to energy dissipation and the reduction of vibration amplitude of the structure when subjected to dynamic loading. Therefore, rubber particle-loess not only possesses high strength but also exhibits a higher damping ratio compared to plain soil and has good seismic resistance.

4. Microstructure analysis

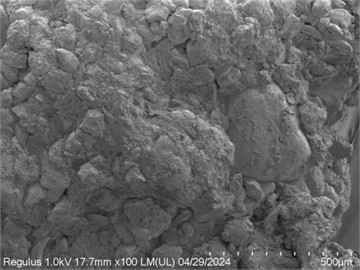

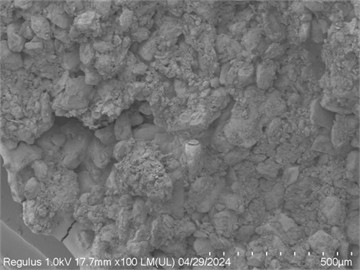

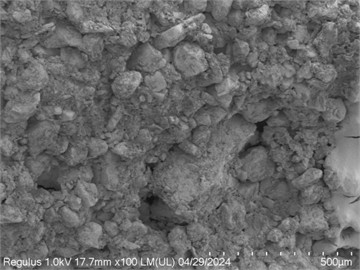

4.1. Analysis of microstructure changes under freeze-thaw action

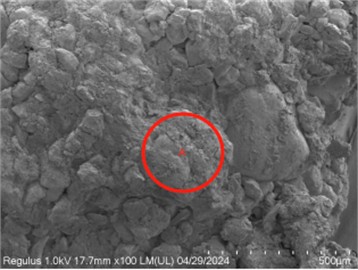

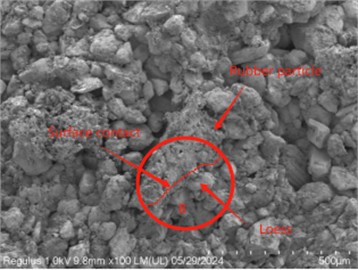

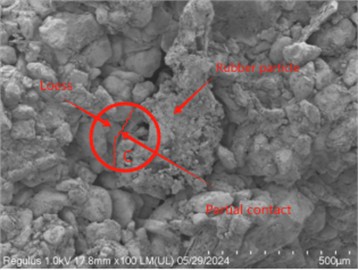

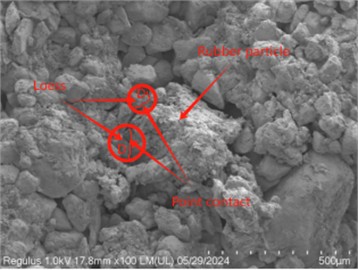

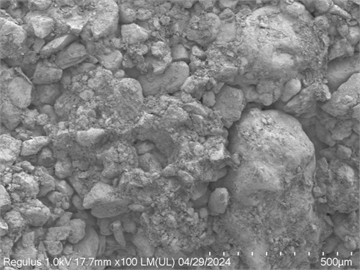

The SEM images reveal the microstructural changes of rubber particle-loess with increasing freeze-thaw cycles (As shown in Fig. 10). As freeze-thaw cycles increases, the contact between rubber and loess particles becomes looser. At FT = 0, rubber and loess particles are tightly bonded in full contact, forming a dense structure with few pores. This tight contact enhances the dynamic shear modulus of rubber particle-loess, giving it high stiffness and strength. As freeze - thaw cycles increase (FT = 1, 6, and 9), the bond weakens, and contact types change from surface contact to partial contact and point contact. These changes lead to a looser structure and larger pores. At FT = 9, the contact is very loose, with many pores and mainly point contact. The looser structure reduces the contact area and friction between particles, lowering the dynamic shear modulus. Meanwhile, larger pores and looser particle arrangement increase energy dissipation, raising the damping ratio.

4.2. Analysis of microstructure changes under the influence of moisture content

The SEM images illustrate how the microstructure of rubber particle-loess changes with varying moisture content (As shown in Fig. 11). Under optimum moisture content conditions, rubber particles are tightly bonded with loess particles, forming a dense structure with minimal pores. Rubber particles are evenly distributed and effectively fill the gaps between loess particles (As shown in Fig. 11(b)). The dense microstructure results in a high dynamic shear modulus, while the tight structure limits particle displacement, reducing energy dissipation and leading to a low damping ratio. Under low moisture content conditions, the bond between rubber and loess particles weakens slightly, creating small pores and loosening. Rubber particles still provide some filling but less effectively than at optimum moisture content (As shown in Fig. 11(a)). The slight loosening reduces the dynamic shear modulus, while the appearance of small pores increases energy dissipation, causing the damping ratio to rise. At higher moisture content, the bond between rubber and loess particles significantly weakens, resulting in larger pores and more pronounced loosening. The filling effect of rubber particles diminishes, and separation may occur locally (As shown in Fig. 11(c) and Fig. 11(d)). The substantial loosening leads to a significant decrease in dynamic shear modulus, while the increased pore size enhances energy dissipation, resulting in a high damping ratio.

Fig. 10SEM images of rubber particle-loess under different freeze-thaw cycles: a) full contact, b) surface contact, c) partial contact, d) point contact

a) FT = 0

b) FT = 1

c) FT = 6

d) FT = 9

These microstructural changes provide insights into the mechanisms underlying the observed macroscopic trends in dynamic shear modulus and damping ratio with freeze-thaw action and varying moisture content.

5. Conclusions

In this paper, the dynamic properties of rubber particle-loess are studied using dynamic triaxial test and the change of compactness is deeply explored. The study results indicate that:

1) The addition of rubber particles significantly enhances the engineering properties of loess, particularly in the areas of dynamic shear modulus, damping ratio, and compactness. When the rubber particle content is 5 % and the size is 40 mesh, the dynamic shear modulus and damping ratio of rubber particle-loess reach their optimal values, and the compactness also reaches its maximum value. This improvement not only enhances the strength of loess, but also strengthens its energy dissipation ability under dynamic loading by increasing the damping ratio, thereby enhancing its seismic performance. In addition, an increase in compactness also indicates that the soil structure is more compact, the interparticle porosity is reduced, and this helps to improve the soil’s overall bearing capacity and deformation resistance.

Fig. 11SEM images of rubber particle-loess under different moisture content

a) Low moisture content

b) Optimum moisture content

c) Medium moisture content

d) High moisture content

2) The dynamic shear modulus decays with increasing dynamic strain. At small strains (less than 0.8 %-1 %), the dynamic shear modulus decays more rapidly than at large strains (exceeding 1 %), where its decay rate gradually slows down and eventually becomes flat. In addition, increasing the content of rubber particles and the number of freeze-thaw cycles will reduce the dynamic shear modulus, while increasing confining pressure will increase it.

3) Damping ratio is an important indicator of energy dissipation in soils under dynamic loading. It is found that the damping ratio of rubber particle-loess varies with changes in moisture content, the number of freeze-thaw cycles and confining pressure. Specifically, the damping ratio first decreases and then increases with the increase of moisture content, and the damping ratio is minimum at the optimum moisture content. The increase of the number of freeze-thaw cycles can lead to the increase of the damping ratio, which indicates that freeze-thaw action can enhance the dynamic loading absorption capacity of the rubber particle-loess. Conversely, the increase of the confining pressure can lead to the decrease of the damping ratio. At the same time, the damping ratio of rubber particle-loess is larger than that of plain soil, and its energy dissipation capacity is greater than that of plain soil.

4) Recommendations for practical applications and future research. For practical applications, the optimized rubber particle-loess (5 % content, 40 mesh) is recommended for infrastructure projects in Inner Mongolia, such as road subgrades, railway foundations, and building bases, to enhance seismic resistance and mitigate freeze-thaw damage. This technology can also be extended to other cold regions, promoting both engineering resilience and sustainable recycling of waste tires.

It is suggested that future research be expanded to investigate the long-term stability of rubber particle-loess under ultra long freeze-thaw cycles (exceeding 9 cycles) and extreme low temperatures (below –20 ℃). Additionally, explore the synergistic effects between rubber particles and other recycled materials, such as construction waste and biomass ash. Through the optimization of multi-material ratios and research on adaptability to extreme environments, more universally applicable composite improvement strategies can be developed.

s

References

-

Z. Kang, J. Kang, G. Deng, J. Zheng, L. Wang, and H. Gao, “The self-weight collapsible characteristics of loess in Xi’an Urban Area,” (in Chinese), Chinese Journal of Geotechnical Engineering, Oct. 2024.

-

S. Liu, N. Liu, J. Li, and F. Fei, “Experimental study on dynamic shear modulus and damping ratio of loess considering disturbance,” in Journal of Physics: Conference Series, Vol. 2424, No. 1, p. 012009, Jan. 2023, https://doi.org/10.1088/1742-6596/2424/1/012009

-

Y. Song and L. Yang, “Mechanical properties of loess and filling materials of high-speed railway vibration isolation trench in loess area,” Science of Advanced Materials, Vol. 14, No. 4, pp. 760–771, Apr. 2022, https://doi.org/10.1166/sam.2022.4260

-

W. Xiong and H. Liu, “Study on building foundation reinforcement in collapsible loess area,” (in Chinese), Railway Construction Technology, Oct. 2024.

-

Q. Wang et al., “Dynamic constitutive relationship of lignin-modified loess,” (in Chinese), Chinese Journal of Geotechnical Engineering, Vol. 45, pp. 235–240, Dec. 2023, https://doi.org/10.11779/cjge2023s20034

-

J. Bai, Y. Zhang, and S. Wu, “Review study of physical and mechanical characteristics on mixed soil with scrap tire rubber particles,” Jordan Journal of Mechanical and Industrial Engineering, Vol. 14, No. 1, pp. 71–79, Mar. 2020.

-

Z. Wang, X. Gan, D. Wu, E. Zhou, X. Zuo, and Q. Wang, “Research on the test of shear strength and dynamic deformation characteristic of saturated rubber sand,” (in Chinese), Engineering Technology Research, Vol. 9, No. 8, pp. 109–111, May 2024, https://doi.org/10.19537/j.cnki.2096-2789.2024.08

-

A. Deng and J. Feng, “Effect of scrap tire bead addition on shear behavior of sand,” (in Chinese), Journal of PLA University of Science and Technology, Vol. 10, No. 5, pp. 483–487, Oct. 2009, https://doi.org/10.3969/j.issn.1009-3443.2009.05.015

-

J.-G. Bai, W.-Q. Kou, and H.-J. Li, “Numerical simulation of the deformation behavior of a composite foundation consisting of rubber particle loess-CFG under dynamic loading,” Journal of Vibroengineering, Vol. 26, No. 5, pp. 1237–1248, Aug. 2024, https://doi.org/10.21595/jve.2024.24110

-

Z. Liu, X. Du, D. Liu, J. Jia, C. Liu, and J. Bai, “Experimental study on unconfined compressive strength of loess mixed with rubber particles,” (in Chinese), Construction Engineering Technology and Design, No. 2, p. 443, Feb. 2020, https://doi.org/10.12159/j.issn.2095-6630.2020.06.3980

-

Z. Hu, Z. Liu, Z. Zhang, J. Xu, and X. Yan, “Test on influence of rubber powder on dynamic mechanic properties of manipulated loess,” (in Chinese), Journal of Chang’an University (Natural Science Edition), Vol. 33, No. 4, pp. 62–67, Apr. 2013, https://doi.org/10.19721/j.cnki.1671-8879.2013.04.011

-

S. Chai, X. Li, Y. Li, J. Liu, D. Quan, and Z. Fan, “Experimental study on dynamic properties of loess improved by rubber particles and EICP technology,” (in Chinese), Advanced Engineering Science, Vol. 56, No. 3, pp. 134–146, Feb. 2024, https://doi.org/10.15961/j.jsuese.202300961

-

Y. Chen, S. Chai, D. Cai, W. Wang, X. Li, and J. Liu, “Experimental study on shear mechanical properties of improved loess based on rubber particle incorporation and EICP technology,” Frontiers in Earth Science, Vol. 11, No. 11, p. 2023, Sep. 2023, https://doi.org/10.3389/feart.2023.1270102

-

F. Wang, “Experimental study on improvement of collapsible loess foundation with fly ash + lime + waste tire rubber particles,” (in Chinese), Aging and Application of Synthetic Materials, Vol. 51, No. 4, pp. 86–89, Aug. 2022, https://doi.org/10.16584/j.cnki.issn1671-5381.2022.04.046

-

Y. Sun and F. Zhao, “Improvement of collapsible loess by rubber particulate lime-soil,” (in Chinese), Journal of Hebei Institute of Architecture and Civil Engineering, Vol. 41, No. 2, pp. 83–87, Jun. 2023, https://doi.org/10.3969/j.issn.1008-4185.2023.02.015

-

W.-Q. Kou, J.-G. Bai, H.-J. Li, and Q.-H. Liu, “Study on compaction characteristics and discrete element simulation for rubber particle-loess mixed soil,” Insight – Civil Engineering, Vol. 7, No. 1, p. 618, Jul. 2024, https://doi.org/10.18282/ice.v7i1.618

-

A. H. Abdel-Rahman and S. Yassin, “Sustainable geotechnical design for Al-Azhar park, Cairo,” in Geo-Chicago 2016, Reston, VA: American Society of Civil Engineers, 2016, pp. 712–721, https://doi.org/10.1061/9780784480120.072

-

A. Assadollahi and J. Crocker, “Consolidation properties of local Memphis loess when crumb rubber is used as a fill material,” in IFCEE 2018, pp. 186–194, Jun. 2018, https://doi.org/10.1061/9780784481592.019

-

W. Wang, S. Chai, and Y. Chen, “A Method for reinforcing loess with rubber particles combined with EICP,” China Patent CN118745728A, 2024.

-

Z. Wang et al., “Experimental study on shear strength and dynamic deformation characteristics of saturated rubber-sand,” (in Chinese), Engineering Technology Research, Vol. 9, No. 8, pp. 109–111, Apr. 2024, https://doi.org/10.19537/j.cnki2096-2789.2024.08.035

-

C. Zuo, J. Zhou, and W. Deng, “Review on improvement effect evaluation of expansive soil mixed with rubber particles,” (in Chinese), Shanxi Architecture, Vol. 36, No. 25, pp. 83–84, Sep. 2010, https://doi.org/10.13719/j.cnki.cn14-1279/tu.2010.25.082

-

S. Shao et al., “Study on complex dynamic stress shear yield and failure strength of loess,” (in Chinese), Chinese Journal of Geotechnical Engineering, Vol. 46, No. 9, pp. 62–67, Sep. 2024, https://doi.org/10.19721/j.cnki.1671-8879.2024.09.011

-

S. Huang, L. Lei, X. Guo, Z. Zhang, X. Luo, and Z. Wang, “The influence on strength characteristics of frozen loess under pressure freeze-thaw cycle,” (in Chinese), Forest Engineering, Vol. 40, No. 5, pp. 181–189, May 2024, https://doi.org/10.7525/j.issn.1006-8023.2024.05.019

-

Y. Zhang and J. Qian, “Analysis of dynamic properties of loess in Weibei area under cyclic loading,” (in Chinese), The Journal of Xi’an University of Architecture and Technology, Vol. 56, No. 4, pp. 535–543, Sep. 2024, https://doi.org/10.15986/j.1006-7930.2024.04.007

-

H. Yang, L. Liu, H. Liu, P. Gao, and Y. Chen, “Tests for dynamic modulus and damping ratio of high polymer cementitious gobi soil,” (in Chinese), Journal of Vibration and Shock, Vol. 42, No. 3, pp. 12–20, Feb. 2023, https://doi.org/10.13465/j.cnki.jvs.2023.03.002

-

D. Song, H. Liu, and S. Zhao, “Effects of sand damping ratio determination methods induced from dynamic triaxial tests on ground motion parameters,” (in Chinese), Earthquake Engineering an Engineering Dynamics, Vol. 43, No. 6, pp. 194–202, Jan. 2023, https://doi.org/10.13197/j.eeed.2023.0621

-

J. Xu, Z. Wang, J. Ren, and J. Yuan, “Comparative test study on deterioration mechanism of undisturbed and remolded loess during the freeze-thaw process,” (in Chinese), Chinese Journal of Underground Space and Engineering, Vol. 14, No. 3, pp. 643–649, May 2018.

-

Z. Wei, Y. Zhu, T. Wang, Y. Deng, and H. Zhuang, “Damping ratio characteristics and simplified calculation method of soft clay under metro operation cyclic loading,” (in Chinese), Journal of Civil and Environmental Engineering, Vol. 46, No. 5, pp. 204–210, Oct. 2024, https://doi.org/10.11835/j.issn.2096-6717. 2022.073

About this article

The authors would like to thank Inner Mongolia Autonomous Region Natural Science Foundation (2023LHMS05048) for this study.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Yan Zhang is mainly responsible for writing-original draft preparation. Shao-Jun Hu is mainly responsible for conducting experiments and data curation. Jian-Guang Bai is mainly responsible for funding acquisition and project administration. Wen-Qi Kou is mainly responsible for methodology. Hai-Jun Li is mainly responsible for writing-review and editing.

The authors declare that they have no conflict of interest.